high quality horizontal froth pump manufacturer

Latest articles

The company uses advanced computer assistant engineering software to design products and technology, which makes our

high quality horizontal froth pump manufacturer...

high quality horizontal froth pump manufacturer 【high quality horizontal froth pump manufacturer】

Read MoreSubmersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

high quality horizontal froth pump manufacturer...

high quality horizontal froth pump manufacturer 【high quality horizontal froth pump manufacturer】

Read Morereduce the discharge pressure of the pump to the lowest possible point, and.

high quality horizontal froth pump manufacturer...

high quality horizontal froth pump manufacturer 【high quality horizontal froth pump manufacturer】

Read MoreLarger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

high quality horizontal froth pump manufacturer...

high quality horizontal froth pump manufacturer 【high quality horizontal froth pump manufacturer】

Read MoreWhat we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

high quality horizontal froth pump manufacturer...

high quality horizontal froth pump manufacturer 【high quality horizontal froth pump manufacturer】

Read MoreSlurry Pump

high quality horizontal froth pump manufacturer...

high quality horizontal froth pump manufacturer 【high quality horizontal froth pump manufacturer】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

high quality horizontal froth pump manufacturer...

high quality horizontal froth pump manufacturer 【high quality horizontal froth pump manufacturer】

Read MoreAnother way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

high quality horizontal froth pump manufacturer...

high quality horizontal froth pump manufacturer 【high quality horizontal froth pump manufacturer】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

high quality horizontal froth pump manufacturer...

high quality horizontal froth pump manufacturer 【high quality horizontal froth pump manufacturer】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

high quality horizontal froth pump manufacturer...

high quality horizontal froth pump manufacturer 【high quality horizontal froth pump manufacturer】

Read More

Popular articles

- The slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

- Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

- Longer maintenance intervals

- Expertise and experience

- >Dredge pumps are a special category of pumps used in the dredging process. Dredging is the process of transporting submerged sediments (usually sand, gravel or rock) from one area to another. Dredging takes place in the shallow waters of lakes, rivers or seas for land reclamation, dredging, flood control, new harbours or expansion of existing harbours. The various industries that use dredge pumps are therefore the construction industry, mining, the coal industry and the oil and gas industry.

- Corrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

Latest articles

-

How does a dredge pump work?

-

What style of pump is suitable?

-

What is the optimum seal arrangement for the application?

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

It is important that the pump you choose has components that will not wear out from abrasive slurries.

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

Links

Why Choose Manual Leather Stitching Machines?

In the world of sewing, the tools you choose can significantly impact the quality and efficiency of your work. Among these tools, the double needle walking foot sewing machine stands out as an essential instrument, especially for those involved in heavy fabrics or intricate quilting projects. This unique machine combines the functionality of a walking foot with the versatility of double needles, offering a plethora of benefits for sewers of all skill levels.

2. Enhanced Creativity With a dedicated workspace designed for upholstery, you are more likely to immerse yourself in your projects. A well-organized environment fosters creativity and encourages experimentation with designs and fabrics.

User Friendliness and Accessibility

4. Heavy-Duty Capability Most walking foot machines are designed to handle heavy-duty projects, featuring powerful motors and sturdy construction. This durability allows them to tackle thick leather without strain, making them ideal for professional leatherworkers and hobbyists alike.

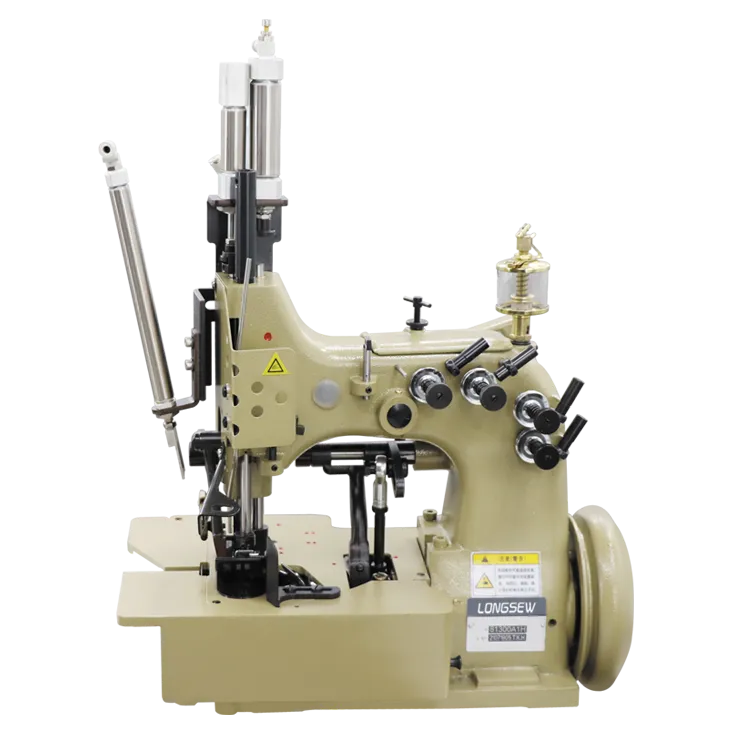

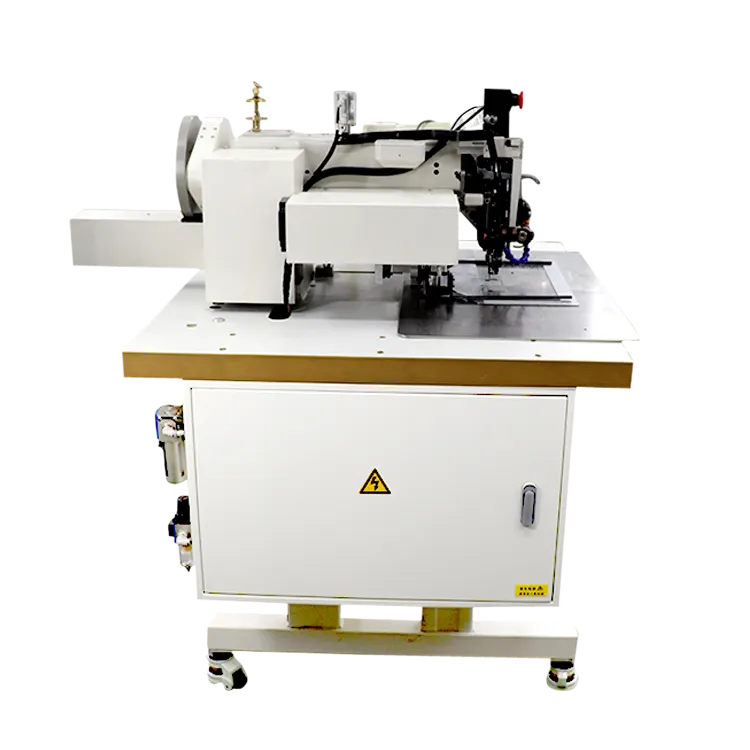

walking foot leather sewing machine

Sewing is an art form that combines creativity with technical skills, and one of the most innovative developments in the realm of sewing techniques is the double needle stretch stitch. This stitch offers both functional and aesthetic advantages, making it particularly popular for sewing stretchy fabrics, such as knits and activewear. In this article, we will explore what the double needle stretch stitch is, how it works, and its various applications in sewing projects.

- Efficiency These machines can sew through multiple layers of thick leather quickly and efficiently, saving you time on your projects.

One of the key features of heavy duty sewing machines is their ability to sew through multiple layers of thick fabric without compromising the quality of the stitches. They also come with a variety of specialized presser feet and needles to accommodate different types of heavy fabrics. Additionally, heavy duty sewing machines often have a larger workspace to accommodate bigger projects and more room for maneuvering bulky materials.

The price of portable bag closer machines can vary significantly, generally ranging from a few hundred to several thousand dollars. A basic model designed for small-scale operations may start at around $300 to $500. These machines usually have manual settings and are suitable for specific types of bags. On the other hand, more advanced and automated models can exceed $2,000 or even $5,000, depending on their features and capabilities.

3. Janome Horizon Memory Craft 9450QCP This high-end model is designed for serious quilters and sewists. It features an extensive 350 built-in stitches, precise stitching controls, and an impressive working space, enabling you to handle large projects with ease.

Hi-speed lockstitch sewing machines come equipped with numerous features designed to enhance usability and efficiency. Some standout features include

4. Cost-Effectiveness By reducing the need for additional finishing processes, manufacturers can save on production costs, thereby increasing their overall efficiency and profitability.

One of the key factors in using a handheld sewing machine on thick fabrics is the choice of needle and thread. For thick materials, a heavier needle is necessary; a denim or universal needle is typically recommended as they are built to penetrate multiple layers of fabric. Likewise, a strong thread, such as polyester or upholstery thread, ensures that the seams remain intact under stress. Investing in the right supplies upfront can make a significant difference in the outcome of your sewing projects.

handheld sewing machine thick fabric

Automatic button sewing machines are not limited to traditional clothing applications. They can also be utilized in creating custom crafts, upholstery work, and even in the production of accessories. With the ability to handle various button sizes and styles, from basic plastic to decorative metal buttons, these machines can cater to a wide range of projects.

In industrial settings, these machines are celebrated for their efficiency. They can operate at high speeds, which significantly boosts productivity on assembly lines. The availability of various presser feet and attachments allows for specialized tasks such as zigzag stitching, blind hemming, and quilting.

single needle lockstitch machine

II. Choosing the Right Heavy Duty Sewing Machine

1. Powerful Motor A machine with a stronger motor is essential for sewing heavy fabrics. A motor with at least 1.0 amp power rating is generally recommended for working with materials like canvas.

Benefits of Using Heavy-Duty Denim Thread

1. Versatility One of the primary advantages of heavy-duty sewing machines is their versatility. They can sew through various materials, making them ideal for a wide range of projects. Whether you are working on fashion design, upholstery, or crafting sturdy outdoor gear, a heavy-duty machine can tackle it all with ease.

Additionally, these machines often come with multi-needle capabilities. This feature allows for the use of different thread colors and types without the need for constant rethreading, significantly reducing production time. High-speed operation is another hallmark of industrial zig zag machines, with some capable of producing thousands of stitches per minute, which drastically increases output.

Speed

1. Type of Overlocker There are several types of overlockers on the market, each designed for specific tasks. Common types include 2-thread, 3-thread, and 4-thread overlockers. The more threads used, the more robust the stitching. Assess your production needs to determine the right type.

Key Features of Domestic Lockstitch Sewing Machines

Industrial Sewing Machines: Given their continuous operation, these machines demand regular and thorough maintenance. However, due to their robust build, they might require less frequent repairs if appropriately maintained.

In conclusion, the 2% needle walking foot sewing machine represents a perfect blend of technology and craftsmanship, enhancing the sewing experience for individuals at all skill levels. With its unique walking foot mechanism, it provides sewists with the reliability and precision needed to tackle various projects, pushing the boundaries of creativity. Whether you are a hobbyist looking to explore new sewing techniques or a professional needing a dependable tool for complex garments, investing in a 2% needle walking foot sewing machine is likely to pay dividends in the form of satisfying results and limitless possibilities. As sewing continues to evolve, this machine remains a steadfast companion, empowering creativity and innovation in the world of textiles.

1. Tension Settings Adjusting your sewing machine's tension settings may be necessary when using heavy-duty thread. A loose tension can cause loops and poor seam quality, while too much tension can break the thread. Perform a test stitch on a scrap piece of canvas to find the right balance.

2. Enhanced Aesthetic Appeal Thick threads add a visual element to leather projects. The pronounced stitches create a statement on the surface of the leather, enhancing the overall design. Contrast stitching, where the thread color differs from the leather, becomes especially pronounced when using thick thread, allowing artisans to experiment with colors and design patterns that elevate the aesthetic value of their creations.

thick thread for sewing leather

5. Ease of Adjustment Many industrial sergers come equipped with advanced tension control and stitch length settings, allowing operators to quickly adjust their settings based on fabric type and desired stitch characteristics.

The Versatility and Advantages of Raised Bed Sewing Machines

3. Tents and Canvas Products: Outdoor products like tents, sun shades and backpacks often use sturdy canvas or similar fabrics. extra heavy duty sewing machines can effectively join these materials for waterproof and long-lasting seams.

Choosing the Right Sewing Machine for Boat Upholstery

5. Embroidery Needles Designed for free-motion embroidery and decorative stitching, these needles feature a larger eye to accommodate thicker embroidery threads.

In conclusion, CNC programmable sewing machines are revolutionizing the textile and garment industry by providing unmatched precision, efficiency, and adaptability. As manufacturers continue to seek innovative ways to improve production processes while meeting consumer demands for sustainable and unique products, these advanced machines are likely to play an increasingly pivotal role. The marriage of technology and craftsmanship in sewing not only enhances productivity but also paves the way for a more sustainable and capable future in fashion manufacturing.

Selecting the right needle and thread is critical in heavy-duty sewing. For thicker fabrics, you'll want to use a needle designed for heavy materials, such as a jeans needle or a leather needle. These needles are stronger and have a larger eye to accommodate thicker threads.

heavy duty sewing

While double needle sewing machines offer numerous benefits, they can present a bit of a learning curve, especially for those new to sewing. The setup may require some practice, particularly when it comes to threading the machine and managing two threads simultaneously. However, many manufacturers provide comprehensive manuals and resources to help users navigate the initial challenges. Additionally, once familiar with the machine, users often find that the rewards far outweigh the initial hurdles.

Flat bed sewing machines are a fundamental tool in the world of sewing and textile production, known for their simplicity and versatility. This article explores what a flat bed sewing machine is, its key applications, and the benefits it offers to both amateur and professional sewers.

1. Heavy-duty Construction The machine must be built to withstand the stress of sewing thick woven materials. A robust frame and quality components are crucial for longevity and reliability.

woven sack bag sewing machine

One of the standout features of handheld leather sewing machines is their portability. Whether you're crafting in your living room, working on a project at a friend's house, or even taking your materials to a workshop, these machines are easy to transport. Their mobile nature encourages creativity on the go, allowing crafters to seize inspiration wherever they find it.