casting slurry pump part manufacturer

Latest articles

Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

casting slurry pump part manufacturer...

casting slurry pump part manufacturer 【casting slurry pump part manufacturer】

Read MoreMetal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

casting slurry pump part manufacturer...

casting slurry pump part manufacturer 【casting slurry pump part manufacturer】

Read MoreSlurry pump seals

casting slurry pump part manufacturer...

casting slurry pump part manufacturer 【casting slurry pump part manufacturer】

Read MoreSlurry Pump

casting slurry pump part manufacturer...

casting slurry pump part manufacturer 【casting slurry pump part manufacturer】

Read More2. All have vertical pumps and horizontal pumps and can convey slurry.

casting slurry pump part manufacturer...

casting slurry pump part manufacturer 【casting slurry pump part manufacturer】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

casting slurry pump part manufacturer...

casting slurry pump part manufacturer 【casting slurry pump part manufacturer】

Read MoreIt is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

casting slurry pump part manufacturer...

casting slurry pump part manufacturer 【casting slurry pump part manufacturer】

Read Morehow-does-a-dredge-pump-work

casting slurry pump part manufacturer...

casting slurry pump part manufacturer 【casting slurry pump part manufacturer】

Read MoreThe concentration of solids in the slurry - measured as a percentage of the total volume.

casting slurry pump part manufacturer...

casting slurry pump part manufacturer 【casting slurry pump part manufacturer】

Read MoreWhat is slurry?

casting slurry pump part manufacturer...

casting slurry pump part manufacturer 【casting slurry pump part manufacturer】

Read More

Popular articles

- Choosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

- When dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

- The slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

- If centrifugal, are the impellers of the right design and material?

- Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

- testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

Latest articles

-

Slurry Pump

-

Slurry Pump

-

Aier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

-

Safety

-

Pumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

-

Slurry pump considerations

Links

Wrinkle-resistant, affordable and easy to maintain, but not particularly elegant, jersey sheets are a great bedroom idea for teenagers or kids room idea.

- Tips for Choosing the Right Lightweight Duvet Insert

- Furthermore, hospital bed sheets can also serve as a medium for non-verbal communication. The state of the sheets can indicate a patient's condition to medical staff. Tucked-in sheets can signal a well-cared-for patient, while untidy sheets might suggest the need for attention.

- When selecting a heavy duvet insert, consider factors such as your personal warmth preference, climate, and any potential allergies. For instance, if you live in a cooler region, a high-fill-power down duvet might be perfect. However, if you're sensitive to allergens, a hypoallergenic synthetic option could be a better choice.

- The world of bedding design is vast and diverse, ranging from minimalist chic to bold and vibrant patterns. The choice of bedding can set the tone for the entire bedroom, impacting its ambiance and visual appeal. A crisp white duvet, for instance, exudes simplicity and sophistication, while a brightly colored quilt can infuse a room with energy and playfulness.

- Thread count is another crucial factor. Generally, a higher thread count signifies a softer and more durable sheet. However, it's essential to note that quality trumps quantity; sheets with a blend of high-quality fibers at a moderate thread count often provide the perfect balance of softness and durability.

High-thread-count sheets are made from stronger, finer yarns that resist pilling and wear over time High-thread-count sheets are made from stronger, finer yarns that resist pilling and wear over time

High-thread-count sheets are made from stronger, finer yarns that resist pilling and wear over time High-thread-count sheets are made from stronger, finer yarns that resist pilling and wear over time 1800 thread count sheets good. As a result, your investment in these superior sheets will stand the test of time, offering years of exceptional use without losing their sumptuous feel.

1800 thread count sheets good. As a result, your investment in these superior sheets will stand the test of time, offering years of exceptional use without losing their sumptuous feel.

Thread count is another important factor to consider when choosing high-quality bedding. 300-count bedding is considered the highest quality, offering a balance of comfort and durability. However, it's important to note that higher thread counts don't always guarantee better quality. In addition to thread count, the type of fabric and weave must also be considered to ensure that the high-quality bedding is to your liking.

When it comes to towels, one size does not fit all. There are different sizes of towels available to suit different needs and preferences, so it's important to choose the right size for your specific requirements. Large towels, medium towels, full towels, and regular towels all serve different purposes and are designed to meet a variety of needs.

Technology

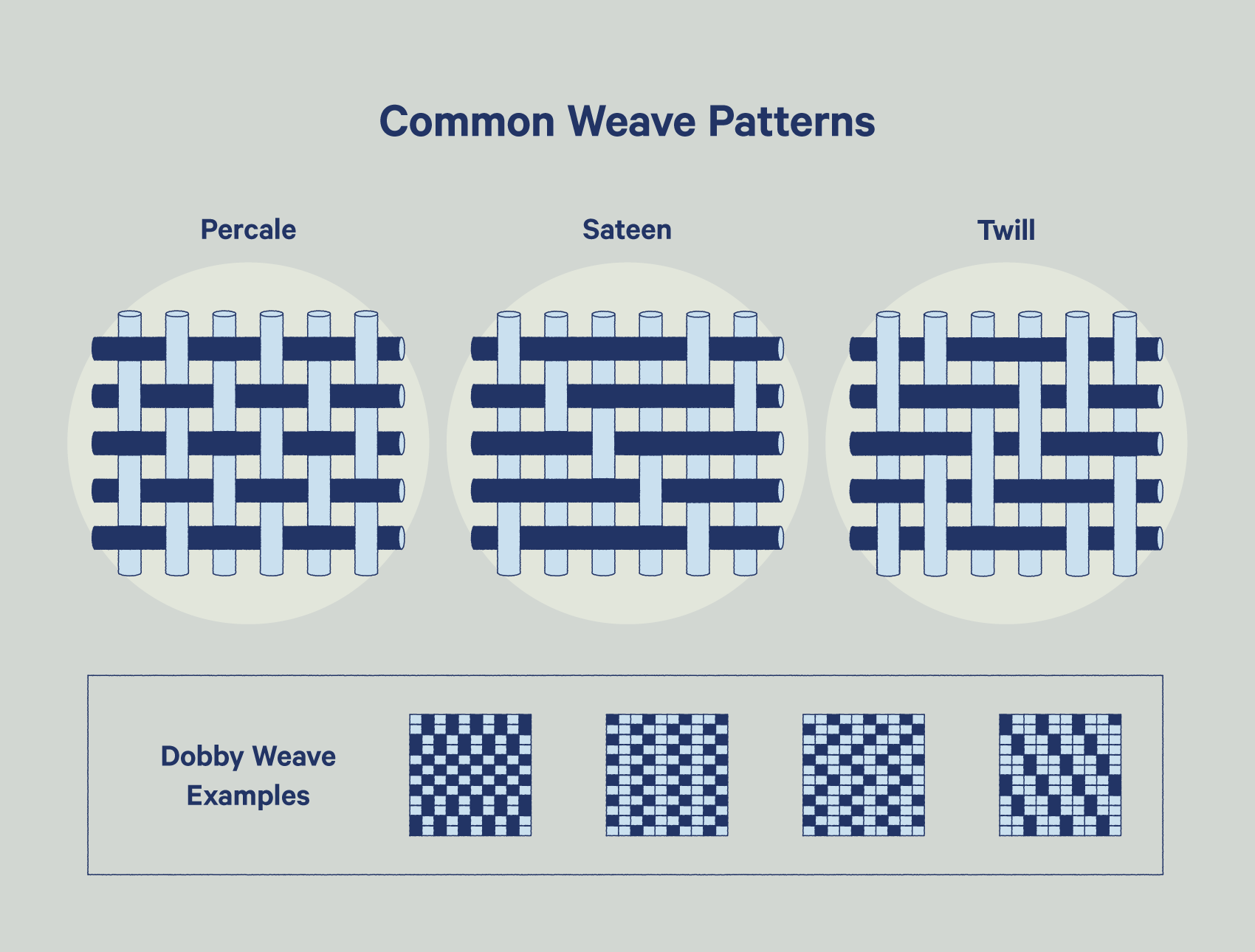

Sateen

In addition, the extra width provides more room for experimentation with draping, gathering, or pleating, adding depth and dimension to the final product In addition, the extra width provides more room for experimentation with draping, gathering, or pleating, adding depth and dimension to the final product

In addition, the extra width provides more room for experimentation with draping, gathering, or pleating, adding depth and dimension to the final product In addition, the extra width provides more room for experimentation with draping, gathering, or pleating, adding depth and dimension to the final product extra wide material.

extra wide material.Percale Sheets

Moreover, they can be easily removed and washed, maintaining hygiene and freshness Moreover, they can be easily removed and washed, maintaining hygiene and freshness

Moreover, they can be easily removed and washed, maintaining hygiene and freshness Moreover, they can be easily removed and washed, maintaining hygiene and freshness cot quilt insert.

cot quilt insert.