high quality thick slurry pump suppliers

Latest articles

If you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

high quality thick slurry pump suppliers...

high quality thick slurry pump suppliers 【high quality thick slurry pump suppliers】

Read MoreMill sump

high quality thick slurry pump suppliers...

high quality thick slurry pump suppliers 【high quality thick slurry pump suppliers】

Read MoreApplications

high quality thick slurry pump suppliers...

high quality thick slurry pump suppliers 【high quality thick slurry pump suppliers】

Read MoreThere are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

high quality thick slurry pump suppliers...

high quality thick slurry pump suppliers 【high quality thick slurry pump suppliers】

Read MoreTo reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

high quality thick slurry pump suppliers...

high quality thick slurry pump suppliers 【high quality thick slurry pump suppliers】

Read MorePump selection for FGD

high quality thick slurry pump suppliers...

high quality thick slurry pump suppliers 【high quality thick slurry pump suppliers】

Read MoreHow to Succeed in Slurry Pumping?

high quality thick slurry pump suppliers...

high quality thick slurry pump suppliers 【high quality thick slurry pump suppliers】

Read MoreAnother important target=_blank title=Part of the Slurry Pump>part of the slurry pump is its casing, which bears all the pressure. The slurry pump casing should have a large clearance between the impeller and the diversion angle to reduce wear and prevent large solid particles from getting stuck. Due to the extra space, there is more recirculation in the slurry pump casing under various operating conditions. Again, this accelerates wear compared to typical pumps.

high quality thick slurry pump suppliers...

high quality thick slurry pump suppliers 【high quality thick slurry pump suppliers】

Read MorePumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

high quality thick slurry pump suppliers...

high quality thick slurry pump suppliers 【high quality thick slurry pump suppliers】

Read MoreCarbon transfer

high quality thick slurry pump suppliers...

high quality thick slurry pump suppliers 【high quality thick slurry pump suppliers】

Read More

Popular articles

- The first major requirement for >slurry pumps is to provide adequate service life. The erosive and corrosive effects of slurries, such as the impact of high velocity flow of liquid/solid mixtures, can be really challenging. In many applications, some of the solids in the mixture are larger than the particles normally specified; therefore, the pump should be able to pass through them without causing any damage or operational problems.

- Slurry Pump

- Slurry Pump

- Materials of Construction

- If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

- Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

Latest articles

-

Dredge Pump

-

>Dredge Pump

-

For certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

-

In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

-

Slurry Pump

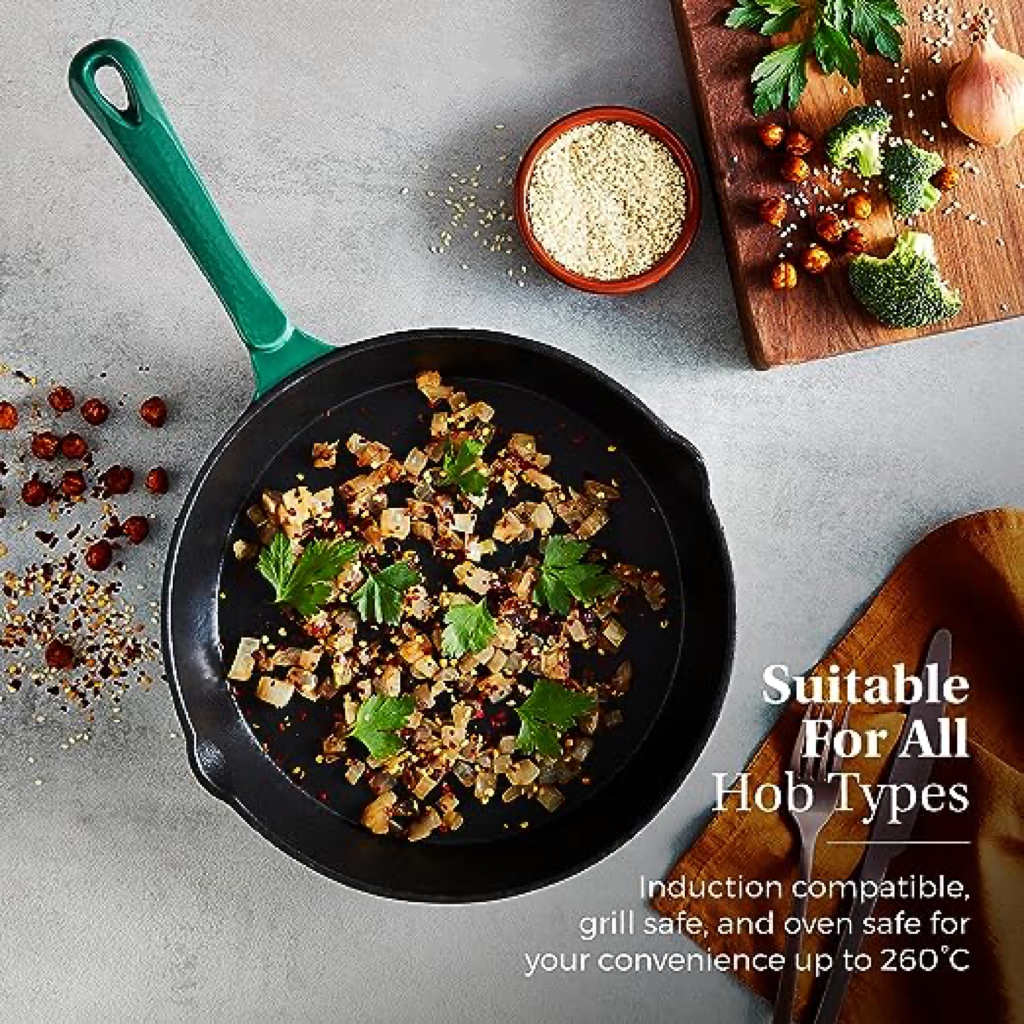

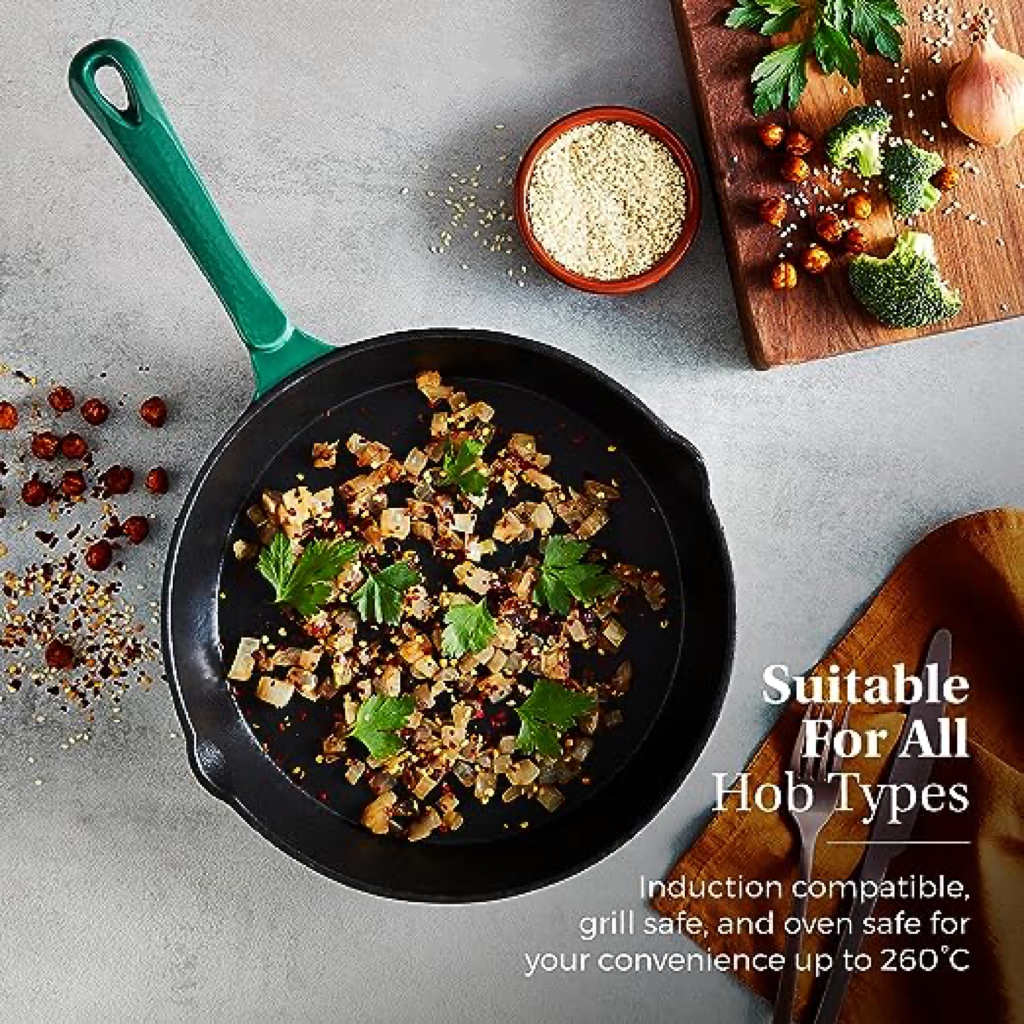

The occasional pouring spouts also make skillets ideal for reductions as you can easily pour it out without manually scooping. Not forgetting that skillets are often the outdoor enthusiasts’ favourite companion thanks to its almost indestructible and robust nature.

Because the pan is made of stainless steel, it may be thinner and lighter. It takes less time to reach the necessary cooking temperature.

French skillets also come in different sizes, but they are typically much smaller, ranging from 8 to 12 inches.

It can be used in cooking at high temperatures.

It doesn't contain any PFOAs or PTFEs, making it a healthier alternative It doesn't contain any PFOAs or PTFEs, making it a healthier alternative

It doesn't contain any PFOAs or PTFEs, making it a healthier alternative It doesn't contain any PFOAs or PTFEs, making it a healthier alternative enamel pots and pans for sale.

enamel pots and pans for sale.Material World

The handles are designed for comfort and stability, making it easy to handle even the heaviest pots The handles are designed for comfort and stability, making it easy to handle even the heaviest pots

The handles are designed for comfort and stability, making it easy to handle even the heaviest pots The handles are designed for comfort and stability, making it easy to handle even the heaviest pots enamel cast iron pot set.

enamel cast iron pot set.Aside from being available in a range of different colors, the main advantage of enameled cast iron over unfinished cast iron is that it’s much less likely to rust, and is also relatively easy to clean and maintain. And while these pans are more of an investment than mass-market unfinished cast iron cookware, they offer invaluable convenience and elegance that’ll last for several lifetimes.