heavy duty sewage pump manufacturer

Latest articles

To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

heavy duty sewage pump manufacturer...

heavy duty sewage pump manufacturer 【heavy duty sewage pump manufacturer】

Read MoreHow Slurry Pumps Differ From Standard Pumps?

heavy duty sewage pump manufacturer...

heavy duty sewage pump manufacturer 【heavy duty sewage pump manufacturer】

Read MoreLight-duty Slurry Pump

heavy duty sewage pump manufacturer...

heavy duty sewage pump manufacturer 【heavy duty sewage pump manufacturer】

Read More>Slurry Pump

heavy duty sewage pump manufacturer...

heavy duty sewage pump manufacturer 【heavy duty sewage pump manufacturer】

Read More>Slurry Pump vs Mud Pump

heavy duty sewage pump manufacturer...

heavy duty sewage pump manufacturer 【heavy duty sewage pump manufacturer】

Read MoreDredge Pump

heavy duty sewage pump manufacturer...

heavy duty sewage pump manufacturer 【heavy duty sewage pump manufacturer】

Read MoreCorrosiveness of the slurry

heavy duty sewage pump manufacturer...

heavy duty sewage pump manufacturer 【heavy duty sewage pump manufacturer】

Read MoreA variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

heavy duty sewage pump manufacturer...

heavy duty sewage pump manufacturer 【heavy duty sewage pump manufacturer】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

heavy duty sewage pump manufacturer...

heavy duty sewage pump manufacturer 【heavy duty sewage pump manufacturer】

Read MoreSlurry Pump Impeller Type

heavy duty sewage pump manufacturer...

heavy duty sewage pump manufacturer 【heavy duty sewage pump manufacturer】

Read More

Popular articles

- >Dredge Pump

- One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

- If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

- In a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

- Slurry Pump Impeller Type

- There is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

Latest articles

-

of a thick consistency, and.

-

Slurry Pump

-

It is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

-

For pumping abrasive slurries, these types of pumps can also be made from specialised high-wear alloys. Hardened stainless steel is also a common choice for abrasive slurries.

-

Choosing The Right Slurry Pump For Your Application

-

If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

Molar mass: 412.23

Made Safe only allows titanium dioxide as part of sunscreen solutions and diaper creams; all titanium dioxide must be non-nanoparticle. Made Safe does not allow titanium dioxide in any other personal care or household products.

Titanium dioxide comes in the form of a white powder and is sometimes used in cosmetics to adjust a color to a lighter shade. This is also why it can produce a white cast.

The Scientific Committee on Consumer Safety (SCCS) warns against sprayable products and powders that may expose users’ lungs to titanium dioxide through inhalation (10).

Titanium dioxide has also been classified as a possible human carcinogen by the International Agency for Research on Cancer, which has caused concern about its use in food products. This classification, however, is currently based on limited evidence from animal studies that involved the inhalation of titanium dioxide particles that increased the risk of lung cancer.

As a food additive, titanium dioxide and its nanoparticles in particular have been associated with DNA damage and cell mutations, which in turn, have potential to cause cancer. When used as a food coloring, it is known as E171.

best rutile titanium dioxide tio2 supplier.

Titanium dioxide is a food additive that can be found in over 3,000 different products in EWG’s Food Scores database.

Results and discussion

Lomon, one of the leading titanium dioxide manufacturers in China, produces the R996 grade titanium dioxide with purity levels exceeding 99%. This high purity ensures that the pigment provides excellent hiding power and color retention in paints, making it a popular choice for the paint industry.

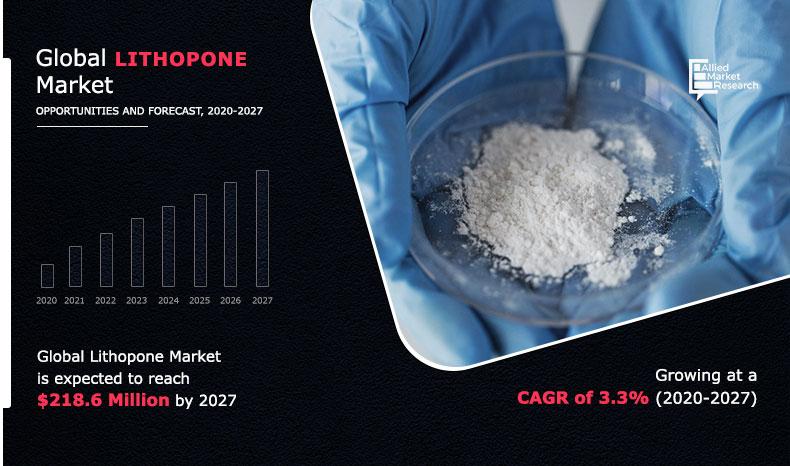

Lithopone: an alternative to titanium dioxide