china warman slurry pump drawings factory

Latest articles

A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

china warman slurry pump drawings factory...

china warman slurry pump drawings factory 【china warman slurry pump drawings factory】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

china warman slurry pump drawings factory...

china warman slurry pump drawings factory 【china warman slurry pump drawings factory】

Read MoreDry Installation

china warman slurry pump drawings factory...

china warman slurry pump drawings factory 【china warman slurry pump drawings factory】

Read MoreFor example.

china warman slurry pump drawings factory...

china warman slurry pump drawings factory 【china warman slurry pump drawings factory】

Read MoreWith the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

china warman slurry pump drawings factory...

china warman slurry pump drawings factory 【china warman slurry pump drawings factory】

Read MoreIn harsh conditions with sand, sludge, rocks and mud, ordinary slurry pumps tend to clog, wear and fail frequently. But WA heavy duty slurry pumps are highly resistant to wear and corrosion, which means that the service life of our slurry pumps is better than other manufacturers' pumps.

china warman slurry pump drawings factory...

china warman slurry pump drawings factory 【china warman slurry pump drawings factory】

Read More-When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

china warman slurry pump drawings factory...

china warman slurry pump drawings factory 【china warman slurry pump drawings factory】

Read More>Slurry Pump vs Mud Pump

china warman slurry pump drawings factory...

china warman slurry pump drawings factory 【china warman slurry pump drawings factory】

Read MoreIf you've ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. There's no doubt that the slurry on the pump is hard. But the more you know about what's being pumped, the better your pump selection will be, resulting in longer mean time between failures. Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share the following content with you.

china warman slurry pump drawings factory...

china warman slurry pump drawings factory 【china warman slurry pump drawings factory】

Read MoreDetermine the operating parameters of the pump.

china warman slurry pump drawings factory...

china warman slurry pump drawings factory 【china warman slurry pump drawings factory】

Read More

Popular articles

- Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

- A target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

- As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

- >Slurry Pump

Latest articles

-

Submersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

-

Slurry Pump

-

How to Choose a Dredging Pump or Slurry Pump

-

In this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

-

When pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

-

Follow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

Links

- Machines and motors which run hot

- When evaluating PVC insulation tape manufacturers, potential buyers should consider several factors. Firstly, the reputation of the manufacturer is paramount. Look into their history, client testimonials, and any industry accolades they may have received. A manufacturer with a proven track record of delivering high-quality products is more likely to meet your needs.

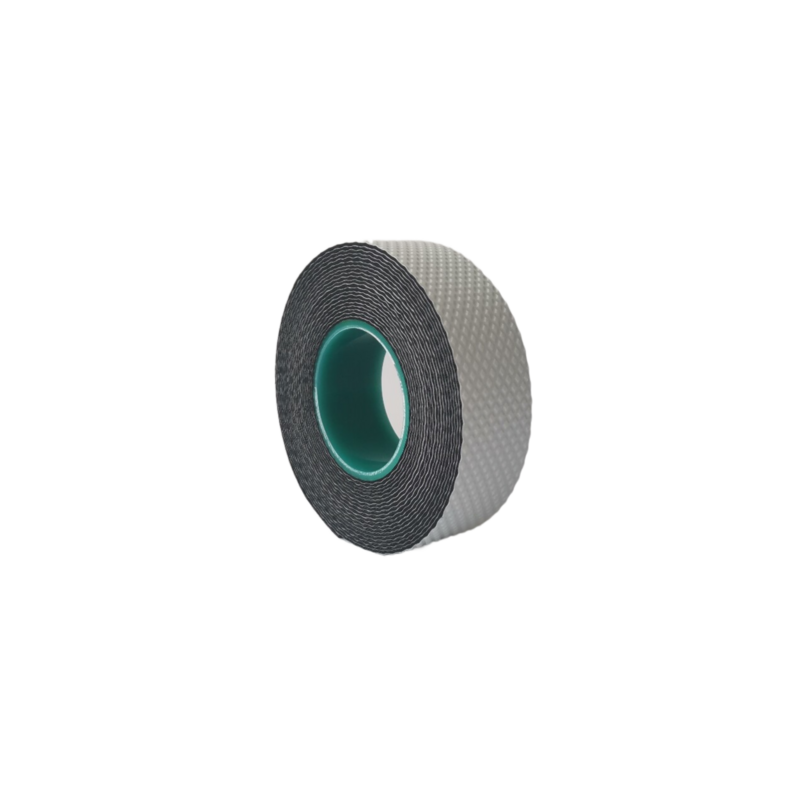

Self-fusing rubber tape finds usage across a wide spectrum of applications. In the electrical industry, it is commonly used for insulating wires and connections, providing a reliable shield against water and other environmental factors. It can also be employed to repair damaged cables, extending their lifespan with minimal effort.

- 2

- Black insulation tape is a versatile and essential material used in various industries for its excellent insulating properties. This article aims to provide a comprehensive guide to black insulation tape price, including factors affecting the cost, common uses, and where to buy it at an affordable price.

- The Art of Self-Amalgamation A Journey Through Tape

It is available in 44 different models of built-in one-piece structure extruded, including 1pc main enclosure, 1pc front panel, and 1pc rear panels—good heat dissipation, easy to be assembled.

- When comparing prices for floor marking tape, it is important to consider the overall value of the product. It is not just about finding the cheapest option, but rather finding a tape that offers the best combination of price, durability, and functionality for your specific needs. Investing in high-quality floor marking tape can help prevent accidents, improve efficiency, and maintain a professional and organized work environment.

- One of the primary functions of automotive wire wrap tape is to secure and organize wiring harnesses. These bundles of wires are the nervous system of a vehicle, carrying signals and power to various components. Without proper organization, these wires can become tangled or damaged, leading to malfunctions or even safety hazards. By wrapping them in this specialized tape, mechanics can ensure that the wires remain in place, protected from abrasion and environmental contaminants.

Silicone tape is different from silicone sheets. Silicone sheets are used for protecting wounds and scars in medical settings. Silicone sheeting is also used in the food, drink, manufacturing and pharmaceutical industries due to its heat resistance, hygienic qualities and versatility.

electrical insulation cotton tape. It can withstand temperatures ranging from -40°C to 105°C, making it an ideal choice for outdoor and industrial applications. Additionally, its non-adhesive backing ensures that it will not stick to the surface it is wrapped around, making it easy to remove without leaving residue.

electrical insulation cotton tape. It can withstand temperatures ranging from -40°C to 105°C, making it an ideal choice for outdoor and industrial applications. Additionally, its non-adhesive backing ensures that it will not stick to the surface it is wrapped around, making it easy to remove without leaving residue.BUTYL RUBBER TAPE

Beyond its remarkable versatility, silicone self-adhesive tape offers several key advantages:

epr self amalgamating tape. It can also be used for sealing and repairing plumbing leaks, making it a handy tool to have in any toolbox. Additionally, the tape is chemically resistant, making it suitable for use in a variety of industrial settings.

3M rubber tapes have operating temperatures ranging from 176°F (80°C) to 221°F (105°C). Some, like Scotch® Linerless Rubber Splicing Tape 130C and Rubber Splicing Tape 23, have overloads temperatures up to 266°F (130°C). Because of this high heat attribute; there are many industrial settings where it is common to use rubber tape in lower voltage applications to moisture seal, pad and insulate:

The ease of use of Flex Tape is also worth noting. The tape comes in a variety of sizes, making it easy to find the right width for your specific project. It can be cut to your desired length, and it adheres quickly upon contact. This means that even individuals with little to no handyman experience can successfully complete repairs without the need for specialized tools. Simply peel off the backing, apply it to the surface, press down firmly, and you’re done!

Butyl tape is a versatile material that is available in various thicknesses and widths. You can purchase it as rolls or pre-cut pieces to better fit the scope of your project. There are many grades available that boast distinct properties for different uses.

https://www.fastenersystems.com/products/assorted-tape

automotive fabric tape. They can withstand extreme temperatures, UV radiation, and other environmental factors that can cause other types of tapes to degrade over time. This makes them a popular choice for use in outdoor applications, such as on the roofs and hoods of vehicles, where they can provide long-lasting protection against the elements.

automotive fabric tape. They can withstand extreme temperatures, UV radiation, and other environmental factors that can cause other types of tapes to degrade over time. This makes them a popular choice for use in outdoor applications, such as on the roofs and hoods of vehicles, where they can provide long-lasting protection against the elements.Natural rubber

2. Durability and Longevity Butyl rubber sheets exhibit remarkable resistance to various weather conditions, including extreme temperatures, UV light, and ozone exposure. This durability means that roofs made from butyl rubber can last significantly longer than traditional roofing materials, reducing the need for frequent replacements and repairs.

butyl rubber roofing sheet