high quality drainage pump manufacturers

Latest articles

Light-duty Slurry Pump

high quality drainage pump manufacturers...

high quality drainage pump manufacturers 【high quality drainage pump manufacturers】

Read MoreAll manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

high quality drainage pump manufacturers...

high quality drainage pump manufacturers 【high quality drainage pump manufacturers】

Read MoreStep 2

high quality drainage pump manufacturers...

high quality drainage pump manufacturers 【high quality drainage pump manufacturers】

Read MoreA slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

high quality drainage pump manufacturers...

high quality drainage pump manufacturers 【high quality drainage pump manufacturers】

Read MoreIf a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

high quality drainage pump manufacturers...

high quality drainage pump manufacturers 【high quality drainage pump manufacturers】

Read MorePacking the box seal

high quality drainage pump manufacturers...

high quality drainage pump manufacturers 【high quality drainage pump manufacturers】

Read MoreWhen dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

high quality drainage pump manufacturers...

high quality drainage pump manufacturers 【high quality drainage pump manufacturers】

Read More- transport solids hydraulically

high quality drainage pump manufacturers...

high quality drainage pump manufacturers 【high quality drainage pump manufacturers】

Read MoreMany types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

high quality drainage pump manufacturers...

high quality drainage pump manufacturers 【high quality drainage pump manufacturers】

Read MoreIncludes a large number of solids or particles.

high quality drainage pump manufacturers...

high quality drainage pump manufacturers 【high quality drainage pump manufacturers】

Read More

Popular articles

- Selecting And Operating A Slurry Pump

- Light-duty Slurry Pump

- Some quench seals are planned to replace the tight fitting outlet restriction with a secondary seal and a top outlet that can be piped to capture the used quench fluid and drain it from the rotating assembly. However the principle is the same, we try to cool the seal rather than flush it in any way.

- If centrifugal, are the impellers of the right design and material?

- A slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

Latest articles

-

A slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

-

Slurry Pump

-

Light-duty Slurry Pump

-

Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

-

What is a dredging pump?

-

Slurry Pump

Links

In conclusion, chrome sewing machine needles are an excellent choice for any sewing project. With their enhanced durability, smooth glide, and variety of types, they can make the sewing process more enjoyable and efficient. By understanding their benefits, selecting the appropriate type for your sewing needs, and practicing proper care, you can achieve exceptional results in all your sewing endeavors. Whether you're a beginner or an experienced seamstress, investing in quality chrome needles is a decision that will enhance your sewing experience.

One of the most critical factors to consider is the motor power of the sewing machine. Machines with stronger motors can handle thicker fabrics more efficiently. Look for machines that have at least a 1.0-1.5 amp motor. These machines tend to have more robust performance and can sew through multiple layers of fabric without faltering.

One of the key advantages of automatic template sewing machines is their ability to handle complex patterns that would be exceedingly time-consuming and difficult to replicate by hand. For example, garments featuring elaborate embroidery or detailed appliqué can now be produced swiftly and efficiently. This not only saves time but also reduces labor costs, making it an attractive option for manufacturers looking to maximize their resources.

Benefits of Using a Compound Feed Heavy Duty Sewing Machine

- Convenient drop-in bobbin

Conclusion

4. Capacity to Handle Heavy Materials Leather is known for its resistance and thickness, which can be a challenge for many sewing machines. Manual leather sewing machines are often designed with robust mechanisms that can handle the heft of leather without jamming or breaking needles. This capability makes them ideal for crafting a wide range of leather products.

Conclusion

Double needle sewing machines allow for a variety of decorative stitching techniques that can add a unique touch to leather items. The parallel lines of stitching not only reinforce seams but also enhance the aesthetic quality of the finished product. This capability is particularly beneficial for high-end leather goods, where visual appeal is as important as functionality. The option to choose different needle sizes and thread colors further expands creative possibilities, making it easier for artisans to personalize their creations.

We only recommend things we love. If you buy something through our site, we might earn a commission.

Size and Portability

Sustainability is another significant benefit of these machines. With the increasing awareness of environmental issues, the textile industry is under pressure to adopt more sustainable practices. Automatic template sewing machines contribute to this goal by enhancing fabric utilization. By accurately cutting fabric and minimizing waste, these machines help reduce the environmental footprint of textile production.

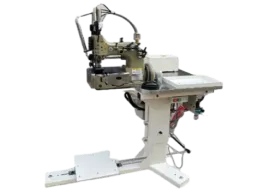

automatic template sewing machine

Types of Chrome Sewing Machine Needles

In conclusion, investing in a heavy-duty quilting sewing machine can transform your quilting journey. With its robust features designed for durability and efficiency, you can create stunning quilts with ease. Whether you are a novice or an experienced quilter, the right heavy-duty machine will help you realize your creative visions and produce beautiful, lasting masterpieces.

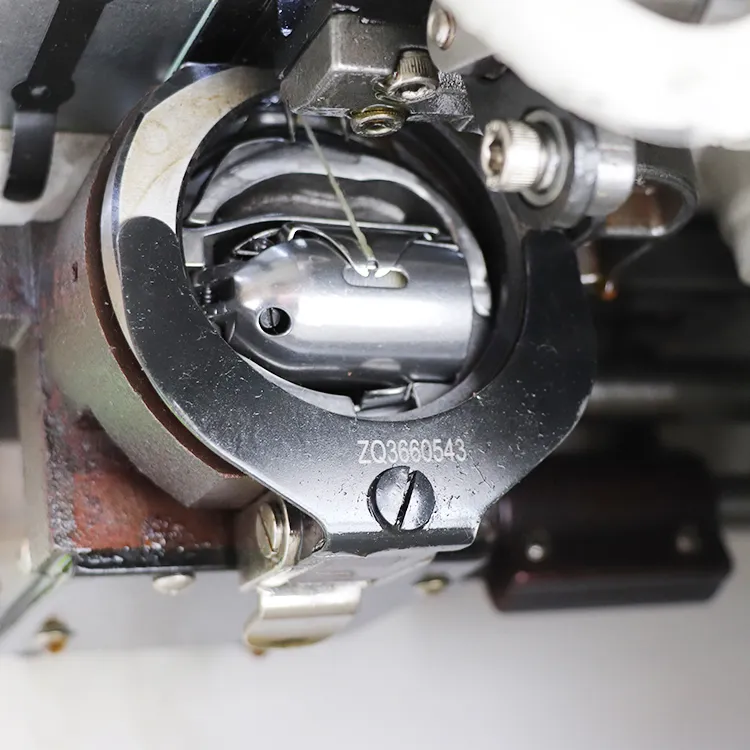

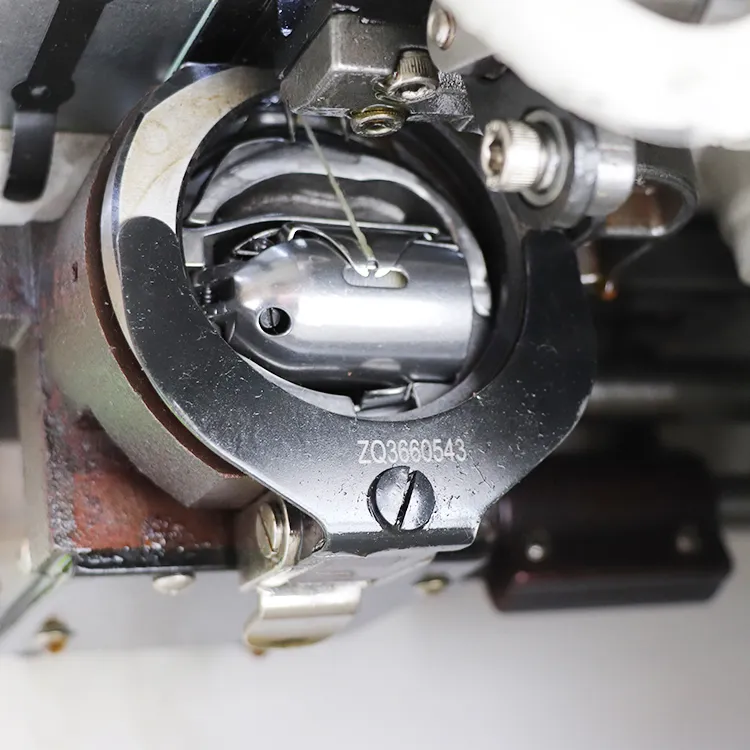

The lockstitch sewing machine is an essential piece of equipment in the textile industry, renowned for its efficiency and versatility. Its operation is fundamental to modern garment manufacturing, providing a durable and reliable stitch that is crucial for constructing clothing and other fabric-based products.

3. Larger Work Area The long arm feature allows users to work on bigger projects without feeling cramped. Whether it’s quilts, draperies, or large fashion pieces, the extra space facilitates smoother maneuvering of the fabric, thus minimizing errors.

double needle long arm sewing machine

Versatility in Stitching

Quality control is another crucial aspect of shirt manufacturing that automatic sewing machines enhance. These machines are designed to deliver uniformity across all garments, ensuring that each shirt adheres to the same high standards. By eliminating the variability inherent in manual sewing, manufacturers can produce shirts that fit better and exhibit superior construction. This consistency not only boosts customer satisfaction but also strengthens brand reputation.

The zigzag stitch, a staple in sewing, expands the possibilities of what you can create. Unlike straight stitches, zigzag stitches can stretch, making them ideal for knit fabrics and for areas that require flexibility, like armholes and waistbands. Additionally, zigzag stitches can be used for decorative purposes and finishing edges to prevent fraying. The ability to switch between zigzag and straight stitches means that the long arm heavy duty zigzag sewing machine can adapt to various sewing techniques, allowing for delicate embellishments or sturdy seams as needed.

Eco-Friendly Practices

In conclusion, the double needle chain stitch sewing machine is an invaluable tool that enhances sewing capabilities through its unique design and functionality. Its ability to create strong, elastic seams while providing an eye-catching finish makes it a preferred choice for both industrial and home sewers. With continued advancements in technology, the importance of such machines in the textile industry will only grow, solidifying their place in modern sewing practices. Whether in a factory or a home workshop, the double needle chain stitch sewing machine stands as a testament to the evolution of sewing technology, driving innovation and creativity in garment production.

For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric

For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric For instance, the jeans needle, also known as the denim needle, is a popular choice for sewing through multiple layers of thick fabric heavy duty sewing needle. The universal needle, on the other hand, is versatile and can handle a range of fabrics, including some heavy-duty ones.

heavy duty sewing needle. The universal needle, on the other hand, is versatile and can handle a range of fabrics, including some heavy-duty ones.3. Versatility Modern bag closing machine heads are designed to handle a variety of bag types and sizes. This versatility makes them suitable for different industries, accommodating everything from small sachets to large bulk bags. Manufacturers can easily adapt their packaging lines to meet changing market demands without needing to invest in entirely new systems.

Boat upholstery is not just about style; it needs to withstand a variety of challenging conditions. Marine environments expose fabrics to moisture, sunlight, salt, and wear over time. Therefore, the materials used for boat upholstery—such as vinyl, canvas, and outdoor fabrics—are designed to be both aesthetically pleasing and highly durable. In this context, the sewing machine you select must be capable of handling these heavy-duty fabrics effectively.

What Does a Computerized Sewing Machine Do?

Moreover, the color and pattern of the jumbo belt can significantly affect the overall outfit. A classic black or brown belt offers timeless elegance, while a bold pattern or vibrant color can serve as a focal point, drawing attention and showcasing personal style. The flexibility in styling ensures that jumbo belts can appeal to a broad audience, making them a must-have accessory in any fashion enthusiast's collection.

Applications in the Industry

In conclusion, when considering the purchase of a portable bag closer machine, it's essential to evaluate your specific needs and the nature of your operations. While price is a significant factor, it should also be weighed against quality, durability, available features, and potential long-term savings. Investing in a reliable portable bag closer machine can enhance operational efficiency and ultimately lead to greater profitability in your business endeavors. Whether you are a small business or a large-scale manufacturer, careful consideration of these factors can lead to a well-informed purchase decision.

An overlock machine, often referred to as a serger, is a specialized sewing machine designed to create seam finishes and provide a clean, professional look to garments. Unlike conventional sewing machines, overlock machines can sew and trim fabric edges simultaneously, preventing fraying and ensuring durability. They are widely used in the apparel industry for hems, cuffs, and seams, especially in knit fabrics.

The single needle stitch, often hailed as one of the fundamental techniques in sewing and embroidery, epitomizes precision and craftsmanship. Rooted in centuries of tradition, this method has transcended time, finding relevance in both contemporary fashion and classic artisanal workmanship. While sewing might seem like a simple task to some, the single needle stitch embodies a level of detail and finesse that can elevate any fabric creation.

In the world of carpet manufacturing and retail, efficiency and quality are paramount. One of the essential tools for ensuring a high-quality finish and durability in carpet production is the carpet overlocking machine. As the demand for professional-looking carpets continues to rise, the need for advanced overlocking machines has become increasingly significant. This article will explore what carpet overlocking machines are, their benefits, and what to consider when looking for one for sale.

However, the double needle price reflects the complexities inherent in implementing this technique. The machinery required for double needle stitching is more advanced and costly than standard single needle machines. This initial investment can be a deterrent for smaller manufacturers or those operating on tight budgets. Moreover, the operation of double needle machines often requires skilled labor, further increasing production costs. Manufacturers must strike a balance between investing in quality production techniques and maintaining competitive pricing.

double needle price

The regular sewing machine has been designed to sew together thinner fabrics, like clothes or bags. However, the thicker the fabric becomes, the harder the machine is forced to work. This means that regular machines might struggle to sew together more solid fabric items, like curtains. In this area, you will be better off purchasing a heavy-duty machine. Because their motor is more powerful, you will be able to get through these thicker materials without overworking your engine.

Moreover, the integration of CNC technology in stitching machines enhances the overall sustainability of textile production. CNC machines reduce fabric waste through precise cutting and stitching, allowing manufacturers to optimize material usage. This waste reduction not only decreases costs but also lessens the environmental impact of textile manufacturing, aligning with the industry's growing focus on sustainability and ethical production practices.

5. Bed Size and Construction

Industrial sewing machines can use a lot of energy, especially computerized ones. Select sewing machines that won't overload your circuits when using one in a residential setting. Industrial machines tend to require upwards of 430 watts per hour or more.Generally, people start running into problems when running multiple heavy-duty sewing machines on one power circuit or when using multiple machines off of a single power strip. Before setting up your sewing room, consider the wattage (stickers can be found on most machines) and check with your electrician to ensure you will not be blowing fuses or creating fire hazards. Do you live off the grid and use solar or battery to power your electronics? In that case, you may need to purchase an inverter to configure the right electrical current to avoid causing permanent damage to your motor and other electrical components inside your sewing machine.