centrifugal slurry pump spares factories

Latest articles

Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

centrifugal slurry pump spares factories...

centrifugal slurry pump spares factories 【centrifugal slurry pump spares factories】

Read MoreSlurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

centrifugal slurry pump spares factories...

centrifugal slurry pump spares factories 【centrifugal slurry pump spares factories】

Read MoreSlurry Pump Considerations

centrifugal slurry pump spares factories...

centrifugal slurry pump spares factories 【centrifugal slurry pump spares factories】

Read MoreChoosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

centrifugal slurry pump spares factories...

centrifugal slurry pump spares factories 【centrifugal slurry pump spares factories】

Read MoreSlurry Pump

centrifugal slurry pump spares factories...

centrifugal slurry pump spares factories 【centrifugal slurry pump spares factories】

Read MoreSubmersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

centrifugal slurry pump spares factories...

centrifugal slurry pump spares factories 【centrifugal slurry pump spares factories】

Read MoreAier is pumping experts and offer some useful tips to maintain your >slurry pump.

centrifugal slurry pump spares factories...

centrifugal slurry pump spares factories 【centrifugal slurry pump spares factories】

Read More- Pumping the final product in a process

centrifugal slurry pump spares factories...

centrifugal slurry pump spares factories 【centrifugal slurry pump spares factories】

Read MoreAs described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

centrifugal slurry pump spares factories...

centrifugal slurry pump spares factories 【centrifugal slurry pump spares factories】

Read MoreDesire for higher efficiency than centrifugal pumps

centrifugal slurry pump spares factories...

centrifugal slurry pump spares factories 【centrifugal slurry pump spares factories】

Read More

Popular articles

- Applications

- The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

- Two types of slurry are found in these industries.

- 600WN to 1000WN dredge pumps are of double casings, single stage cantilevered centrifugal pumps. These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

- The terms 'flushing' and 'quench' often seem to be confused or misused when discussing seal support schemes for >slurry pumps. As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

- Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

Latest articles

-

3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

-

Sump drainage or washdown

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

-

Pumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal , slurry pump, . Lets talk about how slurry pumps differ from standard pumps and how to narrow your choices.

-

The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

-

What is 'slurry'?

Links

- - Healthcare Facilities Hospitals and clinics utilize these ceilings for ease of maintenance and hygiene control, as many tiles are washable.

In addition to thermal insulation, Micore 300 also excels in sound insulation. The mineral fiber construction effectively dampens sound transmission, making it an ideal choice for applications requiring privacy and noise control, such as offices, schools, and residential buildings. By employing Micore 300, architects and builders can create quieter, more conducive environments for work and living.

Environmental Considerations

Applications in Various Sectors

Ceiling T bars offer a multitude of benefits, making them a popular choice in both commercial and residential spaces

Mineral wool, also known as rock wool or stone wool, is an insulation material made from natural or recycled stone or basalt. The process involves melting the stones at high temperatures and then spinning them into fibers. These fibers are then processed into various forms, including batts, blankets, and boards. Mineral wool is highly regarded for its impressive thermal and acoustic insulation properties, as well as its resistance to fire and moisture.

Installing a metal drywall ceiling grid involves several key steps

metal drywall ceiling grid

In summary, laminated ceiling tiles represent a transformative solution in interior design, blending aesthetic appeal, functionality, and sustainability. Their variety of styles, ease of installation, sound insulation properties, and low maintenance make them an attractive choice for a wide array of applications. Embracing laminated ceiling tiles is not merely about changing a ceiling; it’s about enhancing the overall experience of a space, making it a vital consideration for anyone looking to refresh their environment. Whether for personal satisfaction or professional design projects, laminated ceiling tiles offer the perfect combination of style and substance.

In conclusion, ceiling grids serve as an essential element in contemporary construction and design, blending functionality with aesthetic value. Whether in commercial, educational, or residential settings, they not only enhance the visual appeal of a space but also provide practical benefits like accessibility and sound control. As construction trends evolve, ceiling grids are likely to remain a staple in creating versatile and functional interiors.

T-grid ceilings, also known as suspended ceilings or drop ceilings, are a vital component of many commercial buildings, including offices, schools, hospitals, and retail spaces. They provide various benefits, such as improved sound absorption, aesthetic enhancement, and ease of maintenance. One of the key features of T-grid ceilings is their ability to hide wiring, ducts, and other infrastructural elements, resulting in a cleaner and more polished appearance.

The advantages of using suspended ceiling access panels extend beyond mere functionality. They contribute positively to building design in several ways

Applications of Fibre Ceiling Sheets

Conclusion

Benefits of Fire Rated Ceiling Access Panels

Properly installed grid hangers ensure that the ceiling tiles maintain their position over time, preventing sagging or misalignment. This stability is essential, particularly in commercial spaces, where aesthetic uniformity enhances the professional appearance of the environment.

6. Install the Panel

In the event of a fire, these doors help to contain the spread of smoke and flames, allowing occupants more time to escape and giving emergency responders a better chance to control the situation. This characteristic is particularly essential in high-rise buildings, hospitals, and schools, where large numbers of people may be present during a fire emergency.

Installation costs can add another layer of expense. Hiring professional contractors may increase the total cost by $2 to $5 per square foot for labor, depending on the region and the contractor's experience. Therefore, the total cost of installing a drywall ceiling can range from $3 to $8 per square foot when combining materials and labor.

With time, better alternatives came up, but mineral fibre still topped the list because it's more affordable.

Benefits of Flush Mount Access Panels

Understanding Drywall Ceiling Hatches A Comprehensive Guide

1. Aesthetic Appeal The primary advantage of flush mount ceiling access panels is their ability to maintain the visual integrity of a space. They can be custom-finished to match the surrounding ceiling, making them virtually invisible. This feature is particularly important in settings where design elegance dictates the choice of materials and finishes.

Understanding the different types of mineral fiber can help make better choices for the unique needs of a space.

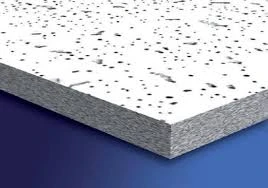

High quality Mineral Fiber Ceiling Tiles

The installation of perforated metal grid ceilings is relatively straightforward, making them a cost-effective choice for many projects. They are usually installed in a suspended ceiling system, which allows for easy access to utilities behind the ceiling. This accessibility is vital for maintenance and repairs, ensuring that building owners can address issues without significant disruption. Moreover, the durability of metal means that these ceilings can maintain their appearance and functionality over many years, providing long-term value to property owners.

The system typically consists of main beams, usually 12 feet long, that are installed parallel to each other, with cross tees that connect them perpendicularly at various intervals, forming a grid. The ceiling tiles can then rest on this grid, providing a clean, finished look.

Understanding Access Panel Ceiling Drywall Importance and Installation

As of 2023, the average cost of gypsum grid ceilings can vary widely. On a per-square-foot basis, installation costs often range from $2 to $6, depending on the factors outlined above. For a standard 10x10 foot room, total costs can range from $200 to $600, including materials and labor. It’s advisable to obtain multiple quotes from contractors to ensure a competitive price.

Overcoming the Limitations

Understanding T-Bar Ceiling Grid Systems

Conclusion

2. Fire Resistance Given their mineral composition, mineral fiber planks are inherently fire-resistant, complying with various safety standards. This quality is crucial for commercial buildings, where fire safety regulations are stringent. In case of a fire, these planks can help slow down the spread of flames, contributing to enhanced safety for occupants.

mineral fiber planks for ceiling

Another significant advantage is the ease of access they provide. In commercial settings, where maintenance is frequently required, having a discreet way to reach electrical wiring or plumbing can save time and reduce labor costs. Instead of dismantling segments of the ceiling, maintenance personnel can simply open the access panel, perform necessary checks, and close it back up, minimizing disruption to the ongoing operations of the facility.

gypsum ceiling access panel

Benefits of Vinyl Coated Gypsum Ceiling Tiles

1. Sound Absorption One of the primary advantages of acoustic mineral boards is their ability to absorb sound. These panels can significantly reduce reverberation time, which is the persistence of sound in a space after the original sound source has stopped. By absorbing excess sound, they help maintain a clear and intelligible acoustic environment, making spaces like classrooms, offices, and auditoriums more conducive to communication.

Gypsum ceiling panels are made from gypsum plaster encased in thick paper. This composition grants them attributes such as fire resistance, sound insulation, and ease of installation. Gypsum ceilings can be molded into various shapes and designs, making them suitable for diverse architectural styles. They can be painted, textured, or left plain, offering homeowners and designers great flexibility in achieving their desired look.

Maintaining these systems is also easy, as tiles can be replaced without having to dismantle the entire ceiling. If a tile becomes stained or damaged, it can simply be lifted out and replaced with a new one, allowing for ongoing aesthetics maintenance. This characteristic is especially beneficial in environments prone to wear and tear, such as schools and healthcare facilities.

Compliance and Safety

Understanding Gypsum Access Panels Benefits and Applications

Ceiling T-bar brackets are crucial for the stability and alignment of the T-bar grid system. These brackets connect the T-bars to the building's structural elements, such as walls and ceilings, ensuring that the framework is securely anchored. This is particularly important in spaces where vibrations or movement may occur, as it helps prevent sagging or misalignment over time.

Installation Considerations

4. Safety and Compliance Building codes often require specific access points for maintenance of various systems. A drywall ceiling hatch enables compliance with these codes while maintaining an aesthetically pleasing environment. By providing easy access to critical infrastructure, hatches can help prevent safety hazards associated with neglecting necessary maintenance.

In conclusion, gypsum access panels are indispensable elements in today’s construction landscape, offering the dual benefits of functionality and aesthetics. Their simple installation, versatility, and fire-resistant properties make them well-suited for various applications, whether in homes, offices, or industrial settings. As the demand for efficient and elegant building solutions increases, gypsum access panels will undoubtedly continue to play a crucial role in the design and maintenance of modern buildings. Whether you're a builder, architect, or homeowner, considering these access solutions can greatly enhance both the usability and beauty of your spaces.