high quality abrasives pump wastewater centrifugal pump

Latest articles

WA Heavy-duty Slurry Pump

high quality abrasives pump wastewater centrifugal pump...

high quality abrasives pump wastewater centrifugal pump 【high quality abrasives pump wastewater centrifugal pump】

Read MoreFloor drainage

high quality abrasives pump wastewater centrifugal pump...

high quality abrasives pump wastewater centrifugal pump 【high quality abrasives pump wastewater centrifugal pump】

Read MoreSlurry pump seals

high quality abrasives pump wastewater centrifugal pump...

high quality abrasives pump wastewater centrifugal pump 【high quality abrasives pump wastewater centrifugal pump】

Read MoreWith the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

high quality abrasives pump wastewater centrifugal pump...

high quality abrasives pump wastewater centrifugal pump 【high quality abrasives pump wastewater centrifugal pump】

Read MoreSlurry Pump VS Mud Pump

high quality abrasives pump wastewater centrifugal pump...

high quality abrasives pump wastewater centrifugal pump 【high quality abrasives pump wastewater centrifugal pump】

Read MoreOther manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

high quality abrasives pump wastewater centrifugal pump...

high quality abrasives pump wastewater centrifugal pump 【high quality abrasives pump wastewater centrifugal pump】

Read More- Keeping clean catch basins clean from solids

high quality abrasives pump wastewater centrifugal pump...

high quality abrasives pump wastewater centrifugal pump 【high quality abrasives pump wastewater centrifugal pump】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

high quality abrasives pump wastewater centrifugal pump...

high quality abrasives pump wastewater centrifugal pump 【high quality abrasives pump wastewater centrifugal pump】

Read MoreChoosing The Right Slurry Pump For Your Application

high quality abrasives pump wastewater centrifugal pump...

high quality abrasives pump wastewater centrifugal pump 【high quality abrasives pump wastewater centrifugal pump】

Read MoreSlurry pipe diameter.

high quality abrasives pump wastewater centrifugal pump...

high quality abrasives pump wastewater centrifugal pump 【high quality abrasives pump wastewater centrifugal pump】

Read More

Popular articles

- One problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

- Monitoring

- Traditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

- As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

- >Slurry Pump

- Determine the operating parameters of the pump.

Latest articles

-

If you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

-

factors-to-consider-when-choosing-a-slurry-pump

-

It is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

-

How to choose a slurry pump?

-

If centrifugal, are the impellers of the right design and material?

-

Some quench seals are planned to replace the tight fitting outlet restriction with a secondary seal and a top outlet that can be piped to capture the used quench fluid and drain it from the rotating assembly. However the principle is the same, we try to cool the seal rather than flush it in any way.

Links

- When using a cast iron griddle for the grill, it is important to properly season the griddle before use. Seasoning the griddle creates a protective layer that prevents food from sticking and enhances the flavor of your dishes. To season a cast iron griddle, simply coat the surface with a thin layer of oil and heat it on the grill until it begins to smoke. Repeat this process several times before using the griddle for cooking.

ANODIZED FRYING PANS

- The pre-seasoned Dutch oven is a versatile and essential kitchen tool that has been a staple in many households for generations. This type of pot is designed to withstand high temperatures and distribute heat evenly, making it perfect for a wide range of cooking methods, from searing and browning to slow-cooking and baking.

The geometry of a pan can affect how easily moisture is driven off of food, and how rapidly a sauce will reduce. It's often claimed that the sloped sides of a skillet help moisture exuded by cooking meats evaporate more rapidly, allowing you to sear more efficiently. And this is true, but only given the same cooking area. In other words, a 12-inch skillet with a 10-inch cooking area will sear foods more efficiently than a 10-inch sauté pan. The corollary to this, of course, is that, given an equal amount of food that needs searing over super-high heat (some steaks, for example), the large surface area of a sauté pan does not offer any significant advantages over a skillet—you'll still have to cook in just as many batches.

- When using a bacon press on a griddle, you simply place the press on top of the bacon as it cooks. The weight of the press helps to flatten the bacon strips, ensuring that they cook evenly and preventing them from curling up or cooking unevenly. This results in perfectly cooked bacon that is crispy and delicious, with no soggy or undercooked spots.

- Moreover, the small iron skillet pan lends itself beautifully to intimate meals and single-serving dishes. It's the perfect size for preparing a special breakfast for one or a small portion of a favorite stir-fry. Its petite dimensions ensure that your food is cooked to perfection without being crowded, preserving the integrity of flavors and textures.

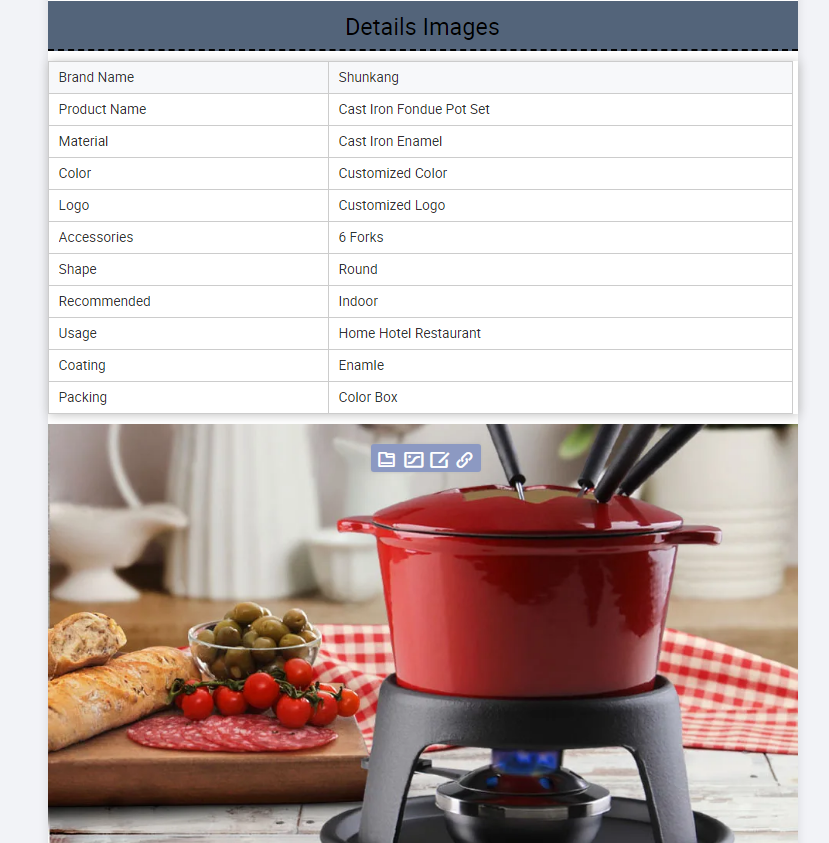

As demand surges for cookware that seamlessly blends functionality with aesthetic appeal, manufacturers have responded by crafting enameled cast iron cookware sets that marry tradition with modern design sensibilities. There are many Cast Iron Cookware Manufacturers, renowned for their commitment to quality and innovation.

cast iron with porcelain enamel cookware. The smooth and non-porous surface of the porcelain enamel coating makes it easy to clean and prevents food from sticking to the cookware. This means that you can cook with less oil or fat, resulting in healthier dishes and easier cleanup.

Previously the word skillet was mostly used for frying pans manufactured of cast iron. Saying skillet, people implied the one of this material. However, the phrase cast iron frying pan is also quite common. That is why the two terms have become interchangeable. Both skillets & frying pans refer to the same types of pan, and there is no need to look for features to distinguish between them.

So, both of them have:

And if you’re a fan of big breakfasts at brunch spots? A cast iron skillet will certainly come in handy to recreate an almost similar vibe. Lastly, outdoor enthusiasts who often spend time cooking outdoors will favour the versatility of the skillet as its indestructible nature allows you to easily carry it and cook outdoors.

Types Of Cast Iron Cookware

History Of The Frying Pan

black enamel cast iron cookware. It can be used on both stovetops and ovens, making it a great all-in-one solution for any chef. The cookware is also suitable for use on induction cooktops, which are becoming increasingly popular due to their efficiency and quick heating capabilities.

black enamel cast iron cookware. It can be used on both stovetops and ovens, making it a great all-in-one solution for any chef. The cookware is also suitable for use on induction cooktops, which are becoming increasingly popular due to their efficiency and quick heating capabilities.

Over time, this patina develops into a smooth, dark coating that is easy to clean and care for Over time, this patina develops into a smooth, dark coating that is easy to clean and care for

Over time, this patina develops into a smooth, dark coating that is easy to clean and care for Over time, this patina develops into a smooth, dark coating that is easy to clean and care for iron skillet grill pan.

iron skillet grill pan.Sauté pans, in contrast, have sides that meet the bottom surface at a right angle. This defined edge leaves the entire bottom of the pan even and flat, making for a much larger surface area. As compared to skillets of the same diameter, a 12-inch sauté pan has 12 inches of usable cooking surface. The sauté pan’s tall sides allow it to hold a greater volume of liquid than a skillet and help prevent spillovers.

Frying Pan

A sauté pan is better suited than a stockpot for holding liquids, reducing splashing, and cooking many foods at once. The biggest disadvantage of the sauté pan is its size. You’ll notice this since the 12-inch sauté pan is significantly larger than the skillet.