china slurry pump impeller type factories

Latest articles

Applications of Rubber Lined Slurry Pumps

china slurry pump impeller type factories...

china slurry pump impeller type factories 【china slurry pump impeller type factories】

Read MoreFor example.

china slurry pump impeller type factories...

china slurry pump impeller type factories 【china slurry pump impeller type factories】

Read MoreSlurry Pump

china slurry pump impeller type factories...

china slurry pump impeller type factories 【china slurry pump impeller type factories】

Read MoreAier is pumping experts and offer some useful tips to maintain your >slurry pump.

china slurry pump impeller type factories...

china slurry pump impeller type factories 【china slurry pump impeller type factories】

Read MoreDredge Pump Features

china slurry pump impeller type factories...

china slurry pump impeller type factories 【china slurry pump impeller type factories】

Read MoreFollow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

china slurry pump impeller type factories...

china slurry pump impeller type factories 【china slurry pump impeller type factories】

Read MoreMagnetite mixing

china slurry pump impeller type factories...

china slurry pump impeller type factories 【china slurry pump impeller type factories】

Read MoreDredge Pump

china slurry pump impeller type factories...

china slurry pump impeller type factories 【china slurry pump impeller type factories】

Read MoreThe concept of the , slurry pump, and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

china slurry pump impeller type factories...

china slurry pump impeller type factories 【china slurry pump impeller type factories】

Read MoreHow much solids damage can the customer tolerate?

china slurry pump impeller type factories...

china slurry pump impeller type factories 【china slurry pump impeller type factories】

Read More

Popular articles

- Slurry pump considerations

- Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

- Submersible Slurry Pump

- A , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

- Consideration should be given to installing mixers on guide rods in the catch basin/tank to keep solids in suspension and avoid settling in the catch basin/tank. When investing in a slurry pump, you want to pump slurry that includes solids, not just dirty water. Therefore, it is important to make sure that the pump is doing this; by using an agitator, the pump is fed with solids and pumping the slurry.

- Carbon transfer

Latest articles

-

Dry Installation

-

Slurry pump power adjustment

-

Aier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

-

For more information about this new and improved pump, please contact us.

-

- Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

-

What is the best seal arrangement for the application?

Links

In conclusion, the industrial bag closing machine head is an essential component of modern manufacturing and packaging processes. With its ability to enhance efficiency, provide consistent sealing, offer versatility across different bag types, reduce waste, and ensure user-friendly operation, it represents an investment in quality and reliability. As industries continue to evolve and demand greater productivity, the importance of these machine heads will only grow, making them integral to the success of packaging operations worldwide. By integrating high-quality industrial bag closing machine heads into their production lines, manufacturers can not only improve their operational efficiency but also enhance the overall quality of their products, ultimately leading to customer satisfaction and business growth.

2. Needle Compatibility The ability to use different needle sizes is crucial. A thicker needle can penetrate dense fabrics without breaking or bending, ensuring clean stitches and a successful project.

- Budget Heavy-duty machines come in a range of prices. Determine your budget before researching models to find one that offers the best value for your needs.

4. Cost-Effective Although the initial investment in an industrial overlocker may be higher than a standard sewing machine, the long-term benefits, including reduced labor costs and improved fabric usage, can lead to significant savings.

industrial overlocker for sale

2. Better Durability The double stitching not only looks appealing but also provides a stronger seam. This added strength is particularly useful in areas that experience a lot of stress, such as armholes and waistlines in garments.

Conclusion

what is the best computerized long arm quilting machine. Look for a machine that offers a wide range of quilting patterns and designs, as well as adjustable tension settings and an easy-to-use interface. Some machines also come with additional accessories such as quilting rulers, bobbin winders, and needle threaders, which can make the quilting process easier and more enjoyable.

what is the best computerized long arm quilting machine. Look for a machine that offers a wide range of quilting patterns and designs, as well as adjustable tension settings and an easy-to-use interface. Some machines also come with additional accessories such as quilting rulers, bobbin winders, and needle threaders, which can make the quilting process easier and more enjoyable.In conclusion, automatic bag closer machines play an essential role in the packaging industry by enhancing efficiency, ensuring product quality, and contributing to cost savings. As industries continue to evolve and demand higher productivity, these machines will remain vital tools for manufacturers. Investing in automatic bag closer technology is not just a matter of operational convenience; it is a strategic move towards achieving sustainable growth and meeting the ever-increasing expectations of consumers.

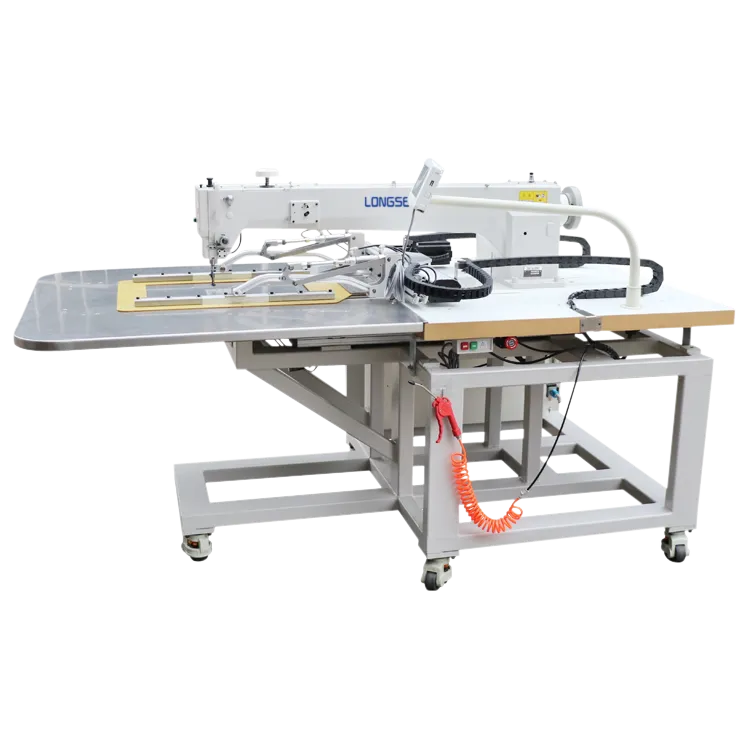

Larger Working Surface

Creating Pintucks and Tucks

what is twin needle sewing used for

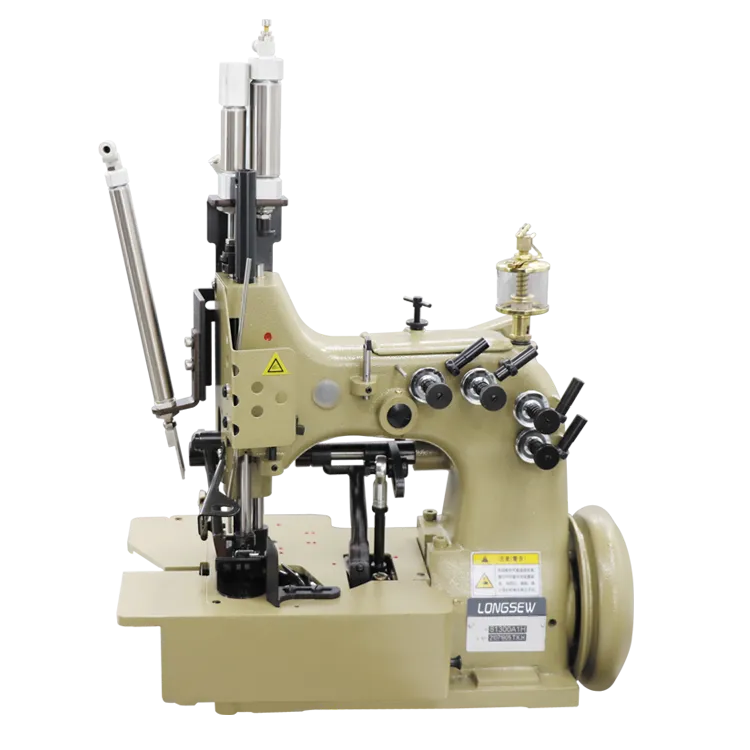

What is a Five Thread Overlock Machine?

In the realm of sewing, particularly for leatherwork, the choice of the machine can make all the difference in achieving professional-quality results. One of the best options for leather sewing enthusiasts and professionals alike is the walking foot leather sewing machine. Known for its robust design and unique feeding mechanism, this type of sewing machine offers unparalleled benefits when it comes to crafting items from thick or slippery materials.

Advantages of Using a Walking Foot Machine for Leather

When it comes to performance, the CB2500 does not disappoint. Its powerful motor enables smooth and consistent stitching at various speeds, catering to the preferences of different users. The machine’s ability to handle multiple layers of fabric without skipping stitches is particularly noteworthy, making it suitable for both lightweight and heavy materials.

In the world of furniture design, the importance of quality upholstery cannot be overstated. The comfort, aesthetic appeal, and durability of a sofa largely depend on the materials used and the expert craftsmanship involved in its construction. One critical component that significantly influences these factors is the sofa upholstery sewing machine. This specialized equipment has revolutionized the way sofas are manufactured, providing both efficiency and precision in the upholstery process.

In conclusion, an overlocker is an invaluable tool for anyone serious about sewing. Its ability to create durable, clean finishes on a variety of fabrics sets it apart from traditional sewing machines. Whether you are sewing garments for personal use or undertaking more substantial projects, investing in an overlocker can greatly improve the quality and efficiency of your work. With time and practice, you’ll find that this machine not only enhances your sewing skills but also opens up new creative possibilities.

In the world of manufacturing and textile production, CNC (Computer Numerical Control) machine sewing has emerged as a revolutionary technology that enhances precision, efficiency, and creativity. The integration of computer technology into sewing machinery has transformed traditional sewing processes, making them faster and more accurate than ever before. This article explores the evolution of CNC machine sewing, its benefits, and its implications for the future of the textile industry.

Exploring the Benefits of Sewing Machines with Built-in Walking Feet

3. Ease of Unraveling Unlike some other sewing techniques, lock stitches are less prone to unraveling. If a seam does begin to come apart, it will generally do so at a much slower rate than other stitch types, allowing for easier repairs.