high quality submersible pump for slurry factory

Latest articles

Selecting a dredge pump

high quality submersible pump for slurry factory...

high quality submersible pump for slurry factory 【high quality submersible pump for slurry factory】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

high quality submersible pump for slurry factory...

high quality submersible pump for slurry factory 【high quality submersible pump for slurry factory】

Read MoreHow Slurry Pumps Differ From Standard Pumps?

high quality submersible pump for slurry factory...

high quality submersible pump for slurry factory 【high quality submersible pump for slurry factory】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our

high quality submersible pump for slurry factory...

high quality submersible pump for slurry factory 【high quality submersible pump for slurry factory】

Read MoreAs new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

high quality submersible pump for slurry factory...

high quality submersible pump for slurry factory 【high quality submersible pump for slurry factory】

Read More>Slurry Pump

high quality submersible pump for slurry factory...

high quality submersible pump for slurry factory 【high quality submersible pump for slurry factory】

Read MoreSlurry Pump

high quality submersible pump for slurry factory...

high quality submersible pump for slurry factory 【high quality submersible pump for slurry factory】

Read MoreLarger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

high quality submersible pump for slurry factory...

high quality submersible pump for slurry factory 【high quality submersible pump for slurry factory】

Read MoreThe slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

high quality submersible pump for slurry factory...

high quality submersible pump for slurry factory 【high quality submersible pump for slurry factory】

Read MoreTo reduce wear, reduce the pump discharge pressure to the lowest possible point.

high quality submersible pump for slurry factory...

high quality submersible pump for slurry factory 【high quality submersible pump for slurry factory】

Read More

Popular articles

- The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

- In this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

- Slurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

- Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

- Pumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

- A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

Latest articles

-

- By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

-

The same point of slurry pump and mud pump

-

There is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

-

It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

-

The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

-

Metal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

Links

Even big manufacturers such as Cuisinart have shifted much of their skillet production to China. One approach to finding out where a skillet came from is to look underneath.

- In conclusion, the National Cast Iron Skillet is not merely a kitchen implement; it's a culinary journey, a connection to the past, and an investment in the future. It embodies the spirit of resilience, tradition, and the joy of slow, thoughtful cooking. Whether you're searing a steak to perfection or baking a golden cornbread, each meal cooked in this skillet carries a story, a flavor, and a legacy that only a National Cast Iron Skillet can provide. So, let it be your trusty companion on your gastronomic adventures, and witness how it transforms not just your food, but your entire cooking experience.

- The secret to the Big Bacon Press's success lies in its design. The press features a heavy-duty construction that ensures even pressure is applied to each slice of bacon. This results in perfectly cooked bacon with a crisp exterior and a juicy interior. The non-stick surface also means that the bacon releases easily, making clean-up a breeze.

- New Skillet Pan A Must-Have Kitchen Essential

- These design features make skillets (frying pans) perfect utensils for flipping, shallow frying, stir-frying, high-heat searing, or grilling meat at high temperatures.

- Beyond the monetary value, owning a sizzling tray has its non-tangible benefits. It can inspire creativity in the kitchen, encouraging cooks to experiment with different ingredients and techniques. Moreover, it adds a touch of excitement to dinner parties, turning ordinary meals into memorable dining experiences.

- Next, apply a thin, even layer of oil to the pan. You can use any type of oil, but oils with high smoke points, such as vegetable or canola oil, are ideal for this purpose. Use a paper towel or brush to spread the oil evenly across the bottom and sides of the pan.

- One of the key advantages of using a heavy cast iron skillet is its ability to retain heat. When cooking with this pan, you can be sure that the heat will be distributed evenly across the bottom of the pan, resulting in perfectly cooked food every time. Whether you're frying, sautéing, or even baking, the heavy cast iron skillet will provide consistent results.

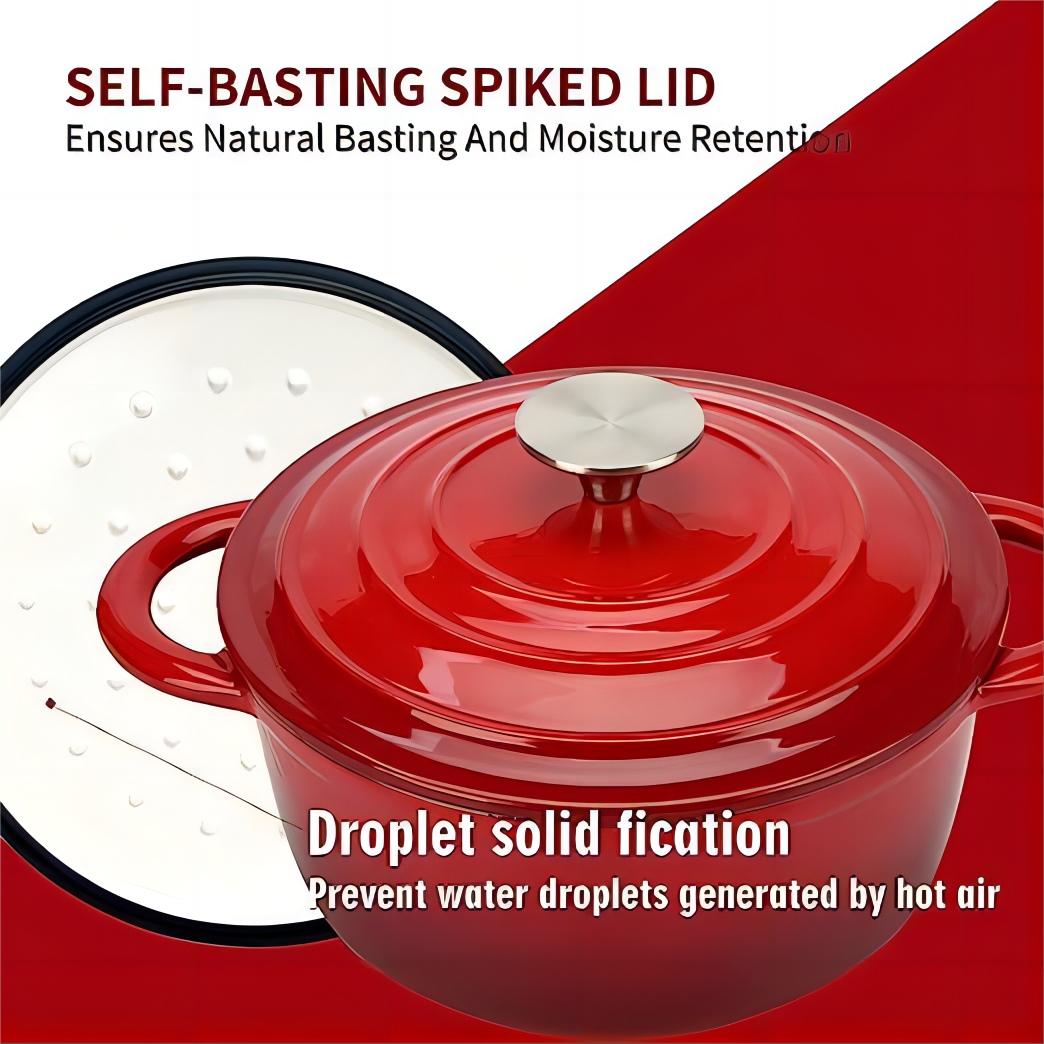

Hearty and Flavorful Meals: Dutch ovens are perfect for creating hearty and flavorful meals such as stews, soups, roasts, and casseroles. Their ability to maintain a consistent temperature and seal in moisture results in tender and succulent dishes.

two sided griddle. The flat side of the griddle is perfect for cooking foods that need to be cooked evenly, such as pancakes or eggs. The ridged side, on the other hand, is great for grilling meats and creating those coveted grill marks. By being able to adjust the heat on each side independently, you can ensure that your food is cooked to perfection every time.

Ultimately, the type of frying pan you choose will depend on your individual cooking style, needs, and preferences. No matter which type you choose, a quality frying pan is an essential kitchen tool that will provide you with years of cooking enjoyment.

History Of The Frying Pan

outdoor griddle cast iron. This means that they can go from stovetop to table, making them perfect for serving meals directly from the grill. The heat retention also allows you to cook foods at a lower temperature, which helps to preserve the natural flavors and nutrients in your ingredients.

outdoor griddle cast iron. This means that they can go from stovetop to table, making them perfect for serving meals directly from the grill. The heat retention also allows you to cook foods at a lower temperature, which helps to preserve the natural flavors and nutrients in your ingredients.

Carl Schmidt Marburg Fry Pan Marble Non-Stick Coating 20cm

*When in doubt, just remember this: you can often perform the same cooking tasks in either a skillet or a sauté pan, but keep in mind that the angle of the sidewalls of each pan differ, which means that one might be better suited than the other for certain cooking tasks.*

Ceramic pans are also light in weight and cannot be subjected to high heat. They shouldn't be used with metallic utensils and can only be used on a stovetop.