high quality twin casing slurry pump manufacturers

Latest articles

Choosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

high quality twin casing slurry pump manufacturers...

high quality twin casing slurry pump manufacturers 【high quality twin casing slurry pump manufacturers】

Read MoreSlurry Pump Impeller Size

high quality twin casing slurry pump manufacturers...

high quality twin casing slurry pump manufacturers 【high quality twin casing slurry pump manufacturers】

Read Moremethod and level of design reach international advanced level. The company has the first-class pump performance

high quality twin casing slurry pump manufacturers...

high quality twin casing slurry pump manufacturers 【high quality twin casing slurry pump manufacturers】

Read MoreConveying medium

high quality twin casing slurry pump manufacturers...

high quality twin casing slurry pump manufacturers 【high quality twin casing slurry pump manufacturers】

Read More2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

high quality twin casing slurry pump manufacturers...

high quality twin casing slurry pump manufacturers 【high quality twin casing slurry pump manufacturers】

Read MoreTypically, slurries are.

high quality twin casing slurry pump manufacturers...

high quality twin casing slurry pump manufacturers 【high quality twin casing slurry pump manufacturers】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

high quality twin casing slurry pump manufacturers...

high quality twin casing slurry pump manufacturers 【high quality twin casing slurry pump manufacturers】

Read MoreDetermine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

high quality twin casing slurry pump manufacturers...

high quality twin casing slurry pump manufacturers 【high quality twin casing slurry pump manufacturers】

Read MoreWith the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

high quality twin casing slurry pump manufacturers...

high quality twin casing slurry pump manufacturers 【high quality twin casing slurry pump manufacturers】

Read MoreAs wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

high quality twin casing slurry pump manufacturers...

high quality twin casing slurry pump manufacturers 【high quality twin casing slurry pump manufacturers】

Read More

Popular articles

- Pump selection for FGD

- Submersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

- The Company Adopts Advanced Computer Aided Engineering Software

- The slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

- Determine the operating parameters of the pump.

- Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

Latest articles

-

Dredge Pump

-

The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

-

High head (i.e. the height to which the pump can move the liquid)

-

Auxiliary equipment

-

What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

Links

- Terry cloth waffle robes have a lightweight yet cozy nature, making them perfect for year-round wear. They're ideal for post-shower freshness, a leisurely morning ritual, or as a comforting wrap after a long day. The breathable waffle weave ensures that they are neither too hot nor too cold, allowing for a comfortable wear in varying temperatures.

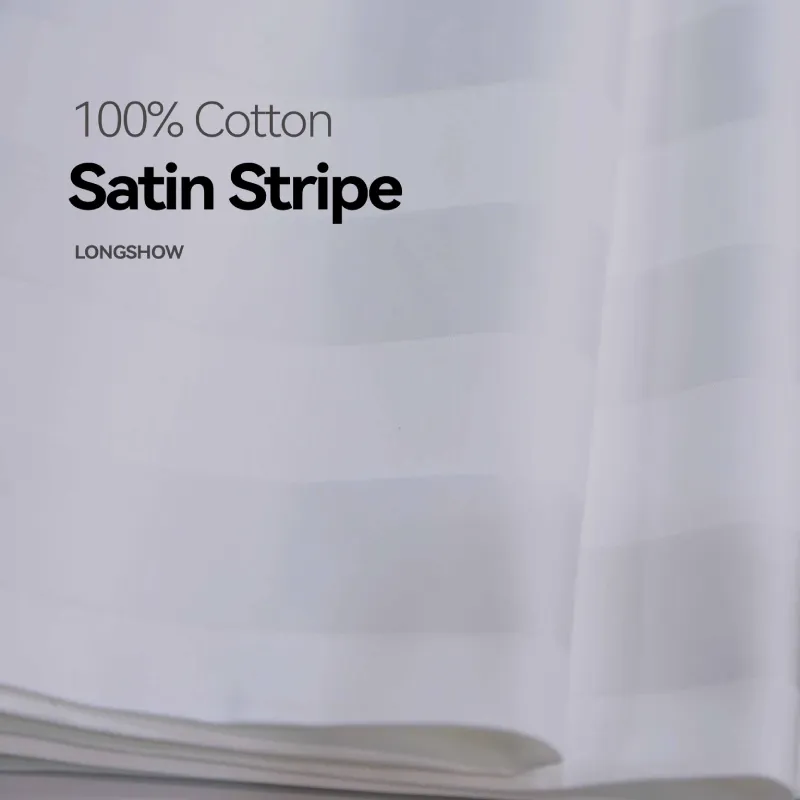

See ourbest sateen sheets.

wholesale beddings com. As a wholesale retailer, we're able to offer our products at significantly lower prices than retail stores. This means that you can stock up on all your bedding needs without breaking the bank. And with our bulk ordering options, you can save even more money by purchasing larger quantities of products at once.

wholesale beddings com. As a wholesale retailer, we're able to offer our products at significantly lower prices than retail stores. This means that you can stock up on all your bedding needs without breaking the bank. And with our bulk ordering options, you can save even more money by purchasing larger quantities of products at once. microfiber material for bedding. The material is machine washable and dries quickly, making it a convenient option for busy households or commercial settings. Microfiber bedding is also resistant to shrinking and wrinkling, so you can enjoy a smooth and neat bed without the hassle of ironing or steaming.

microfiber material for bedding. The material is machine washable and dries quickly, making it a convenient option for busy households or commercial settings. Microfiber bedding is also resistant to shrinking and wrinkling, so you can enjoy a smooth and neat bed without the hassle of ironing or steaming.Furthermore, we ensure that the cleanliness of our hotel bedding is of utmost importance. We follow rigorous cleaning protocols, including frequent washing, sanitization, and the use of high-quality detergents to maintain freshness and hygiene standards.

The waffle pattern adds an extra layer of resilience, enhancing the fabric's strength and resistance to wear and tear The waffle pattern adds an extra layer of resilience, enhancing the fabric's strength and resistance to wear and tear

The waffle pattern adds an extra layer of resilience, enhancing the fabric's strength and resistance to wear and tear The waffle pattern adds an extra layer of resilience, enhancing the fabric's strength and resistance to wear and tear terry cloth waffle robe.

terry cloth waffle robe.

Duvet covers are always equipped with a closure mechanism, such as buttons or zippers. Some are available with various ornamental decorations that add elegance and texture to them, such as embroidery, ribbons, or buttons, while others are plain. Duvet covers with pleats, ruching, and flocking are examples of various decorations that may be seen on high-quality bedding. Similarly, pleating is a form of fold that is created by folding fabric over itself while ruching is a procedure created by gathering little ripples in the fabric together. Flocking is the deposit of microscopic particles on the surface of a cloth.

Coverlet

A coverlet is a bedcovering with sides that hang down a few inches past the box spring, but don’t touch the floor. A coverlet can be tucked in or left untucked if edged with decorative trim. Luxury coverlets can be layered directly over a flat sheet or over a blanket. It may sometimes resemble a quilt, but unlike a quilt, which is comprised of several layers, a coverlet is just one layer of fabric woven in such a way that mimics the quilting technique.

This temperature regulating feature, coupled with their buttery smoothness, promotes a comfortable and undisturbed sleep throughout the night This temperature regulating feature, coupled with their buttery smoothness, promotes a comfortable and undisturbed sleep throughout the night

This temperature regulating feature, coupled with their buttery smoothness, promotes a comfortable and undisturbed sleep throughout the night This temperature regulating feature, coupled with their buttery smoothness, promotes a comfortable and undisturbed sleep throughout the night bed sheets 1800 thread count.

bed sheets 1800 thread count. The elasticated corners make it simple to tuck the sheet under the mattress, ensuring a neat and tidy appearance The elasticated corners make it simple to tuck the sheet under the mattress, ensuring a neat and tidy appearance

The elasticated corners make it simple to tuck the sheet under the mattress, ensuring a neat and tidy appearance The elasticated corners make it simple to tuck the sheet under the mattress, ensuring a neat and tidy appearance bedsheet with elastic all around. When it's time to change the sheets, simply pull the corners gently and the sheet will come off easily, saving you time and effort.

bedsheet with elastic all around. When it's time to change the sheets, simply pull the corners gently and the sheet will come off easily, saving you time and effort.