high quality warman froth pump factories

Latest articles

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

high quality warman froth pump factories...

high quality warman froth pump factories 【high quality warman froth pump factories】

Read MoreIf you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

high quality warman froth pump factories...

high quality warman froth pump factories 【high quality warman froth pump factories】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

high quality warman froth pump factories...

high quality warman froth pump factories 【high quality warman froth pump factories】

Read MoreMany types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

high quality warman froth pump factories...

high quality warman froth pump factories 【high quality warman froth pump factories】

Read MoreIf you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

high quality warman froth pump factories...

high quality warman froth pump factories 【high quality warman froth pump factories】

Read MoreAIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

high quality warman froth pump factories...

high quality warman froth pump factories 【high quality warman froth pump factories】

Read More1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

high quality warman froth pump factories...

high quality warman froth pump factories 【high quality warman froth pump factories】

Read MoreSlurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

high quality warman froth pump factories...

high quality warman froth pump factories 【high quality warman froth pump factories】

Read MoreSlurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

high quality warman froth pump factories...

high quality warman froth pump factories 【high quality warman froth pump factories】

Read Morereduce the discharge pressure of the pump to the lowest possible point, and.

high quality warman froth pump factories...

high quality warman froth pump factories 【high quality warman froth pump factories】

Read More

Popular articles

- Vertical Slurry Pump

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

- >Slurry Pump

- >Slurry Pump

- 2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

Latest articles

-

The terms slurry pump and dredge pump can be used interchangeably.

-

Slurry Pump

-

Dredge Pump Features

-

WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

-

>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

-

of a thick consistency, and.

Links

Primary Functions of a Control Box

Bike Connect is still in development, and its creators are working on adding features that will allow cyclists to use it without looking at their phones. (And, we have to ask—what’s stopping someone in a car from using this?) But it’s a great example of what some crafty technology geeks can do with a few wires, capacitors and a durable outdoor electronics enclosure.

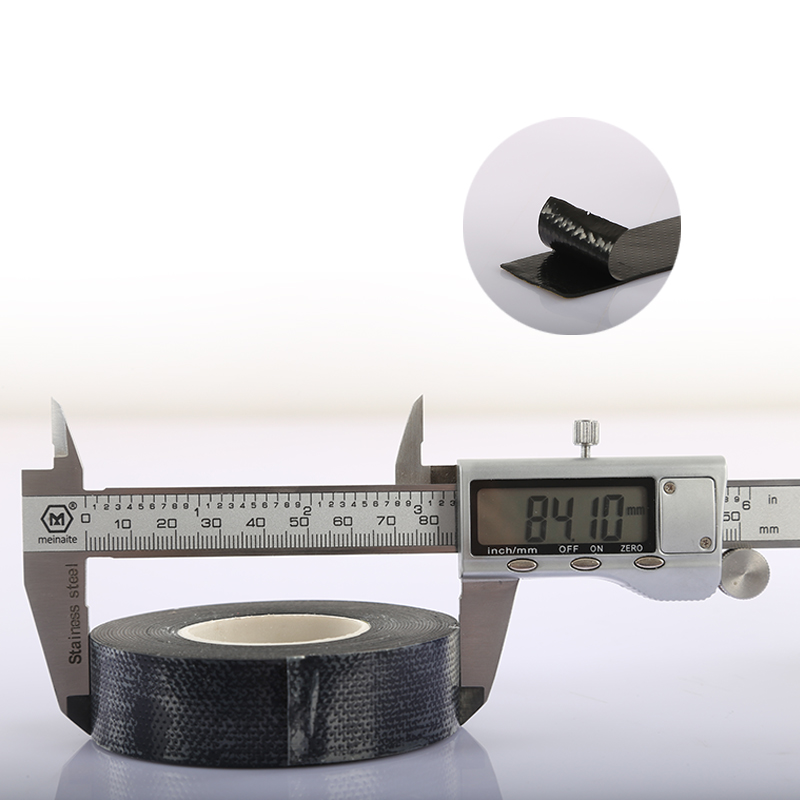

XF-FR110 Flame retardant Automotive WireHarness PVC Tape is a PVC film produced by using DOP as plasticizer and coated with high-performance pressure-sensitive good insulation, voltage adhesive, with resistance, cold resistance, and other characteristics. Comply with ROHS directive.

4. Neoprene Rubber Tape: Neoprene rubber tape is a versatile material that is suitable for a wide range of applications. It is known for its resistance to heat, oil, and chemicals, which makes it ideal for automotive and industrial applications.

Vulcanizing Tape is a type of self-fusing rubber tape that adheres to itself without the need for an adhesive. This unique property allows the tape to create a watertight and airtight seal when wrapped around an object. It's often utilized for electrical insulation, plumbing repairs, and automotive applications. The tape is resistant to extreme temperatures, UV exposure, and various chemicals, making it exceptionally durable in diverse environments.

Electrical:Butyl sealant tape can be employed to seal and insulate electrical connections and cable joints, to help prevent the ingress of water and other contaminants.

You can also find many more in-depth studies of what makes a good control box online. They’ll help you get a good idea of how to design component spacing, wireways and more. Next up, we’ll take a look at what some of the different types of control boxes look like and how they function.

This means that it can withstand exposure to moisture without losing its adhesion, making it an excellent choice for outdoor projects or situations where moisture may be present This means that it can withstand exposure to moisture without losing its adhesion, making it an excellent choice for outdoor projects or situations where moisture may be present

This means that it can withstand exposure to moisture without losing its adhesion, making it an excellent choice for outdoor projects or situations where moisture may be present This means that it can withstand exposure to moisture without losing its adhesion, making it an excellent choice for outdoor projects or situations where moisture may be present flex tape mini black. Whether you're working in the garden or repairing a leaky roof, Flex Tape Mini Black will keep your project secure.

flex tape mini black. Whether you're working in the garden or repairing a leaky roof, Flex Tape Mini Black will keep your project secure. Moreover, its color-coded options facilitate easy identification of different wire types, contributing to improved organization and safety in electrical installations Moreover, its color-coded options facilitate easy identification of different wire types, contributing to improved organization and safety in electrical installations

Moreover, its color-coded options facilitate easy identification of different wire types, contributing to improved organization and safety in electrical installations Moreover, its color-coded options facilitate easy identification of different wire types, contributing to improved organization and safety in electrical installations self adhesive pvc insulation tape.

self adhesive pvc insulation tape. In warehouses, it helps to organize inventory by creating defined zones, improving efficiency in stock management and reducing the risk of accidents In warehouses, it helps to organize inventory by creating defined zones, improving efficiency in stock management and reducing the risk of accidents

In warehouses, it helps to organize inventory by creating defined zones, improving efficiency in stock management and reducing the risk of accidents In warehouses, it helps to organize inventory by creating defined zones, improving efficiency in stock management and reducing the risk of accidents yellow black marking tape.

yellow black marking tape.Rubber Electrical Tape. Pads, Helps Protect and Insulate up to 69kV.

This tape comes in eight colors:

Here are some specific things that control box can do:

For instance, stainless steel can resist corrosion, while polycarbonate may be chosen for its non-conductive properties.

Silicone self-adhesive tape is a remarkable product that can revolutionize the way you approach repairs and DIY projects. Its unique properties, durability, and versatility make it an invaluable addition to your toolkit. From plumbing emergencies to automotive fixes, this tape offers a quick and reliable solution.

The short answer is no, but the long answer is a bit more complicated.

It can be used to mark social distancing measures, queuing systems, and designated zones for specific activities It can be used to mark social distancing measures, queuing systems, and designated zones for specific activities

It can be used to mark social distancing measures, queuing systems, and designated zones for specific activities It can be used to mark social distancing measures, queuing systems, and designated zones for specific activities floor marking tape. The ease of application and removal allows for quick adaptation to changing guidelines and protocols.

floor marking tape. The ease of application and removal allows for quick adaptation to changing guidelines and protocols.Furthermore, its affordability makes it a cost-effective solution for electrical insulation. A modest investment can lead to significant safety and reliability improvements in electrical projects, emphasizing the importance of using quality materials.