high quality screw pump for slurry

Latest articles

Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

high quality screw pump for slurry...

high quality screw pump for slurry 【high quality screw pump for slurry】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

high quality screw pump for slurry...

high quality screw pump for slurry 【high quality screw pump for slurry】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

high quality screw pump for slurry...

high quality screw pump for slurry 【high quality screw pump for slurry】

Read MoreMonitoring

high quality screw pump for slurry...

high quality screw pump for slurry 【high quality screw pump for slurry】

Read MoreThe most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

high quality screw pump for slurry...

high quality screw pump for slurry 【high quality screw pump for slurry】

Read MoreA variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

high quality screw pump for slurry...

high quality screw pump for slurry 【high quality screw pump for slurry】

Read More>Slurry Pump

high quality screw pump for slurry...

high quality screw pump for slurry 【high quality screw pump for slurry】

Read MoreIf you've ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. There's no doubt that the slurry on the pump is hard. But the more you know about what's being pumped, the better your pump selection will be, resulting in longer mean time between failures. Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share the following content with you.

high quality screw pump for slurry...

high quality screw pump for slurry 【high quality screw pump for slurry】

Read MoreFollow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

high quality screw pump for slurry...

high quality screw pump for slurry 【high quality screw pump for slurry】

Read More>Dredge Pump

high quality screw pump for slurry...

high quality screw pump for slurry 【high quality screw pump for slurry】

Read More

Popular articles

- The solution is to choose a >heavy duty slurry pump and, just as importantly, to use a custom built unit with replaceable parts. At Aier Machinery, building your custom slurry pump is one of our areas of expertise. We design your slurry pump to your specifications and application.

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

- The selection of a dredge or , slurry pump, can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

- The Company Adopts Advanced Computer Aided Engineering Software

- Applications of Rubber Lined Slurry Pumps

- Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

Latest articles

-

>Slurry Pump VS Mud Pump

-

-When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

-

Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

-

How does a dredge pump work?

-

High head (i.e. the height to which the pump can move the liquid)

-

- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

Links

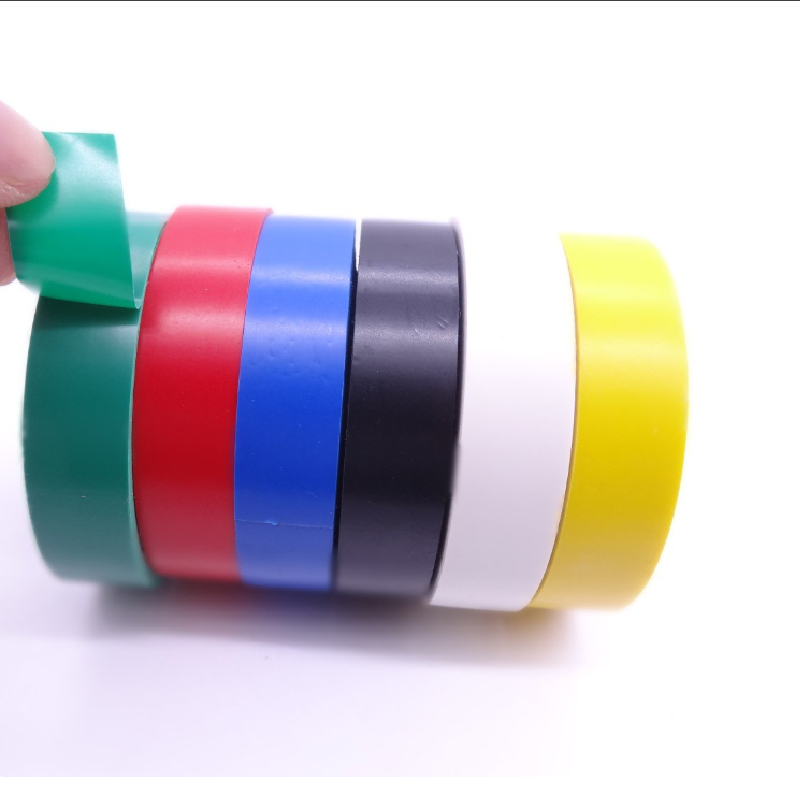

J50 High-voltage EPR Rubber Tape

The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind

The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind pvc insulation tape black.

pvc insulation tape black.Bike Connect is still in development, and its creators are working on adding features that will allow cyclists to use it without looking at their phones. (And, we have to ask—what’s stopping someone in a car from using this?) But it’s a great example of what some crafty technology geeks can do with a few wires, capacitors and a durable outdoor electronics enclosure.

Surface Compatibility

Silicone tape has almost limitless applications, including:

self amalgamating tape 50mm. Available in various materials like rubber, silicone, or polyethylene, it caters to different requirements. For example, rubber tape is ideal for plumbing and gas works due to its water resistance, while silicone tape excels in high-temperature environments typical of automotive and industrial settings.

self amalgamating tape 50mm. Available in various materials like rubber, silicone, or polyethylene, it caters to different requirements. For example, rubber tape is ideal for plumbing and gas works due to its water resistance, while silicone tape excels in high-temperature environments typical of automotive and industrial settings.The Versatility and Importance of 50mm Black Insulation Tape

How To Get Polyethylene Tape

Conclusion

So if you’re working in an environment where the temperature might get that high, it’s always best to go on the side of caution and use a higher-rated tape.

Single Phase Start Control Box

4. Neoprene Rubber Tape: Neoprene rubber tape is a versatile material that is suitable for a wide range of applications. It is known for its resistance to heat, oil, and chemicals, which makes it ideal for automotive and industrial applications.

The Versatility and Benefits of Silicone Insulation Tape

3. Regulatory Compliance Many industries are subject to safety regulations that require proper signage and markings. Utilizing red and white floor marking tape can help businesses comply with these regulations, thereby avoiding potential fines or legal issues.

One of the primary functions of insulation tape is to provide electrical safety. Made from materials that are resistant to electrical currents, yellow insulation tape is commonly used to insulate wires and connections, ensuring safety in electrical installations. Its bright color allows for easy identification and differentiation between various electrical circuits. For safety professionals and electricians, yellow tape often signifies caution or a specific type of wiring, making it an essential tool for clear communication and safety protocol adherence.

High voltage self-fusing rubber tape is widely used in various industries, including