oem 4x3dd slurry pump

Latest articles

What is the pump constructed of?

oem 4x3dd slurry pump...

oem 4x3dd slurry pump 【oem 4x3dd slurry pump】

Read MoreFrom an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

oem 4x3dd slurry pump...

oem 4x3dd slurry pump 【oem 4x3dd slurry pump】

Read MorePumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

oem 4x3dd slurry pump...

oem 4x3dd slurry pump 【oem 4x3dd slurry pump】

Read MoreWY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

oem 4x3dd slurry pump...

oem 4x3dd slurry pump 【oem 4x3dd slurry pump】

Read MoreWhen dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

oem 4x3dd slurry pump...

oem 4x3dd slurry pump 【oem 4x3dd slurry pump】

Read MorePumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

oem 4x3dd slurry pump...

oem 4x3dd slurry pump 【oem 4x3dd slurry pump】

Read MoreHow does a dredge pump work?

oem 4x3dd slurry pump...

oem 4x3dd slurry pump 【oem 4x3dd slurry pump】

Read MoreThe type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

oem 4x3dd slurry pump...

oem 4x3dd slurry pump 【oem 4x3dd slurry pump】

Read MoreTo reduce wear, reduce the pump discharge pressure to the lowest possible point.

oem 4x3dd slurry pump...

oem 4x3dd slurry pump 【oem 4x3dd slurry pump】

Read MoreSlurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

oem 4x3dd slurry pump...

oem 4x3dd slurry pump 【oem 4x3dd slurry pump】

Read More

Popular articles

- - By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

- Compared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

- Critical to the engineering of the pump are heavy duty bearing frames and shafts, extra thick wall sections and easily replaceable wear parts. Total life cycle cost considerations are critical when specifying pumps for severe operating conditions, such as FGD service. High chrome pumps are ideal due to the corrosive pH of the slurry.

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

- Slurry Pump

- - By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

Latest articles

-

Longer maintenance intervals

-

1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

-

When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

-

Vertical Slurry Pump

-

As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

-

WZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

Links

- Jack Hammer Tools The Power behind Precision Work

- A hex shank drill bit, as the name suggests, features a hexagonal-shaped shank, a design that sets it apart from the conventional round shank drill bits. The hexagonal shape, also known as a hex drive, is designed to fit snugly into power tool chucks, providing a more secure grip and reducing slippage during use. This not only enhances safety but also increases drilling precision and efficiency.

Standard profiles are available ex-stock in standard panel sizes however, are able to manufacture and fabricate a range of profiles in Australia to suit your needs. If you have a requirement outside of standard profile, contact our team today to discuss what we can offer you.

FRP demisters ensure that reactions occur with the right amounts of reagents, preventing contamination and fostering efficient reactions FRP demisters ensure that reactions occur with the right amounts of reagents, preventing contamination and fostering efficient reactions

FRP demisters ensure that reactions occur with the right amounts of reagents, preventing contamination and fostering efficient reactions FRP demisters ensure that reactions occur with the right amounts of reagents, preventing contamination and fostering efficient reactions frp demister. For instance, in the production of sulfuric acid, demisters play a pivotal role in separating acid droplets from the gaseous byproducts, ensuring a purer end product.

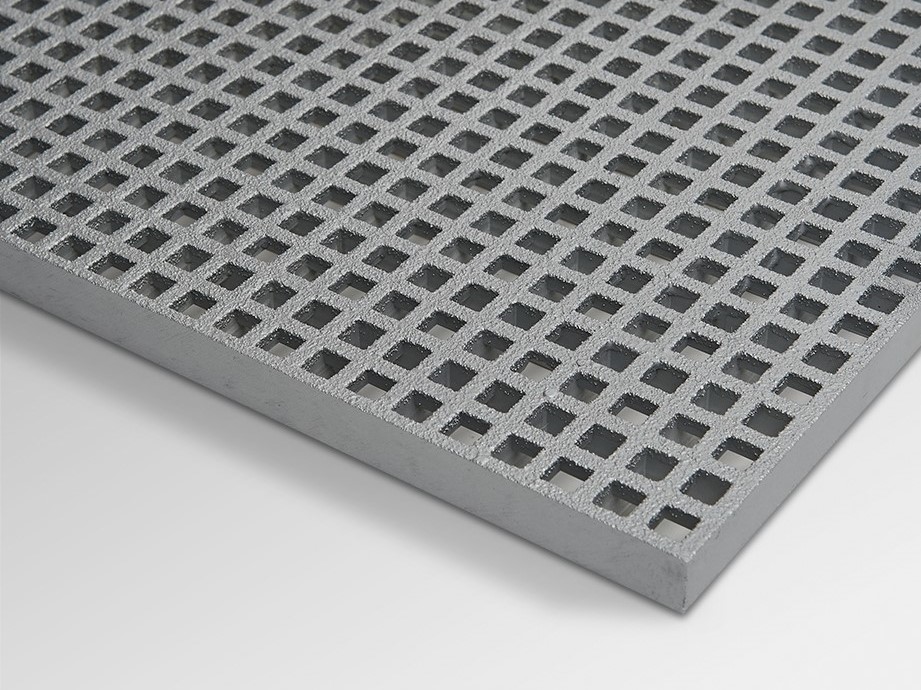

frp demister. For instance, in the production of sulfuric acid, demisters play a pivotal role in separating acid droplets from the gaseous byproducts, ensuring a purer end product.Fiberglass covered grating is corrosion resistant, low maintenance, and strong. This long-lasting fiberglass floor product combines a slip-resistant plate and fiberglass grating, manufactured with any of our resin systems. Our fiberglass covered grating is the ideal choice when a 100% covered flooring surface is needed. It is available with a plate which is bonded to molded or pultruded grating.

Gratings & Covers

spiral rod. DNA, the blueprint of life, is a double spiral rod, with two strands intertwined like a twisted ladder. This structure, discovered by James Watson and Francis Crick, unlocked the secrets of genetic information storage and transfer.

spiral rod. DNA, the blueprint of life, is a double spiral rod, with two strands intertwined like a twisted ladder. This structure, discovered by James Watson and Francis Crick, unlocked the secrets of genetic information storage and transfer. ati r38. With its compact size and sleek aesthetics, the ATI R38 is sure to turn heads and make a statement wherever you take it.

ati r38. With its compact size and sleek aesthetics, the ATI R38 is sure to turn heads and make a statement wherever you take it.

tapered rock button drill bits.

If you work in construction in any way, you will most likely need to use FRP grating at some point.