submersible pump

Latest articles

Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

submersible pump...

submersible pump 【submersible pump】

Read More>Slurry Pump VS Mud Pump

submersible pump...

submersible pump 【submersible pump】

Read MoreChromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

submersible pump...

submersible pump 【submersible pump】

Read MoreNon-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

submersible pump...

submersible pump 【submersible pump】

Read MoreHydrostatic head - i.e. the height to which the slurry must be lifted in the piping system.

submersible pump...

submersible pump 【submersible pump】

Read MoreTwo types of slurry are found in these industries.

submersible pump...

submersible pump 【submersible pump】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

submersible pump...

submersible pump 【submersible pump】

Read MoreThe FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

submersible pump...

submersible pump 【submersible pump】

Read MoreFind a professional slurry pump supplier

submersible pump...

submersible pump 【submersible pump】

Read MoreBecause of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

submersible pump...

submersible pump 【submersible pump】

Read More

Popular articles

- With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

- Choosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

- If you want to know more information about the best heavy duty slurry pump, welcome to >contact us today or request a quote.

- - Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

- With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

- Pumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

Latest articles

-

It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

-

The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

-

Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

-

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

-

High head (i.e. the height to which the pump can move the liquid)

-

Choosing The Right Slurry Pump For Your Application

Links

- Blue enamel cooking pots are not merely tools for sustenance; they are heirlooms that connect us to our culinary past while serving our present needs. They remind us that sometimes, the most functional items can also be the most beautiful, adding a touch of heritage and tradition to the simplest of meals.

Materials

Professional Kitchens: In professional kitchens, black cast iron griddles and grill pans are essential tools for achieving consistent and high-quality results. They are used for searing steaks, grilling vegetables, and creating signature dishes with distinctive grill marks.

Baking soda can be a powerful ally in this case Baking soda can be a powerful ally in this case

Baking soda can be a powerful ally in this case Baking soda can be a powerful ally in this case cleaning a rusty cast iron griddle. Make a paste by mixing baking soda with water until it reaches a toothpaste-like consistency. Apply this paste liberally onto the rust spots and let it sit for about an hour. Then, using a steel wool pad or a non-abrasive scrubber, scrub the rust away. Rinse well and dry thoroughly.

cleaning a rusty cast iron griddle. Make a paste by mixing baking soda with water until it reaches a toothpaste-like consistency. Apply this paste liberally onto the rust spots and let it sit for about an hour. Then, using a steel wool pad or a non-abrasive scrubber, scrub the rust away. Rinse well and dry thoroughly.

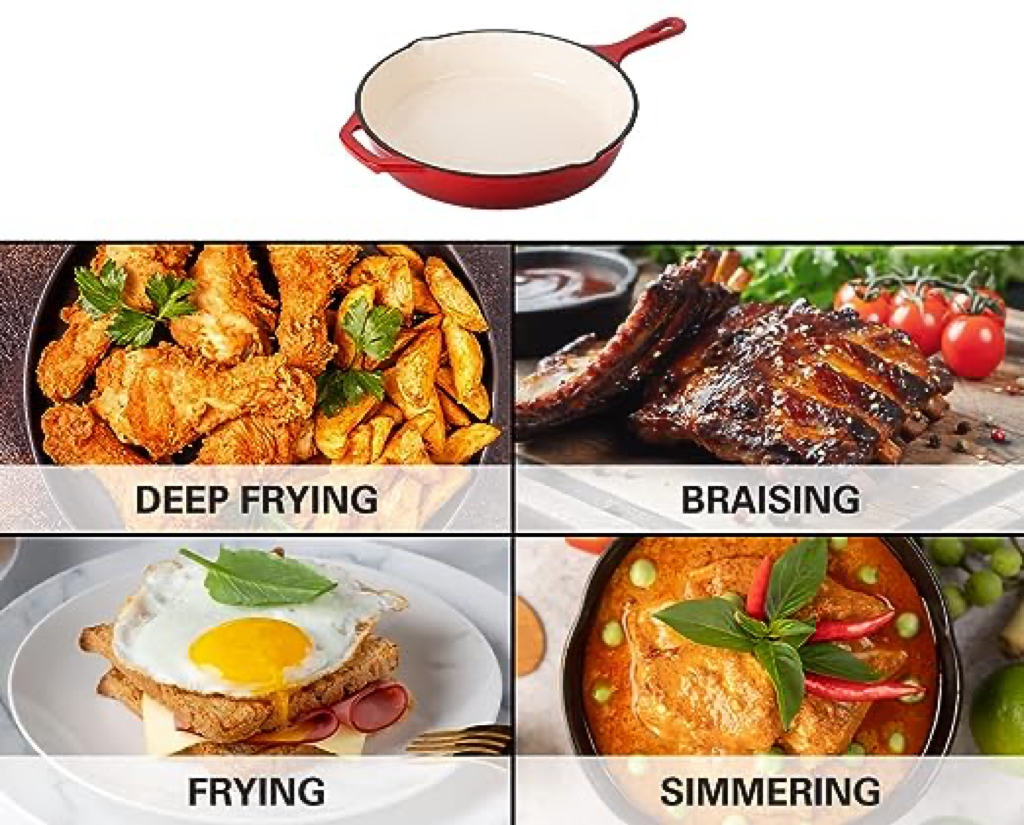

enamel coated cast iron frying pan.

Its weight adds stability during cooking, preventing sliding or tipping, and its robust build ensures a lifetime of service if cared for properly Its weight adds stability during cooking, preventing sliding or tipping, and its robust build ensures a lifetime of service if cared for properly

Its weight adds stability during cooking, preventing sliding or tipping, and its robust build ensures a lifetime of service if cared for properly Its weight adds stability during cooking, preventing sliding or tipping, and its robust build ensures a lifetime of service if cared for properly double sided cast iron griddle.

double sided cast iron griddle.

Pans are open to even more interpretation. While most cooks consider a pan to be a sauté pan, the term often refers to all types of cooking vessels. The phrase “pots and pans” is synonymous with general cookware, and “pan” is commonly used when describing other pieces — crepe pan, sheet pan, roasting pan, and the like.

Once the bacon begins to sizzle and release some fat, carefully position the bacon press on top of the bacon slices. Ensure that the press is evenly distributed over the bacon to promote uniform cooking.

Why chefs prefer stainless steel cookware over aluminium cookware?

Regular seasoning with oil helps prevent rusting and creates a non-stick surface, eliminating the need for excessive oil or butter during cooking Regular seasoning with oil helps prevent rusting and creates a non-stick surface, eliminating the need for excessive oil or butter during cooking

Regular seasoning with oil helps prevent rusting and creates a non-stick surface, eliminating the need for excessive oil or butter during cooking Regular seasoning with oil helps prevent rusting and creates a non-stick surface, eliminating the need for excessive oil or butter during cooking stovetop cast iron grill pan. This not only makes cleaning easier but also enhances the pan's performance with each use.

stovetop cast iron grill pan. This not only makes cleaning easier but also enhances the pan's performance with each use. large cast iron fry pan. Once heated, the entire surface of the pan becomes hot, ensuring that your food cooks evenly without any hot spots. This makes it perfect for dishes that require long cooking times or multiple ingredients. The even heat distribution also means that you can achieve a perfect sear on your steaks or a crispy crust on your cornbread.

large cast iron fry pan. Once heated, the entire surface of the pan becomes hot, ensuring that your food cooks evenly without any hot spots. This makes it perfect for dishes that require long cooking times or multiple ingredients. The even heat distribution also means that you can achieve a perfect sear on your steaks or a crispy crust on your cornbread.Ready to Shop?

However, it's worth noting that while enamel is generally chip-resistant, it's not completely indestructible However, it's worth noting that while enamel is generally chip-resistant, it's not completely indestructible

However, it's worth noting that while enamel is generally chip-resistant, it's not completely indestructible However, it's worth noting that while enamel is generally chip-resistant, it's not completely indestructible enamel cook set. Careful handling and avoiding sudden temperature changes can prevent damage.

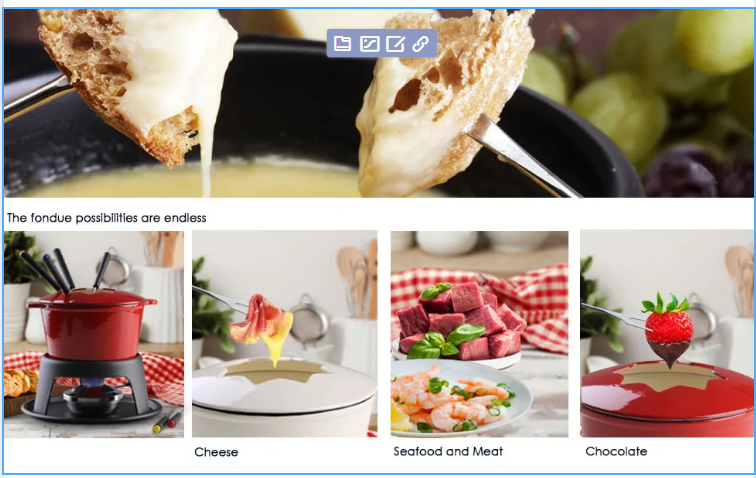

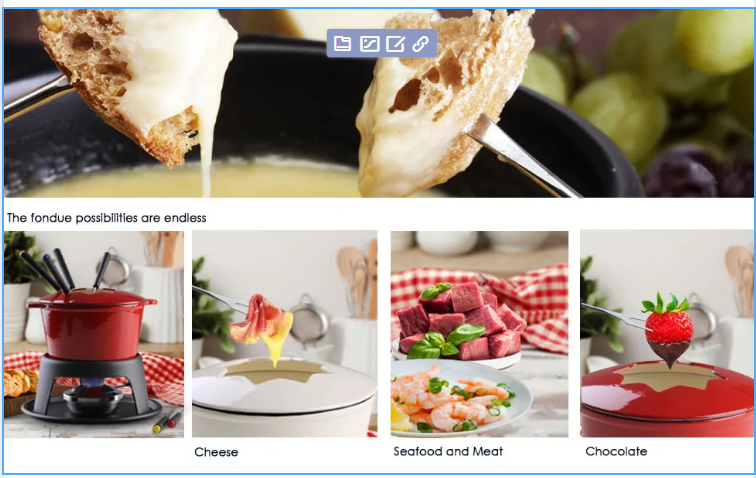

enamel cook set. Careful handling and avoiding sudden temperature changes can prevent damage. enamel cast iron fondue set. You can use it to make a variety of fondues, including cheese, chocolate, and even savory options like oil or broth-based dips. The set usually includes a pot, forked skewers, and a stand, making it easy to serve and enjoy your fondue in style.

enamel cast iron fondue set. You can use it to make a variety of fondues, including cheese, chocolate, and even savory options like oil or broth-based dips. The set usually includes a pot, forked skewers, and a stand, making it easy to serve and enjoy your fondue in style.Stainless steel pans are a classic in both home and restaurant kitchens—not just because they look professional. Quick to heat up, incredibly responsive to temperature change, and lightweight enough for easy flipping and tossing, high-quality stainless steel does an excellent job cooking everything from delicate vegetables to thick, bone-in steaks and chops.