slurry pump spare parts supplier

Latest articles

- transport solids hydraulically

slurry pump spare parts supplier...

slurry pump spare parts supplier 【slurry pump spare parts supplier】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

slurry pump spare parts supplier...

slurry pump spare parts supplier 【slurry pump spare parts supplier】

Read More- By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

slurry pump spare parts supplier...

slurry pump spare parts supplier 【slurry pump spare parts supplier】

Read MoreDamage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

slurry pump spare parts supplier...

slurry pump spare parts supplier 【slurry pump spare parts supplier】

Read MoreMill sump

slurry pump spare parts supplier...

slurry pump spare parts supplier 【slurry pump spare parts supplier】

Read MoreThe discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

slurry pump spare parts supplier...

slurry pump spare parts supplier 【slurry pump spare parts supplier】

Read More1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

slurry pump spare parts supplier...

slurry pump spare parts supplier 【slurry pump spare parts supplier】

Read MoreSlurry Pump

slurry pump spare parts supplier...

slurry pump spare parts supplier 【slurry pump spare parts supplier】

Read MoreSlurry Pump selection

slurry pump spare parts supplier...

slurry pump spare parts supplier 【slurry pump spare parts supplier】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

slurry pump spare parts supplier...

slurry pump spare parts supplier 【slurry pump spare parts supplier】

Read More

Popular articles

- The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

- Slurry Pump

- >Vertical Slurry Pump

- testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

- Although the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

- How to Choose a Dredging Pump or Slurry Pump

Latest articles

-

Slurry Pump

-

Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

-

Slurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

-

Step 3

-

Slurry Pump Impeller

-

Consider the pump components

Links

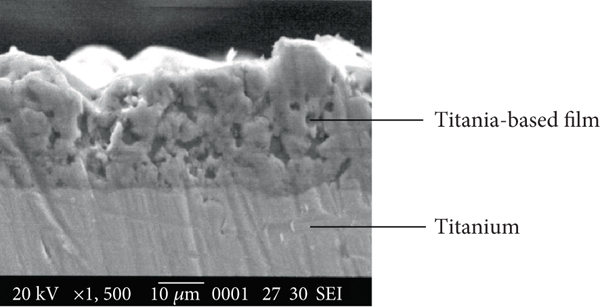

In a study published in 2022 in the journal Particle and Fibre Technology, researchers examined the impact of maternal exposure to titanium dioxide nanoparticles in newborn offspring mice. They found that “a chronic exposure to TiO2 NPs during pregnancy alters the respiratory activity of offspring, characterized by an abnormally elevated rate of breathing.” Breathing was also shown to be “significantly and abnormally accelerated,” and the ability for neural circuitry to effectively adjust breathing rates was impaired. The researchers concluded: “Our findings thus demonstrate that a maternal exposure to TiO2 NPs during pregnancy affects the normal development and operation of the respiratory centers in progeny.”

Among the raw materials for coating production, titanium dioxide is more ideal, followed by lithopone. The covering power of lithopone is only that of titanium dioxide, and the price of lithopone is much lower than that of titanium dioxide, so lithopone still occupies a large market share.

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials talc titanium dioxide manufacturer. This is because talc provides reinforcement, while titanium dioxide enhances the cross-linking density of the rubber molecules, making them more resistant to deformation under stress.

talc titanium dioxide manufacturer. This is because talc provides reinforcement, while titanium dioxide enhances the cross-linking density of the rubber molecules, making them more resistant to deformation under stress.≤0.3

The assessment was conducted following a rigorous methodology and taking into consideration many thousands of studies that have become available since EFSA’s previous assessment in 2016, including new scientific evidence and data on nanoparticles.

Environmental concerns, stringent regulations, and fluctuations in raw material prices have posed hurdles for the industry Environmental concerns, stringent regulations, and fluctuations in raw material prices have posed hurdles for the industry

Environmental concerns, stringent regulations, and fluctuations in raw material prices have posed hurdles for the industry Environmental concerns, stringent regulations, and fluctuations in raw material prices have posed hurdles for the industry china billions tio2. Despite these, Chinese manufacturers have demonstrated resilience through innovation and technological advancements, improving efficiency and reducing environmental impact.

china billions tio2. Despite these, Chinese manufacturers have demonstrated resilience through innovation and technological advancements, improving efficiency and reducing environmental impact.Quality Titanium Dioxide Suppliers:

Titanium dioxide is predominantly used as a pigment in products such as paints, coatings, plastics, food, cosmetics, and paper. The ability of TiO2 to scatter light and provide a white color makes it an essential ingredient in achieving high-quality finishes in these applications. However, the production of titanium dioxide can be complex and costly, given that it involves raw materials such as ilmenite and rutile, as well as advanced processing technologies. Manufacturers are continuously striving to optimize costs without compromising quality, making the search for affordable suppliers a top priority for many businesses.

LITHOPONE

What is an exposure route?

Titanium dioxide in food is used in a variety of products as a color enhancer. The most common foods containing titanium dioxide include:

3. The calcined product obtained by the ordinary zinc bismuth method is slurried into a slurry, which is sequentially treated with sodium silicate, aluminum sulfate or sodium aluminate and a surfactant, and then filtered, washed, dried and pulverized.

Following the EU’s ban on E171, the FDA told the Guardian that, based on current evidence, titanium dioxide as a food additive is safe. “The available safety studies do not demonstrate safety concerns connected to the use of titanium dioxide as a color additive.”

Some consumer advocacy groups and health agencies — particularly, those at the Environmental Working Group — have been pushing federal officers at the Food and Drug Administration (FDA) to reconsider their existing rules on the additive, which is commonly found in processed snacks and sweets.

Tioxide process. This process is similar to that used to produce fumed silicas. Ultra-low particle size titanium dioxide (15-35 nm) is obtained for use as photocatalyst or UV absorber (for instance in sun protective creams).

Cosmetics

In a small study published in the European Journal of Nutrition in 2020, researchers examined the effects of several food additives, including titanium dioxide, along with artificial sweeteners and cleaning products by testing the fecal samples of 13 people. Titanium dioxide was among the samples that “induced significant shifts in microbiome community structure.” The growth of the bacterium species belonging to C. leptum, which has been shown to decrease in patients with inflammatory bowel disease, “significantly decreased in the presence of … titanium dioxide” among other additives and sweeteners tested.

inner wall coating factories. Many factories are now producing coatings that are low in volatile organic compounds (VOCs) and free from harmful chemicals. These environmentally friendly coatings not only benefit the health of occupants but also contribute to a more sustainable future.

inner wall coating factories. Many factories are now producing coatings that are low in volatile organic compounds (VOCs) and free from harmful chemicals. These environmentally friendly coatings not only benefit the health of occupants but also contribute to a more sustainable future.