Custom Springs for Specific Needs

که تاسو د چرګانو د نټینګ اخیستلو پلان لرئ، غوره ده چې د بیلابیلو پلورونکو سره مشورې وکړئ، ترڅو د نرخونو او کیفیتونو په اړه معلومات تر لاسه کړئ. د آنلاین پلورونکي او محلي پلورونکي ترمنځ هم توپیرونه شته، نو د پلورونکي انتخاب له دې امله خورا مهم دی.

Engineers and designers must consider several factors when selecting small strong springs for their applications, including load requirements, environmental conditions, and fatigue limits. Choosing the right spring involves calculating the appropriate dimensions, material properties, and manufacturing methods. Advanced techniques, such as computer-aided design (CAD) and finite element analysis (FEA), allow for more accurate simulations, ensuring the springs meet the desired specifications.

Applications

In conclusion, cattle panels have proven to be an essential tool for anyone involved in livestock management. Their strength, adaptability, portability, and affordability make them ideal for creating secure environments for cattle. As the agricultural landscape continues to evolve, incorporating innovative tools like cattle panels can lead to improved management practices and ultimately contribute to better yielding and healthier livestock. For those interested in maximizing their cattle farming operations, understanding and utilizing cattle panels effectively is a step in the right direction.

The choice of spring material significantly influences its performance. While higher-grade materials might offer better fatigue resistance and longevity, they can also be more expensive. To strike the right balance between performance and cost, consider the specific requirements of your application. Evaluate factors such as load, cycle life, corrosion resistance, and environmental conditions to determine the most suitable material.

In addition to automotive engineering, double helical springs find their uses in various machinery and equipment, including industrial presses and vibration isolators

. In these contexts, the springs help manage forces and vibrations, thus protecting sensitive components from damage. Their ability to accommodate large displacements without permanent deformation ensures that machinery operates smoothly and efficiently, which is vital for productivity in manufacturing environments.double helical spring

RVS Grid Panel Een Duurzame Oplossing voor Diverse Toepassingen

Regarding mechanical systems, springs play a vital role in providing elasticity and absorbing shocks or vibrations. The regular and coil springs are two commonly used variations among the various types of springs available. This article will examine the differences between these two types of springs, their characteristics, and their applications.

Coils used on machined springs are square, rectangular (radial or longitudinal), and trapezoidal. Trapezoidal coils are common to springs used in lateral bending and lateral translation. The shape allows for the additional lateral motion without coil contact. The size of the coil is easily changed to fit the spring’s needs. No standard sizes apply.

Pink Craft Wire Mtengo Wapadera pa Zinthu Zanu za Manjaa

Gas springs exert force using nitrogen gas in a sealed cylinder. They can be customized for applications with specific requirements for stroke length, tonnage, and mounting options.

Other key benefits of using gas springs include:

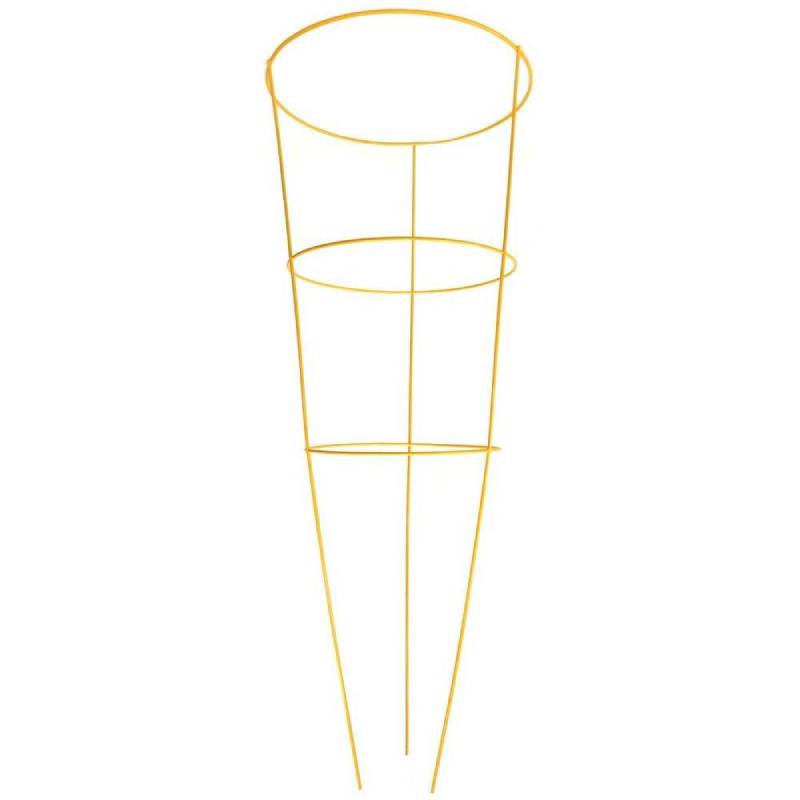

De plus, ces cages facilitent l'accès aux fruits et aux feuilles pour les soins et la récolte. Les jardiniers peuvent facilement inspecter les tomates, vérifier leur état de santé, et récolter les fruits sans trop de désagrément. Cette accessibilité est essentielle, surtout quand on sait que la récolte des tomates doit être effectuée régulièrement pour encourager la production continue.

Applications in Various Industries