china portable submersible slurry pump manufacturer

Latest articles

Pumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

china portable submersible slurry pump manufacturer...

china portable submersible slurry pump manufacturer 【china portable submersible slurry pump manufacturer】

Read MoreAier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

china portable submersible slurry pump manufacturer...

china portable submersible slurry pump manufacturer 【china portable submersible slurry pump manufacturer】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

china portable submersible slurry pump manufacturer...

china portable submersible slurry pump manufacturer 【china portable submersible slurry pump manufacturer】

Read MoreWe know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

china portable submersible slurry pump manufacturer...

china portable submersible slurry pump manufacturer 【china portable submersible slurry pump manufacturer】

Read MoreSlurry pump considerations

china portable submersible slurry pump manufacturer...

china portable submersible slurry pump manufacturer 【china portable submersible slurry pump manufacturer】

Read MoreRubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

china portable submersible slurry pump manufacturer...

china portable submersible slurry pump manufacturer 【china portable submersible slurry pump manufacturer】

Read MoreIf you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

china portable submersible slurry pump manufacturer...

china portable submersible slurry pump manufacturer 【china portable submersible slurry pump manufacturer】

Read MoreLess downtime

china portable submersible slurry pump manufacturer...

china portable submersible slurry pump manufacturer 【china portable submersible slurry pump manufacturer】

Read MoreOn the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

china portable submersible slurry pump manufacturer...

china portable submersible slurry pump manufacturer 【china portable submersible slurry pump manufacturer】

Read MoreSlurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

china portable submersible slurry pump manufacturer...

china portable submersible slurry pump manufacturer 【china portable submersible slurry pump manufacturer】

Read More

Popular articles

- It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

- What is Heavy Duty Slurry Pump?

- Conveying medium

- Other manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

- What is a dredging pump?

- Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

Latest articles

-

Horizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

-

Conveying medium

-

Selecting a dredge pump

-

3. Both pumps and motors are designed separately.

-

What is a slurry?

-

The terms slurry pump and dredge pump can be used interchangeably.

Links

The Gambrel Barn Design

Conclusion

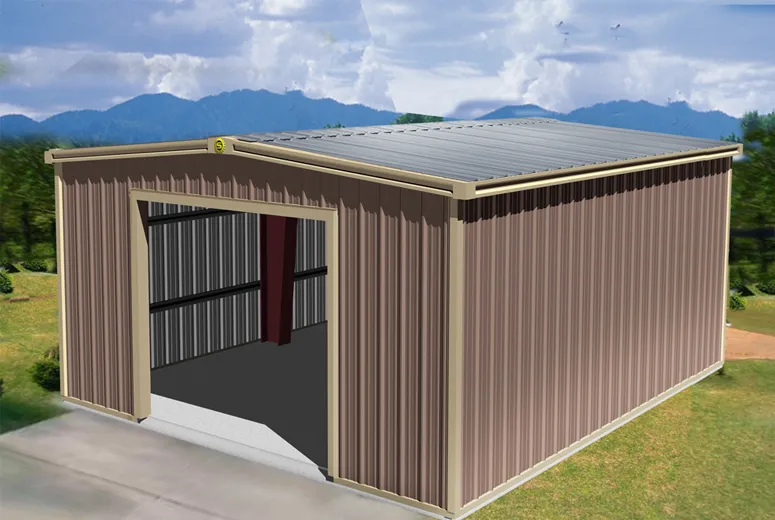

In recent years, pre-manufactured steel buildings have emerged as a popular choice for various construction needs. From commercial warehouses to residential homes, the advantages of using steel in building projects are becoming increasingly recognized by architects, builders, and homeowners alike. With its durability, cost-effectiveness, and design versatility, pre-manufactured steel structures represent a significant advancement in construction technology.

Farm buildings serve various purposes, from housing livestock to storing equipment and crops. The design and construction of these structures significantly impact the efficiency of farming operations. New farm buildings are designed with precision, taking into consideration not only the needs of the farmer but also those of the animals and the environment.

Whether in logistics, manufacturing, or retail, steel structure warehouses provide the adaptable infrastructure needed to thrive in a competitive market. As technology advances and construction processes improve, the role of steel in warehouse construction is poised to grow even further, solidifying its place at the forefront of modern architecture. With durability and efficiency at the core, the future of warehousing is undeniably steel.

6. Weather Resistance Steel frame sheds are designed to withstand harsh weather conditions. Their robust construction ensures that they can endure heavy rains, strong winds, and snow accumulation without compromising structural integrity. This reliability makes them an ideal choice for regions prone to extreme weather.

Light gauge steel framing involves using thin steel sections, typically ranging from 20 to 25 gauge, to construct the structural framework of a building. This method is increasingly favored over traditional wood framing due to its numerous benefits. Firstly, steel is inherently resistant to pests such as termites and other wood-destroying organisms. This resilience translates into a reduced need for chemical treatments and less frequent maintenance, appealing to environmentally conscious consumers.

In recent years, metal sheds have gained immense popularity across various property types, from suburban homes to rural estates. These versatile structures offer a range of benefits that make them essential for homeowners and businesses alike. Whether used for storage, workshops, or even as hobby spaces, metal sheds provide a practical and durable solution that can enhance any property.