slurry pump impeller type factories

Latest articles

Slurry Pump

slurry pump impeller type factories...

slurry pump impeller type factories 【slurry pump impeller type factories】

Read MoreWZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

slurry pump impeller type factories...

slurry pump impeller type factories 【slurry pump impeller type factories】

Read MoreAier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

slurry pump impeller type factories...

slurry pump impeller type factories 【slurry pump impeller type factories】

Read More>Vertical Slurry Pump

slurry pump impeller type factories...

slurry pump impeller type factories 【slurry pump impeller type factories】

Read MoreChromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

slurry pump impeller type factories...

slurry pump impeller type factories 【slurry pump impeller type factories】

Read MoreSubmersible Slurry Pump

slurry pump impeller type factories...

slurry pump impeller type factories 【slurry pump impeller type factories】

Read MoreTo reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

slurry pump impeller type factories...

slurry pump impeller type factories 【slurry pump impeller type factories】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

slurry pump impeller type factories...

slurry pump impeller type factories 【slurry pump impeller type factories】

Read More- Low noise level - Operating underwater results in low noise or even silent operation.

slurry pump impeller type factories...

slurry pump impeller type factories 【slurry pump impeller type factories】

Read MoreWA Heavy-duty Slurry Pump

slurry pump impeller type factories...

slurry pump impeller type factories 【slurry pump impeller type factories】

Read More

Popular articles

- The concept of the , slurry pump, and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

- The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

- Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

- Typically, slurries are.

- Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

- Types of slurry pumps

Latest articles

-

I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

-

Slurry pump considerations

-

Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

-

When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

-

Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

-

Another important target=_blank title=Part of the Slurry Pump>part of the slurry pump is its casing, which bears all the pressure. The slurry pump casing should have a large clearance between the impeller and the diversion angle to reduce wear and prevent large solid particles from getting stuck. Due to the extra space, there is more recirculation in the slurry pump casing under various operating conditions. Again, this accelerates wear compared to typical pumps.

Links

Assembling the oil seals is only possible with the right assembly tools. Due to the high risk of damage during assembly, it is important that you have tools with which you can work carefully. A bearing fitting tool set is ideal.

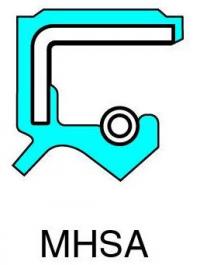

INTRODUCTION TO OIL SEALS AND HOW THEY ARE USED

different types of spark plugs.

Oil seals in the motor, including the engine and other critical components, are essential for maintaining the integrity and efficiency of the vehicle. These seals are designed to contain lubricating oil and prevent leaks, contributing to the smooth operation and longevity of the motor. Proper maintenance and replacement of oil seals in the motor are crucial for the reliability and performance of the vehicle's systems.

Oil seals serve an important function in preventing lubricant leaks by closing in the spaces between the parts of the rotary shaft equipment. They also prevent dirt, dust, and other contaminants from clogging up the unit. Having them properly installed enables engines, pumps, and pipes to operate more efficiently.

The last step involves the actual pressing-in of the seal. There are tools and tool kits available that can help with seal installation. Their biggest benefit is that they apply a very uniform force to the seal case, eliminating the possibility of the seal seating in any way other than flush.

One of the main causes of black spark plugs is a rich air-fuel mixture. This means that there is an excess of fuel in the combustion chamber, which can lead to incomplete combustion and the production of carbon deposits. A rich air-fuel mixture can be caused by a variety of factors, including a faulty oxygen sensor, a clogged air filter, or a malfunctioning fuel injector. It is important to address these issues promptly to prevent further damage to the spark plugs and the engine.

black spark plug

Compounds for Automotive Power Train Systems

Copper and nickel are relatively inexpensive, while platinum is much more expensive but also much more durable and resistant to wear Copper and nickel are relatively inexpensive, while platinum is much more expensive but also much more durable and resistant to wear

Copper and nickel are relatively inexpensive, while platinum is much more expensive but also much more durable and resistant to wear Copper and nickel are relatively inexpensive, while platinum is much more expensive but also much more durable and resistant to wear car spark plug price.

car spark plug price.

c15 valve cover gasket. If dirt or debris were to enter the engine, it could cause damage to sensitive components such as the valves and camshafts. By maintaining a tight seal with the valve cover gasket, you can keep your engine clean and free from contaminants.

spring loaded

As a result, engines run smoother and more efficiently, leading to better fuel economy and reduced wear on engine components As a result, engines run smoother and more efficiently, leading to better fuel economy and reduced wear on engine components

As a result, engines run smoother and more efficiently, leading to better fuel economy and reduced wear on engine components As a result, engines run smoother and more efficiently, leading to better fuel economy and reduced wear on engine components