high quality casting slurry pump part manufacturers

Latest articles

Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High

high quality casting slurry pump part manufacturers...

high quality casting slurry pump part manufacturers 【high quality casting slurry pump part manufacturers】

Read MoreI hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

high quality casting slurry pump part manufacturers...

high quality casting slurry pump part manufacturers 【high quality casting slurry pump part manufacturers】

Read MoreSites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

high quality casting slurry pump part manufacturers...

high quality casting slurry pump part manufacturers 【high quality casting slurry pump part manufacturers】

Read MoreHydrostatic head - i.e. the height to which the slurry must be lifted in the piping system.

high quality casting slurry pump part manufacturers...

high quality casting slurry pump part manufacturers 【high quality casting slurry pump part manufacturers】

Read MoreUnderwater installation

high quality casting slurry pump part manufacturers...

high quality casting slurry pump part manufacturers 【high quality casting slurry pump part manufacturers】

Read MoreWhen slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

high quality casting slurry pump part manufacturers...

high quality casting slurry pump part manufacturers 【high quality casting slurry pump part manufacturers】

Read MoreSlurry pipe diameter.

high quality casting slurry pump part manufacturers...

high quality casting slurry pump part manufacturers 【high quality casting slurry pump part manufacturers】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality casting slurry pump part manufacturers...

high quality casting slurry pump part manufacturers 【high quality casting slurry pump part manufacturers】

Read MoreLifetime use

high quality casting slurry pump part manufacturers...

high quality casting slurry pump part manufacturers 【high quality casting slurry pump part manufacturers】

Read MoreWZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

high quality casting slurry pump part manufacturers...

high quality casting slurry pump part manufacturers 【high quality casting slurry pump part manufacturers】

Read More

Popular articles

- How to Succeed in Slurry Pumping?

- Slurry Pump

- >Vertical Slurry Pump

- Although the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

- The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

- Many types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

Latest articles

-

What is Heavy Duty Slurry Pump?

-

>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

-

Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

-

Slurry Pump

-

Dredge pumps are designed to transfer large quantities of fluids and solids.

-

Follow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

However, like any product, it is important to remember that while Flex Tape is highly effective for many applications, it may not be suitable for every situation. For example, for structural repairs or tasks that require significant strength, traditional methods such as welding or mechanical fasteners should be considered.

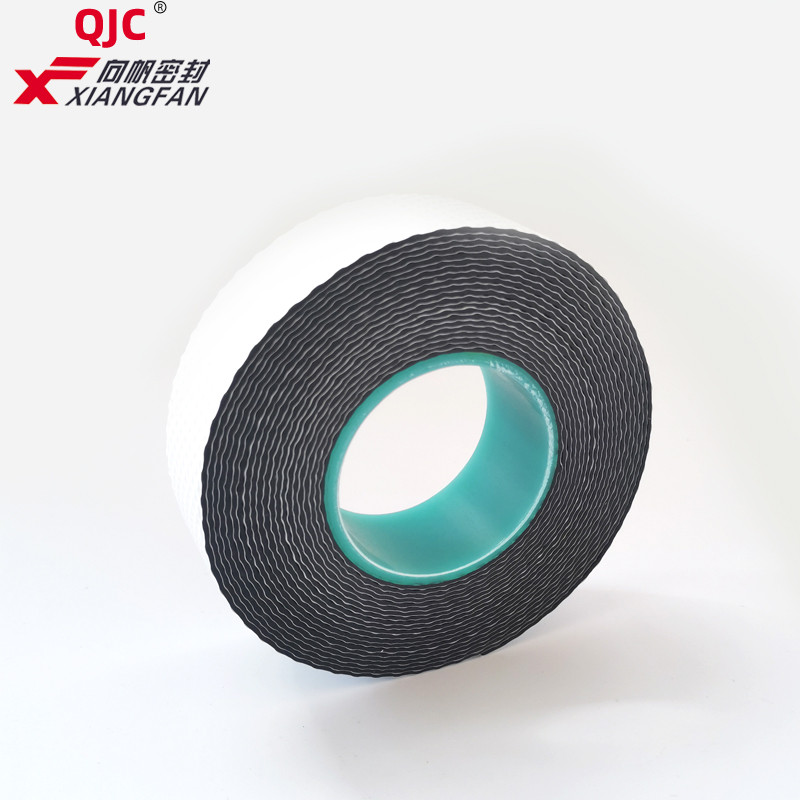

black cloth tape automotive.

LDPE Mosaic Tile Tape

Water-Activated

You can also find many more in-depth studies of what makes a good control box online. They’ll help you get a good idea of how to design component spacing, wireways and more. Next up, we’ll take a look at what some of the different types of control boxes look like and how they function.

Its flexibility also allows it to conform to uneven surfaces, ensuring a tight and secure fit every time Its flexibility also allows it to conform to uneven surfaces, ensuring a tight and secure fit every time

Its flexibility also allows it to conform to uneven surfaces, ensuring a tight and secure fit every time Its flexibility also allows it to conform to uneven surfaces, ensuring a tight and secure fit every time flex seal flex tape black 4 x 5.

flex seal flex tape black 4 x 5.

The Versatile Utility of Flex Tape A Comprehensive Look at Flex Tape White 4x5

The Importance of Flame Retardant Tapes in Safety and Versatility

Its self-adhesive property eliminates the mess and complexity associated with using separate adhesives, saving time and effort in the process Its self-adhesive property eliminates the mess and complexity associated with using separate adhesives, saving time and effort in the process

Its self-adhesive property eliminates the mess and complexity associated with using separate adhesives, saving time and effort in the process Its self-adhesive property eliminates the mess and complexity associated with using separate adhesives, saving time and effort in the process self bonding rubber tape.

self bonding rubber tape.Conclusion

Take the tape and cut it to your required length using scissors or a stanley knife

2. Durability Made to withstand extreme temperatures and harsh environments, self-fusing rubber tape maintains its effectiveness and integrity over time. Its resistance to abrasion, UV radiation, and chemical exposure ensures longevity, even in challenging conditions.