china portable submersible slurry pump suppliers

Latest articles

Determine the operating parameters of the pump.

china portable submersible slurry pump suppliers...

china portable submersible slurry pump suppliers 【china portable submersible slurry pump suppliers】

Read MoreIt is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

china portable submersible slurry pump suppliers...

china portable submersible slurry pump suppliers 【china portable submersible slurry pump suppliers】

Read More>Dredge Pump

china portable submersible slurry pump suppliers...

china portable submersible slurry pump suppliers 【china portable submersible slurry pump suppliers】

Read MoreAs wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

china portable submersible slurry pump suppliers...

china portable submersible slurry pump suppliers 【china portable submersible slurry pump suppliers】

Read Moretarget=_blank>Slurry Pump

china portable submersible slurry pump suppliers...

china portable submersible slurry pump suppliers 【china portable submersible slurry pump suppliers】

Read MoreConsider the pump components

china portable submersible slurry pump suppliers...

china portable submersible slurry pump suppliers 【china portable submersible slurry pump suppliers】

Read MoreWe know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

china portable submersible slurry pump suppliers...

china portable submersible slurry pump suppliers 【china portable submersible slurry pump suppliers】

Read MoreThere are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

china portable submersible slurry pump suppliers...

china portable submersible slurry pump suppliers 【china portable submersible slurry pump suppliers】

Read More>Slurry Pump

china portable submersible slurry pump suppliers...

china portable submersible slurry pump suppliers 【china portable submersible slurry pump suppliers】

Read Moreof a thick consistency, and.

china portable submersible slurry pump suppliers...

china portable submersible slurry pump suppliers 【china portable submersible slurry pump suppliers】

Read More

Popular articles

- WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

- A target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

- Pumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

- Traditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

- When slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

- It is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

Latest articles

-

Larger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

-

target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

-

Typical Applications of slurry pump

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

-

- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

-

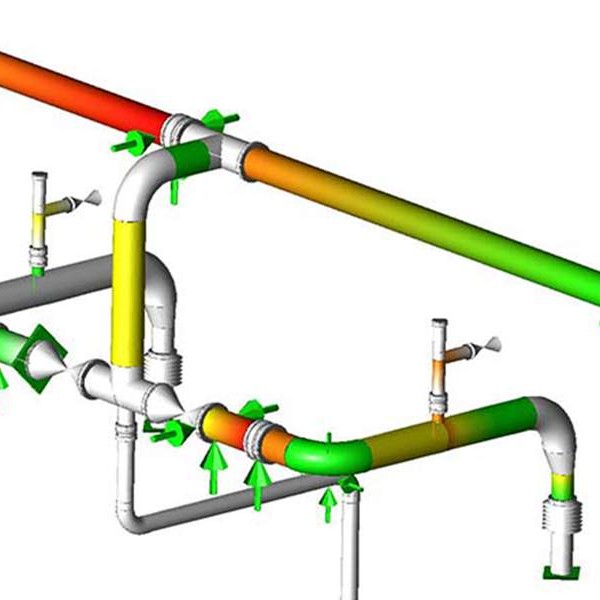

The Company Adopts Advanced Computer Aided Engineering Software

Links

- Fiberglass percentage: 70%, Resin Mix: 30%

- In conclusion, GRP tanks are an excellent choice for storing liquids in a wide range of industries due to their corrosion resistance, durability, versatility, and cost-effectiveness. Whether you need to store water, chemicals, or other liquids, a GRP tank can provide a reliable and long-lasting storage solution that will meet your needs for years to come.

- Rock well drilling is an essential process in the exploration and extraction of natural resources, particularly oil and gas, as well as for geological studies and groundwater access. It involves the creation of deep boreholes into the Earth's crust using specialized equipment and techniques.

- However, the role of coal drill bits extends beyond mere excavation. They are instrumental in promoting sustainable mining practices. By facilitating efficient drilling, they minimize waste, reduce the environmental impact of mining operations, and contribute to the responsible extraction of this finite resource.

- Precautions

- From an environmental perspective, fiberglass reinforced pipe aligns with sustainable practices. Its manufacturing process is less energy-intensive compared to other materials, and its durability reduces the demand for raw materials by extending the lifespan of pipelines. Furthermore, should a pipe reach the end of its service life, it can be recycled, reducing landfill waste.

- Fiberglass insulation tanks are typically made by winding glass fibers around a cylindrical mold. The glass fibers are coated with a resin, which is then cured at high temperatures to harden the material. This process results in a strong, lightweight, and durable tank that can withstand various environmental conditions.

Additionally, the use of compressed air allows for a cleaner working environment, as no oil or fuel emissions are produced Additionally, the use of compressed air allows for a cleaner working environment, as no oil or fuel emissions are produced

Additionally, the use of compressed air allows for a cleaner working environment, as no oil or fuel emissions are produced Additionally, the use of compressed air allows for a cleaner working environment, as no oil or fuel emissions are produced

This makes it an attractive option for budget-conscious projects looking to maximize value without compromising on quality This makes it an attractive option for budget-conscious projects looking to maximize value without compromising on quality

This makes it an attractive option for budget-conscious projects looking to maximize value without compromising on quality This makes it an attractive option for budget-conscious projects looking to maximize value without compromising on quality Fiberglass, on the other hand, is highly resistant to corrosion and can withstand exposure to these harsh chemicals without any significant degradation Fiberglass, on the other hand, is highly resistant to corrosion and can withstand exposure to these harsh chemicals without any significant degradation

Fiberglass, on the other hand, is highly resistant to corrosion and can withstand exposure to these harsh chemicals without any significant degradation Fiberglass, on the other hand, is highly resistant to corrosion and can withstand exposure to these harsh chemicals without any significant degradation

The lightweight nature of fiberglass reduces structural load on buildings, especially when installed on rooftops, minimizing potential safety risks The lightweight nature of fiberglass reduces structural load on buildings, especially when installed on rooftops, minimizing potential safety risks

The lightweight nature of fiberglass reduces structural load on buildings, especially when installed on rooftops, minimizing potential safety risks The lightweight nature of fiberglass reduces structural load on buildings, especially when installed on rooftops, minimizing potential safety risks They do not support combustion and produce minimal smoke, ensuring safety in case of a fire emergency They do not support combustion and produce minimal smoke, ensuring safety in case of a fire emergency

They do not support combustion and produce minimal smoke, ensuring safety in case of a fire emergency They do not support combustion and produce minimal smoke, ensuring safety in case of a fire emergency