china slurry pump components

Latest articles

Determine the nature of the material to be pumped

china slurry pump components...

china slurry pump components 【china slurry pump components】

Read MoreWhen dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

china slurry pump components...

china slurry pump components 【china slurry pump components】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

china slurry pump components...

china slurry pump components 【china slurry pump components】

Read MoreMagnetite mixing

china slurry pump components...

china slurry pump components 【china slurry pump components】

Read More- Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

china slurry pump components...

china slurry pump components 【china slurry pump components】

Read MoreFor more information about this new and improved pump, please contact us.

china slurry pump components...

china slurry pump components 【china slurry pump components】

Read MoreSubmersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

china slurry pump components...

china slurry pump components 【china slurry pump components】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

china slurry pump components...

china slurry pump components 【china slurry pump components】

Read MoreConsider the impeller. Slurry pumps must have thicker vanes than water pumps to prevent wear. Due to the increased thickness, there will be fewer vanes, otherwise the passages will be too narrow and will affect the performance of the pump. The impeller should have a large enough passage so that the largest solid particles can pass through without clogging.

china slurry pump components...

china slurry pump components 【china slurry pump components】

Read MoreChoosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

china slurry pump components...

china slurry pump components 【china slurry pump components】

Read More

Popular articles

- A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

- of a thick consistency, and.

- To find out more about Aier slurry Pumps, please >contact us.

- Make sure you follow the basic rules of pump piping.

- What is a dredging pump?

- Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

Latest articles

-

- Keeping clean catch basins clean from solids

-

Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

-

Slurry Pump Selection

-

As a pump supplier, Aier is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc. If you want to get more information about >best slurry pump wholesale, welcome to >contact us today or request a quote.

-

BCT Ceramic Slurry Pumps

-

The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

Links

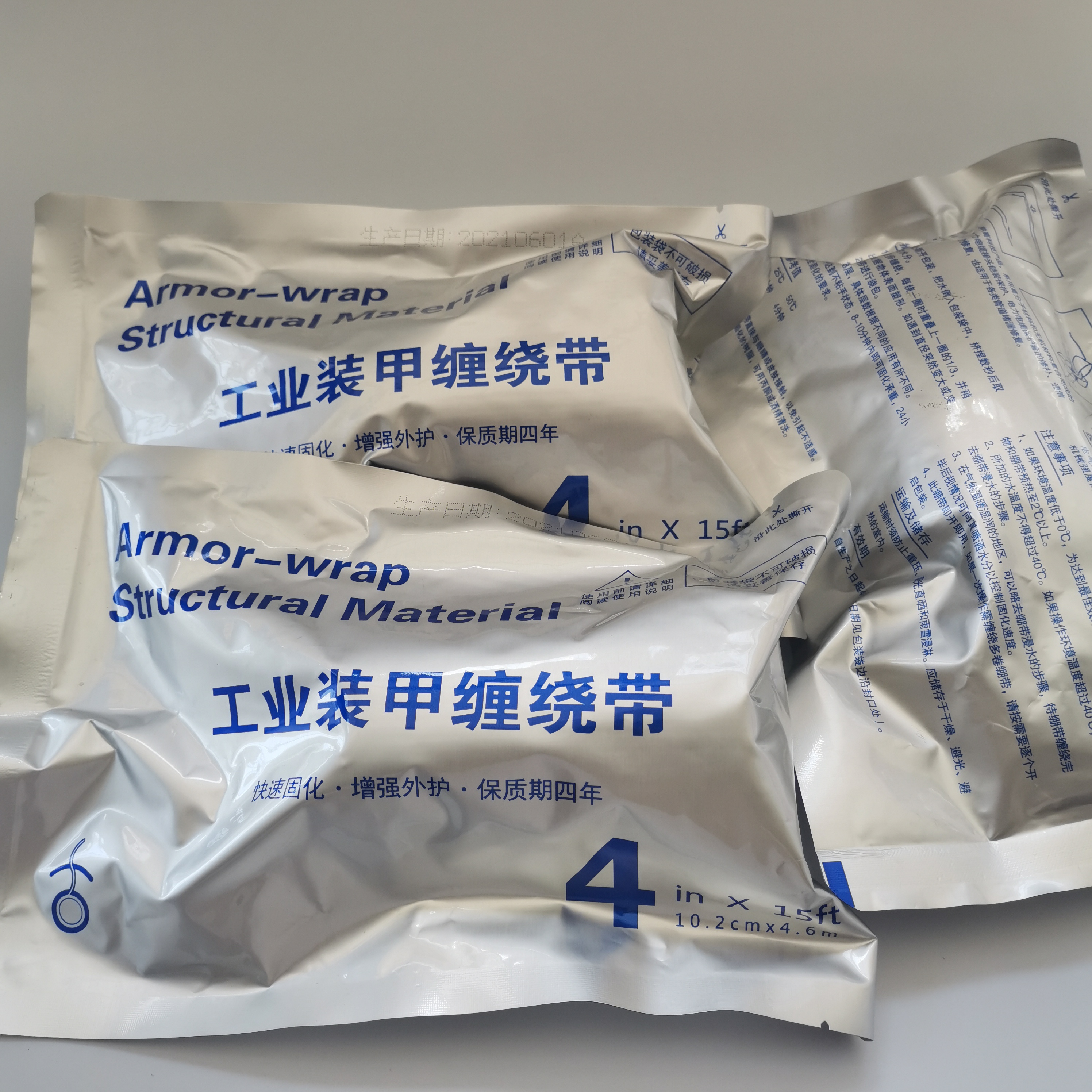

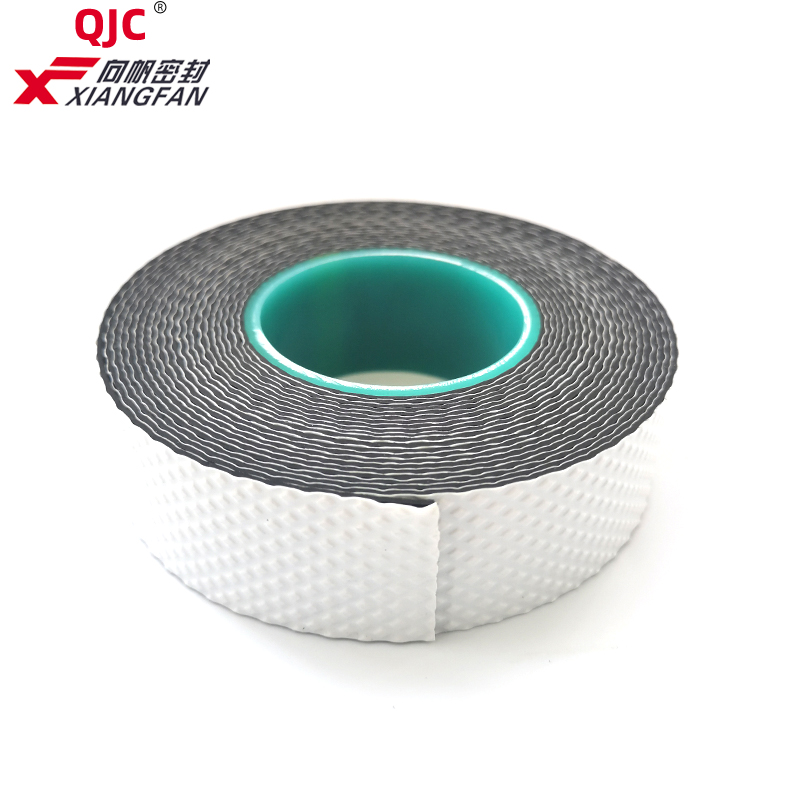

- Butyl tape is less temperature-sensitive than natural rubber

- When using rubber tape to stop water leaks, it is important to choose the right type of tape for the job. There are various types of rubber tape available, including self-fusing tape, silicone tape, and butyl tape. Each type has its own unique properties and is specifically designed for different applications. It is important to read the manufacturer's instructions carefully and select the appropriate tape for the specific leak you are trying to fix.

Natural rubber

rubber tape to stop water leaks. It is commonly used to repair plumbing pipes, seal windows and doors, and patch up holes and cracks in walls. Its versatility and ease of use make it a must-have item for any DIY enthusiast or homeowner.

automotive electrical tape fabric. Wire and cable insulation Automotive electrical tape is commonly used to insulate wires and cables to prevent short circuits and electrical interference.

automotive electrical tape fabric. Wire and cable insulation Automotive electrical tape is commonly used to insulate wires and cables to prevent short circuits and electrical interference.Easy Implementation and Versatility

This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas

This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas This makes it an ideal solution for outdoor applications, such as sealing roof flashings, gutters, and other exposed areas foil backed butyl tape.

foil backed butyl tape.3. Measure and Cut Measure the length of the gap that needs sealing and cut the butyl weather stripping accordingly. It’s advisable to cut a little longer than necessary, allowing for a snug fit.

Safety and Hazard Marking

Butyl Rubber Tape

hazard floor tape. Choose the appropriate type of tape based on the specific hazard being marked and the environment in which it will be used.

hazard floor tape. Choose the appropriate type of tape based on the specific hazard being marked and the environment in which it will be used.Understanding Butyl Rubber