high quality polyurethane slurry pump suppliers

Latest articles

Types of slurry pumps

high quality polyurethane slurry pump suppliers...

high quality polyurethane slurry pump suppliers 【high quality polyurethane slurry pump suppliers】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

high quality polyurethane slurry pump suppliers...

high quality polyurethane slurry pump suppliers 【high quality polyurethane slurry pump suppliers】

Read MoreAs a pump supplier, Aier is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc. If you want to get more information about >best slurry pump wholesale, welcome to >contact us today or request a quote.

high quality polyurethane slurry pump suppliers...

high quality polyurethane slurry pump suppliers 【high quality polyurethane slurry pump suppliers】

Read MorePump selection for FGD

high quality polyurethane slurry pump suppliers...

high quality polyurethane slurry pump suppliers 【high quality polyurethane slurry pump suppliers】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

high quality polyurethane slurry pump suppliers...

high quality polyurethane slurry pump suppliers 【high quality polyurethane slurry pump suppliers】

Read MorePumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

high quality polyurethane slurry pump suppliers...

high quality polyurethane slurry pump suppliers 【high quality polyurethane slurry pump suppliers】

Read MoreAier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

high quality polyurethane slurry pump suppliers...

high quality polyurethane slurry pump suppliers 【high quality polyurethane slurry pump suppliers】

Read MoreWhat is Heavy Duty Slurry Pump?

high quality polyurethane slurry pump suppliers...

high quality polyurethane slurry pump suppliers 【high quality polyurethane slurry pump suppliers】

Read MoreSome quench seals are planned to replace the tight fitting outlet restriction with a secondary seal and a top outlet that can be piped to capture the used quench fluid and drain it from the rotating assembly. However the principle is the same, we try to cool the seal rather than flush it in any way.

high quality polyurethane slurry pump suppliers...

high quality polyurethane slurry pump suppliers 【high quality polyurethane slurry pump suppliers】

Read MoreAs new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

high quality polyurethane slurry pump suppliers...

high quality polyurethane slurry pump suppliers 【high quality polyurethane slurry pump suppliers】

Read More

Popular articles

- >Vertical Slurry Pump

- - Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

- We know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

- How does a dredge pump work?

- Step 2

- What is a slurry pump?

Latest articles

-

Larger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

-

As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

-

The same point of slurry pump and mud pump

-

Slurry Pump

-

What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. >Slurry pumps are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

-

Types of damage to slurry pumps

Links

- Moreover, the T38 drill rod is ergonomically designed, with a balance point that ensures ease of handling for the operator. Its ergonomic grip reduces operator fatigue during extended drilling sessions, contributing to a more comfortable and safer working environment.

- In terms of maintenance, fiberglass tanks score high

Unlike traditional metals that corrode over time, affecting the vehicle's structural integrity and aesthetic appeal, fiberglass bodies maintain their pristine condition with minimal maintenance Unlike traditional metals that corrode over time, affecting the vehicle's structural integrity and aesthetic appeal, fiberglass bodies maintain their pristine condition with minimal maintenance

Unlike traditional metals that corrode over time, affecting the vehicle's structural integrity and aesthetic appeal, fiberglass bodies maintain their pristine condition with minimal maintenance Unlike traditional metals that corrode over time, affecting the vehicle's structural integrity and aesthetic appeal, fiberglass bodies maintain their pristine condition with minimal maintenance fiberglass car. This durability means fewer trips to the repair shop and a longer lifespan for the vehicle, providing economic benefits for owners in the long run.

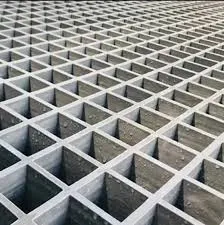

fiberglass car. This durability means fewer trips to the repair shop and a longer lifespan for the vehicle, providing economic benefits for owners in the long run.Fiberglass covered grating is a long-lasting, molded fiberglass floor product that combines smooth, gritted, or checker plate and molded grating manufactured with any of our resin systems. It is the ideal choice when a 100% covered flooring surface is needed. Our fiberglass covered grating is often used in loading and storage areas with high foot and cart traffic. This is where a strong, level surface is ideal, and this is why fiberglass covered grating is ideal. If offers approximately 50% higher stiffness values than that of open mesh grating, and its standard grit-top cover assures secure footing. For more on fiberglass covered grating, click here.

This not only improves system performance but also contributes to sustainability goals by optimizing energy usage This not only improves system performance but also contributes to sustainability goals by optimizing energy usage

This not only improves system performance but also contributes to sustainability goals by optimizing energy usage This not only improves system performance but also contributes to sustainability goals by optimizing energy usage large diameter fiberglass pipe.

large diameter fiberglass pipe.2.Conductive fiberglass grating

Fibergalss grating itself is an insulator, non conductive, non thermal conductivity, but in some specific places, it also has a conductive requirements. The detailed operation method is to eliminate the damage of static charge inoculation in the rock layer with a thickness of about 3~5mm. The conductive grating also has same characteristics with traditional glass steel grille ,such as corrosion resistance, flame retardant,anti strike, skid resistance, light weight and practical in refinery and armaments manufacturing factory, high-tech industry, computer room, chemical plants, dry areas and underground mining operations.

If you have heard of fiberglass grating, you may have wondered what it was and how it was used, especially as it is such a popular construction material on various sites.

In addition to breaking up hard materials, this tool can also be used for a variety of other tasks, such as drilling holes, chiseling, and prying In addition to breaking up hard materials, this tool can also be used for a variety of other tasks, such as drilling holes, chiseling, and prying

In addition to breaking up hard materials, this tool can also be used for a variety of other tasks, such as drilling holes, chiseling, and prying In addition to breaking up hard materials, this tool can also be used for a variety of other tasks, such as drilling holes, chiseling, and prying hand held jack hammer. The adjustable stroke length and variable speed settings allow users to customize the tool to their specific needs, making it a highly adaptable tool for a wide range of applications.

hand held jack hammer. The adjustable stroke length and variable speed settings allow users to customize the tool to their specific needs, making it a highly adaptable tool for a wide range of applications. 90 lb pneumatic jackhammer. It can be used for a wide range of applications, from breaking up concrete slabs and foundations to digging trenches and boreholes. Its compact size and light weight also make it highly portable, allowing workers to move it easily from one job site to another.

90 lb pneumatic jackhammer. It can be used for a wide range of applications, from breaking up concrete slabs and foundations to digging trenches and boreholes. Its compact size and light weight also make it highly portable, allowing workers to move it easily from one job site to another. Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas

Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas

This characteristic is particularly valuable in industries like petrochemicals, where processes often involve high-temperature operations This characteristic is particularly valuable in industries like petrochemicals, where processes often involve high-temperature operations

This characteristic is particularly valuable in industries like petrochemicals, where processes often involve high-temperature operations This characteristic is particularly valuable in industries like petrochemicals, where processes often involve high-temperature operations