china slurry pump metal lined parts manufacturer

Latest articles

Selecting And Operating A Slurry Pump

china slurry pump metal lined parts manufacturer...

china slurry pump metal lined parts manufacturer 【china slurry pump metal lined parts manufacturer】

Read MoreSelecting a dredge pump

china slurry pump metal lined parts manufacturer...

china slurry pump metal lined parts manufacturer 【china slurry pump metal lined parts manufacturer】

Read MoreStep 4

china slurry pump metal lined parts manufacturer...

china slurry pump metal lined parts manufacturer 【china slurry pump metal lined parts manufacturer】

Read MoreThere are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

china slurry pump metal lined parts manufacturer...

china slurry pump metal lined parts manufacturer 【china slurry pump metal lined parts manufacturer】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

china slurry pump metal lined parts manufacturer...

china slurry pump metal lined parts manufacturer 【china slurry pump metal lined parts manufacturer】

Read MoreReduced inventory

china slurry pump metal lined parts manufacturer...

china slurry pump metal lined parts manufacturer 【china slurry pump metal lined parts manufacturer】

Read MoreAgain, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

china slurry pump metal lined parts manufacturer...

china slurry pump metal lined parts manufacturer 【china slurry pump metal lined parts manufacturer】

Read MorePumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

china slurry pump metal lined parts manufacturer...

china slurry pump metal lined parts manufacturer 【china slurry pump metal lined parts manufacturer】

Read Moretarget=_blank>Slurry Pump

china slurry pump metal lined parts manufacturer...

china slurry pump metal lined parts manufacturer 【china slurry pump metal lined parts manufacturer】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

china slurry pump metal lined parts manufacturer...

china slurry pump metal lined parts manufacturer 【china slurry pump metal lined parts manufacturer】

Read More

Popular articles

- In this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

- Advantages of rubber

- - Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

- Again, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

- >Dredge Pump

- The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

Latest articles

-

Types of slurry pumps

-

Slurry Pump

-

Mill sump

-

Slurry pump design

-

Advantages of rubber

-

A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

In recent years, the demand for auto sewing machines has surged significantly, driven by advancements in technology and the growing interest in DIY projects, fashion design, and home textile industries. The convenience and efficiency offered by these machines have made them essential tools for both amateur and professional sewers alike. However, as the market expands, potential buyers often find themselves asking the crucial question what influences the price of auto sewing machines?

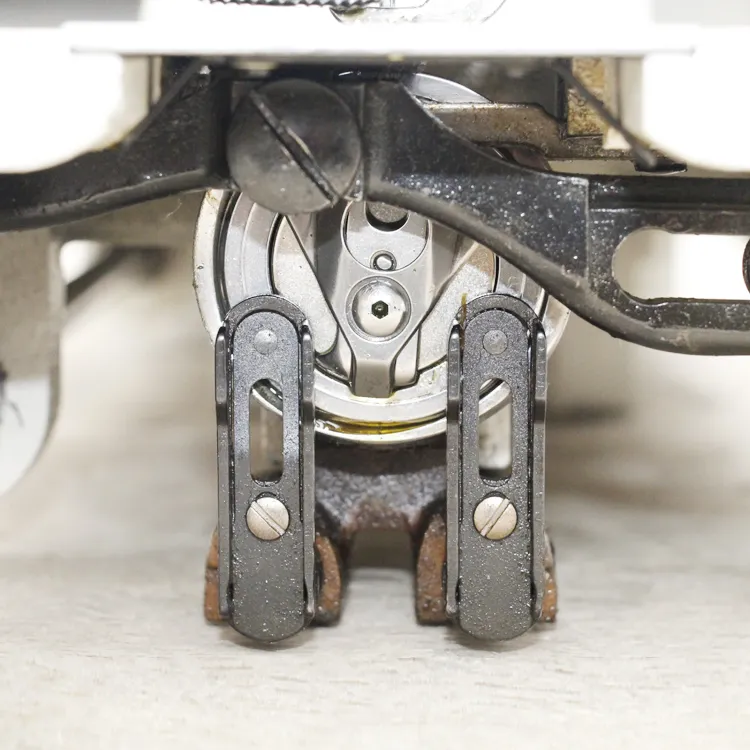

The key components of a leather stitching machine include a robust motor, a walking foot mechanism, and specialized needles. The walking foot is crucial as it helps to feed multiple layers of leather evenly, preventing slippage during sewing. This is particularly important when working with thicker leather, which can be challenging to handle manually.

Conclusion

2. Creating Stretch Seams