oem medium head heavy duty slurry pump factory

Latest articles

Desire for higher efficiency than centrifugal pumps

oem medium head heavy duty slurry pump factory...

oem medium head heavy duty slurry pump factory 【oem medium head heavy duty slurry pump factory】

Read MoreIt is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

oem medium head heavy duty slurry pump factory...

oem medium head heavy duty slurry pump factory 【oem medium head heavy duty slurry pump factory】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

oem medium head heavy duty slurry pump factory...

oem medium head heavy duty slurry pump factory 【oem medium head heavy duty slurry pump factory】

Read MoreTo find out more about Aier slurry Pumps, please >contact us.

oem medium head heavy duty slurry pump factory...

oem medium head heavy duty slurry pump factory 【oem medium head heavy duty slurry pump factory】

Read MoreIt is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

oem medium head heavy duty slurry pump factory...

oem medium head heavy duty slurry pump factory 【oem medium head heavy duty slurry pump factory】

Read MoreCorrosiveness of the slurry

oem medium head heavy duty slurry pump factory...

oem medium head heavy duty slurry pump factory 【oem medium head heavy duty slurry pump factory】

Read MoreMany types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

oem medium head heavy duty slurry pump factory...

oem medium head heavy duty slurry pump factory 【oem medium head heavy duty slurry pump factory】

Read MoreDamage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

oem medium head heavy duty slurry pump factory...

oem medium head heavy duty slurry pump factory 【oem medium head heavy duty slurry pump factory】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

oem medium head heavy duty slurry pump factory...

oem medium head heavy duty slurry pump factory 【oem medium head heavy duty slurry pump factory】

Read MoreWL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

oem medium head heavy duty slurry pump factory...

oem medium head heavy duty slurry pump factory 【oem medium head heavy duty slurry pump factory】

Read More

Popular articles

- - By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

- - Pumping media where abrasive particles are present

- Dredge Pump Features

- Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

- Other manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

- Magnetite mixing

Latest articles

-

If a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

-

Consider the following.

-

Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

-

On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

-

We know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

-

The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

Links

- Overall, amalgamating tape is a handy and reliable tool that has a wide range of uses. Its flexibility, durability, and ease of use make it a popular choice for various applications. So next time you are faced with a repair or sealing job, reach for a roll of amalgamating tape and experience its magic for yourself.

In this article, we will explore the question: is electrical tape heat resistant?

heat tape electric.

What is a well pump control box and what does it do exactly? Continue reading to learn more.

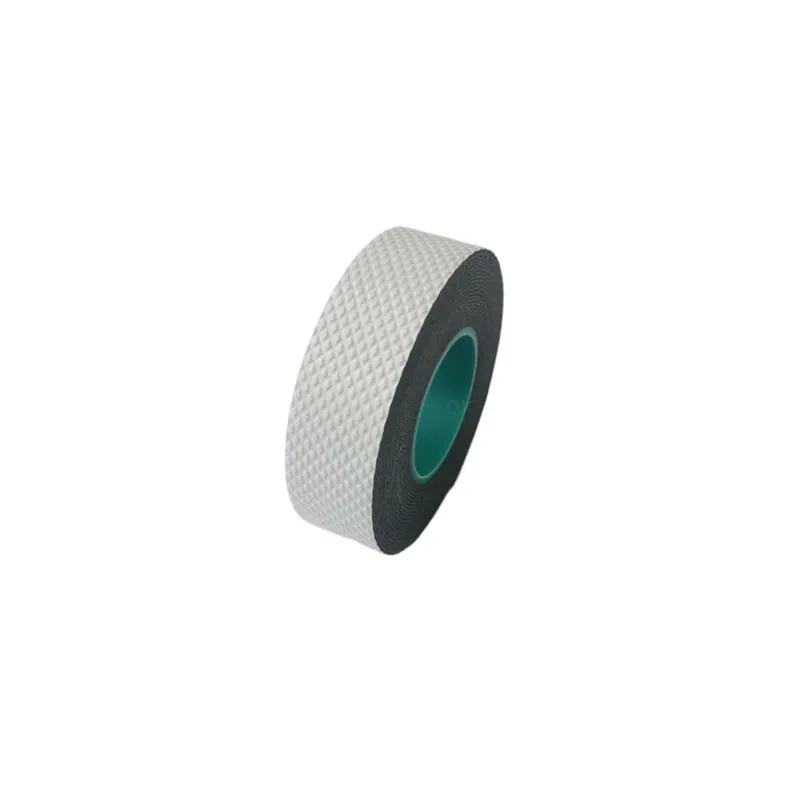

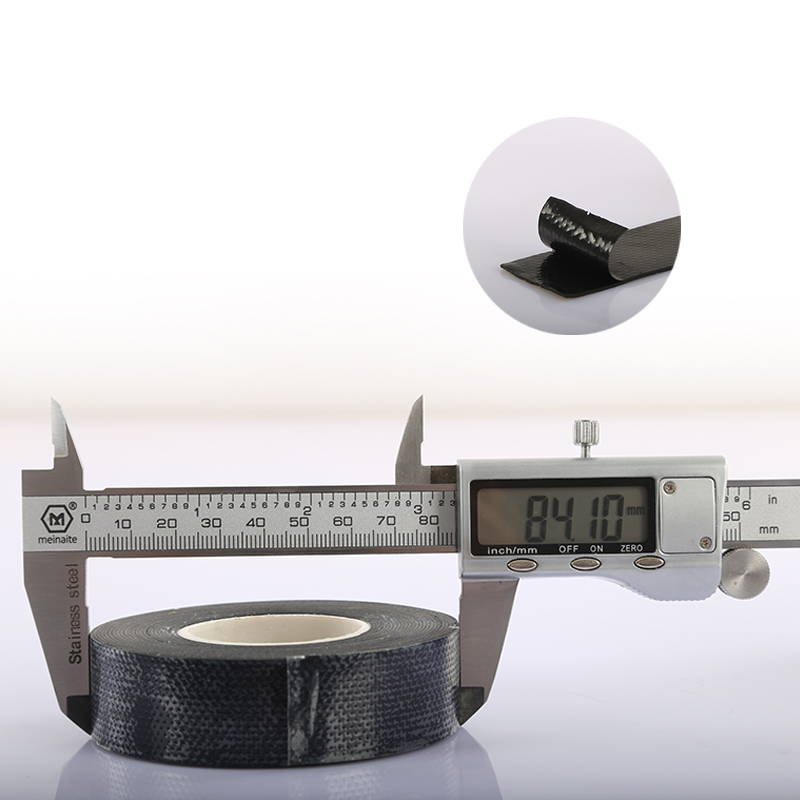

A versatile tape that can be used for everything from sealing pipes and hoses to general waterproofing and electrical cable splicing.

The tape is made from high-quality materials that provide resistance to abrasion and damage, ensuring that your repair lasts. Additionally, it is designed to withstand temperature fluctuations, remaining effective in sub-zero conditions as well as high heat. This makes it suitable for both indoor and outdoor projects, whether you are fixing a plumbing leak in the winter or protecting electrical connections in a hot engine compartment.

3m vulcanizing tape

Electricians have critical jobs. Keeping our world powered requires concentration, knowledge and skill. Some of the most dangerous work is done by electricians working on medium and high voltage applications. Ethylene propylene and silicone rubber electrical tapes have the highest dielectric rating of electrical tapes made by 3M and are a trusted product in the toolbox of most medium and high voltage linemen and installers. With proper wrapping, their self-fusing properties help to eliminate voids in critical areas that may cause catastrophic failures .

In addition to its ease of use, self-adhesive electrical tape is also highly durable

. It can withstand high temperatures, making it suitable for use in a variety of environments. Whether you are working in a hot attic or a cold basement, this tape will hold up under extreme conditions.self adhesive electrical tape

At the heart of the problem is that even in highly bike-friendly cities like Portland, stop lights aren’t timed for the speed or cadence of the average person riding a bike. That can create unpleasant situations in traffic and even danger for cyclists—so the creators of Bike Connect set out to do something about it.

Inexpensive, incredibly effective and easy to use, it remains flexible in both intense heat and freezing cold and resists breakdown in extreme temperature variations.

Seal out moisture from electrical connections

PVC insulation tape uses

black electrical insulation tape. Electricians often use it to color-code different circuits or mark specific wires for future reference, enhancing the overall clarity and efficiency of electrical systems. The strong adhesive backing guarantees that once applied, the tape will stay in place, surviving vibrations and environmental changes without peeling off or losing stickiness.

black electrical insulation tape. Electricians often use it to color-code different circuits or mark specific wires for future reference, enhancing the overall clarity and efficiency of electrical systems. The strong adhesive backing guarantees that once applied, the tape will stay in place, surviving vibrations and environmental changes without peeling off or losing stickiness. self vulcanizing tape. It is employed to repair and protect pipes, tanks, and other structures from corrosion and damage. The tape's ability to adhere tightly to various surfaces, even in the presence of moisture or extreme temperatures, makes it an invaluable asset for contractors and maintenance personnel.

self vulcanizing tape. It is employed to repair and protect pipes, tanks, and other structures from corrosion and damage. The tape's ability to adhere tightly to various surfaces, even in the presence of moisture or extreme temperatures, makes it an invaluable asset for contractors and maintenance personnel.The power supply unit links your control box to your main supply or power source. It also ensures that the power comes within the ideal current and voltage ranges thereby protecting your linked devices.

The applications of fireproof gasket tape are vast and varied. In the automotive industry, for example, it is used to seal exhaust systems and improve overall vehicle safety. In the aerospace sector, it helps create fireproof barriers in various components, ensuring the safety of both passengers and crew. The construction industry benefits from this tape by utilizing it to insulate and protect electrical systems in buildings, minimizing fire risks in residential and commercial properties.

In an era where safety and efficiency are paramount, especially in industrial applications, fireproof gasket tape has emerged as a critical component for ensuring both these aspects. This specially designed adhesive tape is engineered to withstand high temperatures and mitigate fire risks, making it an invaluable asset in various sectors such as manufacturing, automotive, aerospace, and construction.