china warman ah slurry pump factories

Latest articles

With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

china warman ah slurry pump factories...

china warman ah slurry pump factories 【china warman ah slurry pump factories】

Read MoreWhen pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

china warman ah slurry pump factories...

china warman ah slurry pump factories 【china warman ah slurry pump factories】

Read MoreHow does a dredge pump work?

china warman ah slurry pump factories...

china warman ah slurry pump factories 【china warman ah slurry pump factories】

Read MoreTypical Applications of slurry pump

china warman ah slurry pump factories...

china warman ah slurry pump factories 【china warman ah slurry pump factories】

Read MoreSelecting a dredge pump

china warman ah slurry pump factories...

china warman ah slurry pump factories 【china warman ah slurry pump factories】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

china warman ah slurry pump factories...

china warman ah slurry pump factories 【china warman ah slurry pump factories】

Read MoreThe slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

china warman ah slurry pump factories...

china warman ah slurry pump factories 【china warman ah slurry pump factories】

Read MoreThe most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

china warman ah slurry pump factories...

china warman ah slurry pump factories 【china warman ah slurry pump factories】

Read MoreSelecting a dredge pump

china warman ah slurry pump factories...

china warman ah slurry pump factories 【china warman ah slurry pump factories】

Read More>Dredge Pump

china warman ah slurry pump factories...

china warman ah slurry pump factories 【china warman ah slurry pump factories】

Read More

Popular articles

- Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High

- target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

- Slurry Pump Selection

- Choosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

- How to Succeed in Slurry Pumping?

- Consider the impeller. Slurry pumps must have thicker vanes than water pumps to prevent wear. Due to the increased thickness, there will be fewer vanes, otherwise the passages will be too narrow and will affect the performance of the pump. The impeller should have a large enough passage so that the largest solid particles can pass through without clogging.

Latest articles

-

Compared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

-

Slurry Pump

-

Slurry Pump

-

AIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

-

Slurry Pump

-

Is the discharge configuration suitable for abrasive slurries?

Links

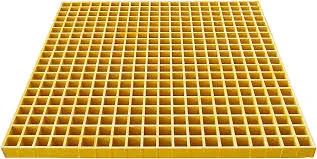

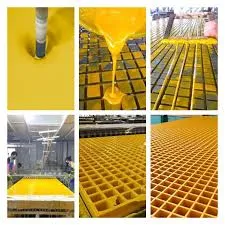

- Pultruded Grating: Produced through an assembling process from products generated by a pultrusion machine. Fibers, resin, pigments, and other additives are mixed in a vat and then pulled through a mold to form strong and rigid profiles.

- Lastly, the Bosch 11225VSR rounds out our list. It features a variable-speed control, allowing users to tailor the impact rate to the specific job, increasing efficiency. Its Constant Response Circuitry maintains speed under load, ensuring consistent performance. The anti-vibration system and soft-grip handles make this jack hammer comfortable to operate for extended periods.

- numerous architectural uses.

- Understanding and Utilizing Flat Drill Bits A Comprehensive Guide

- Threaded rock button bits are an essential component in the realm of drilling and construction engineering. These specialized tools, designed with precision, play a pivotal role in the process of drilling through hard rock formations.

- The importance of large drill bits cannot be overstated

- Fiberglass storage tanks are an essential component in various industries due to their durability, versatility, and cost-effectiveness. These tanks are widely used to store a variety of liquids, including water, chemicals, oil, and fuel.

In scenarios where an IPv6 network needs to communicate with an IPv4 network, a tunneling tool is used to encapsulate IPv6 packets within IPv4 packets, allowing them to pass through the IPv4 network In scenarios where an IPv6 network needs to communicate with an IPv4 network, a tunneling tool is used to encapsulate IPv6 packets within IPv4 packets, allowing them to pass through the IPv4 network

In scenarios where an IPv6 network needs to communicate with an IPv4 network, a tunneling tool is used to encapsulate IPv6 packets within IPv4 packets, allowing them to pass through the IPv4 network In scenarios where an IPv6 network needs to communicate with an IPv4 network, a tunneling tool is used to encapsulate IPv6 packets within IPv4 packets, allowing them to pass through the IPv4 network tunneling tool.

tunneling tool.

Lightweight Compared to other insulation materials, fiberglass is much lighter, making it easier to handle and transport Lightweight Compared to other insulation materials, fiberglass is much lighter, making it easier to handle and transport

Lightweight Compared to other insulation materials, fiberglass is much lighter, making it easier to handle and transport Lightweight Compared to other insulation materials, fiberglass is much lighter, making it easier to handle and transport fiberglass insulation tank. This is particularly beneficial for applications where space is limited or where weight is a concern.

fiberglass insulation tank. This is particularly beneficial for applications where space is limited or where weight is a concern.

“It is of great significance to establish a joint laboratory of composite materials with Sinochem International. The two sides will jointly promote technology development, results transformation and industrial application in related fields such as carbon fiber and solidified resins. We also will explore the collaborative innovation model of the technology joint research of a scientific research institute and an industrial group.”