standard submersible slurry pump manufacturers

Latest articles

Slurry pump design

standard submersible slurry pump manufacturers...

standard submersible slurry pump manufacturers 【standard submersible slurry pump manufacturers】

Read MoreNon-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

standard submersible slurry pump manufacturers...

standard submersible slurry pump manufacturers 【standard submersible slurry pump manufacturers】

Read MoreAll manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

standard submersible slurry pump manufacturers...

standard submersible slurry pump manufacturers 【standard submersible slurry pump manufacturers】

Read MoreUsing rubber as a wear lining material means

standard submersible slurry pump manufacturers...

standard submersible slurry pump manufacturers 【standard submersible slurry pump manufacturers】

Read MoreIf a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

standard submersible slurry pump manufacturers...

standard submersible slurry pump manufacturers 【standard submersible slurry pump manufacturers】

Read MoreIn this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

standard submersible slurry pump manufacturers...

standard submersible slurry pump manufacturers 【standard submersible slurry pump manufacturers】

Read MorePumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal target=_blank title=Slurry Pump>slurry pump. Let's talk about how slurry pumps differ from standard pumps and how to narrow your choices.

standard submersible slurry pump manufacturers...

standard submersible slurry pump manufacturers 【standard submersible slurry pump manufacturers】

Read MoreSlurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

standard submersible slurry pump manufacturers...

standard submersible slurry pump manufacturers 【standard submersible slurry pump manufacturers】

Read More>Dredge pumps are a special category of pumps used in the dredging process. Dredging is the process of transporting submerged sediments (usually sand, gravel or rock) from one area to another. Dredging takes place in the shallow waters of lakes, rivers or seas for land reclamation, dredging, flood control, new harbours or expansion of existing harbours. The various industries that use dredge pumps are therefore the construction industry, mining, the coal industry and the oil and gas industry.

standard submersible slurry pump manufacturers...

standard submersible slurry pump manufacturers 【standard submersible slurry pump manufacturers】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our

standard submersible slurry pump manufacturers...

standard submersible slurry pump manufacturers 【standard submersible slurry pump manufacturers】

Read More

Popular articles

- AIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

- Pumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

- One problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

- The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

- - Low noise level - Operating underwater results in low noise or even silent operation.

- Slurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

Latest articles

Links

Maintaining a stainless steel box is a breeze. Its smooth surface is easy to clean and resist stains, allowing you to keep it looking new with minimal effort. Regular wiping with a damp cloth is typically all that’s needed to maintain its luster. This low-maintenance requirement is particularly appealing for individuals and businesses alike, freeing up time and resources that can be better spent elsewhere.

- 2. Casement windows These windows open and close like a door, with a hinged sash that swings outwards or inwards. They are available in a variety of styles, including awning, hopper, and picture windows.

- Steel vs Iron A Comparative Analysis of Strength

How Much Do Aluminum Profiles For Windows And Doors Cost?

- Door rollers for sliding doors are an essential component in ensuring smooth and efficient operation of sliding doors. These small but crucial devices play a significant role in allowing the door to glide effortlessly along its track, making it easier for users to open and close the door with minimal effort.

- In the realm of home and commercial improvement, sliding screen rollers have emerged as a versatile and practical solution for various applications. These rollers, often made of high-quality materials such as aluminum or steel, are designed to provide smooth and effortless movement of screens, doors, and windows.

- Beyond replacements, Sliding Door Roller Replacement Inc offers maintenance tips to prolong the life of your newly serviced doors. This includes regular cleaning of tracks to prevent buildup that could hinder smooth operation, lubrication of moving parts to reduce wear and tear, and periodic checks for any signs of wear that could indicate the need for adjustments or further servicing.

Sliding doors have become a popular choice for homeowners and businesses alike, providing an elegant way to save space while enhancing the aesthetic appeal of interiors. Whether it's a patio door leading to a garden or an interior door separating rooms, the functionality of these doors relies heavily on one crucial component sliding door runner wheels. This article will explore the importance of these wheels, their types, maintenance tips, and how to choose the right ones for your sliding doors.

- Door Weight Ensure that the wheels can support the weight of your door. Heavier doors typically require more substantial wheels, such as steel or heavy-duty nylon rollers.

wheels for sliding door track

Step 1 Remove the Screen Door

steel box lock. They come in a variety of sizes and designs to meet the specific needs of different users. Whether you need a small lock for a jewelry box or a larger lock for a storage unit, there is a steel box lock that will fit your requirements.

Since most of the material in your aluminum fence is made up of this abundant metal, you may be thinking, why is it so expensive in the first place? After all, isn’t most of it recycled aluminum anyway?

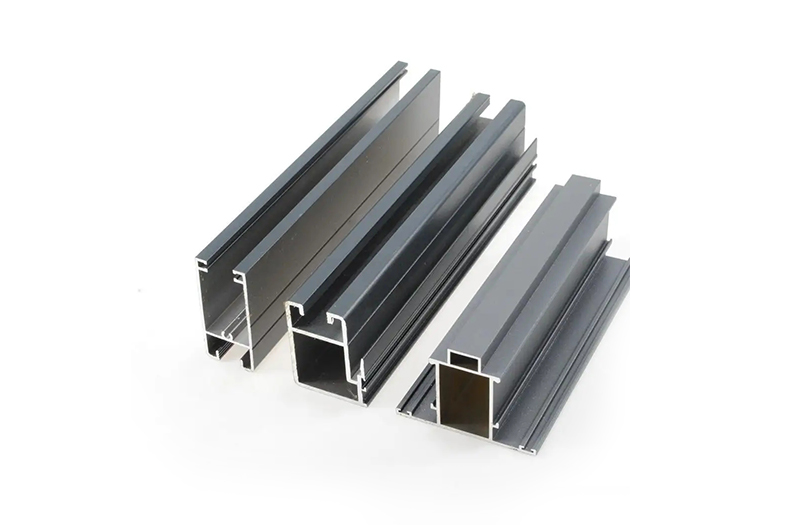

The applications of slimline aluminium profiles are extensive. In residential settings, they are commonly used for elegant window frames and sliding doors, enhancing natural light while offering unobstructed views. In commercial environments, these profiles serve as eye-catching display units and modular partition systems, enabling flexibility in space design.

One of the standout features of wrought iron is its workability. Skilled artisans can manipulate it into stunning shapes and intricate patterns, creating a unique blend of function and artistry. Decorative wrought iron pieces can be customized to reflect a variety of styles, including Gothic, Baroque, or even contemporary designs.

decorative iron gates. A well-designed gate can make a striking first impression on visitors and passersby, enhancing the overall aesthetic of the home or garden. They can also increase the value of a property, as potential buyers are often willing to pay a premium for a home with a beautiful and secure entrance.

They are used for structural purposes in different construction, architectural and industrial settings.

Steel and iron are two of the most commonly used metals in the world. They are both known for their strength and durability, making them essential materials in construction, manufacturing, and various other industries. But when it comes to determining which is stronger, steel or iron, the answer is not always straightforward.

As the technical content and the degree of mechanization of doors and windows are not high, most of them rely mostly on the manual operation of the installation workers, which requires the operators to have a good sense of product quality. It is important to strengthen the proficiency of the operators and their product awareness during the production process. High-quality aluminium windows should acquire the following qualities: fine processing, consistent angle (the main frame is usually 45 or 90 degrees), no obvious gaps during the splicing process, good sealing performance and smooth operation.

Aluminium Profiles Quality Test │ Raw Material

Sliding door rollers are typically located at the bottom of the door panel. These rollers allow the door to glide along the track, making it easy to open and close. Over time, dust and debris can accumulate in the track, or the rollers themselves may become worn, resulting in a door that sticks or will not slide properly.

5. Compliance with standard specifications