vertical sump pump drawing manufacturers

Latest articles

Again, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

vertical sump pump drawing manufacturers...

vertical sump pump drawing manufacturers 【vertical sump pump drawing manufacturers】

Read MoreLess downtime

vertical sump pump drawing manufacturers...

vertical sump pump drawing manufacturers 【vertical sump pump drawing manufacturers】

Read MoreKeep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

vertical sump pump drawing manufacturers...

vertical sump pump drawing manufacturers 【vertical sump pump drawing manufacturers】

Read MoreUnder ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

vertical sump pump drawing manufacturers...

vertical sump pump drawing manufacturers 【vertical sump pump drawing manufacturers】

Read MoreSettling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

vertical sump pump drawing manufacturers...

vertical sump pump drawing manufacturers 【vertical sump pump drawing manufacturers】

Read MoreChoosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

vertical sump pump drawing manufacturers...

vertical sump pump drawing manufacturers 【vertical sump pump drawing manufacturers】

Read MoreAny type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

vertical sump pump drawing manufacturers...

vertical sump pump drawing manufacturers 【vertical sump pump drawing manufacturers】

Read Moretarget=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

vertical sump pump drawing manufacturers...

vertical sump pump drawing manufacturers 【vertical sump pump drawing manufacturers】

Read MoreStep 2

vertical sump pump drawing manufacturers...

vertical sump pump drawing manufacturers 【vertical sump pump drawing manufacturers】

Read MoreWhat is the optimum seal arrangement for the application?

vertical sump pump drawing manufacturers...

vertical sump pump drawing manufacturers 【vertical sump pump drawing manufacturers】

Read More

Popular articles

- Materials of Construction

- Choosing The Right Slurry Pump For Your Application

- Dredge Pump

- Slurry pipe diameter.

- Aier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

- target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

Latest articles

-

To reduce wear, reduce the pump discharge pressure to the lowest possible point.

-

Quenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

-

Pumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

Links

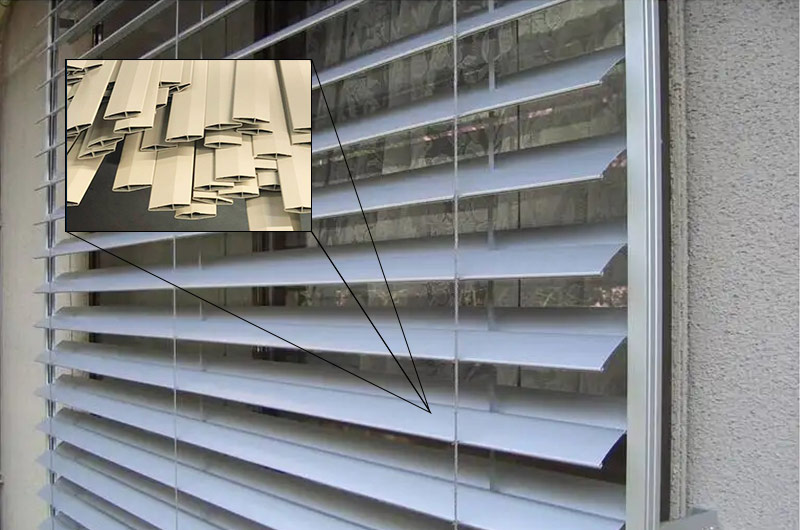

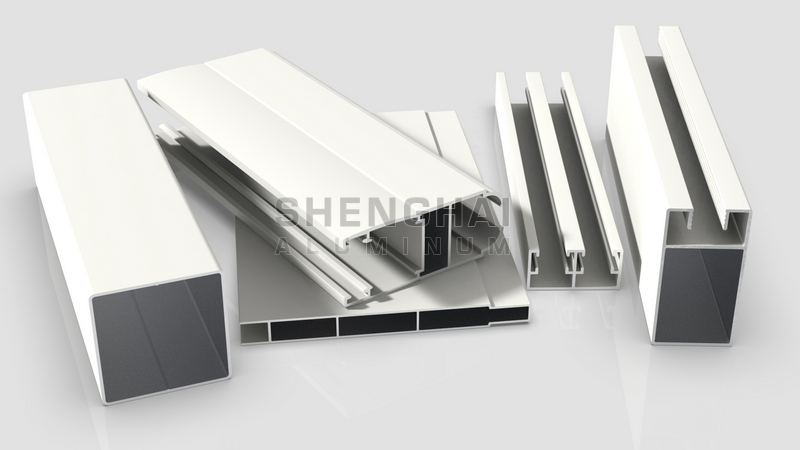

Anodised Aluminium Profiles

2. The craftsmanship

This aluminum grade is an alloy of silicon and magnesium. It offers excellent machinability properties and is usually extruded and cold-worked.

aluminium glass frame profile. Their powder-coated finishes provide a durable and weather-resistant surface that is easy to clean and maintain, ensuring that the frames will continue to look sharp and new for many years to come.

To give you an idea of how unreliable iron is, Bronze Age civilizations actually knew about iron. Iron is actually the fourth most abundant element in the Earth’s crust. It was just that iron was so prone to breaking that Bronze Age civilizations preferred bronze, an alloy of copper and tin, two much less common elements. The ancient Greeks would sail to Britain—literally going to England in a rowboat—to get the tin.

Aluminium extrusion profiles find a wide range of applications in the windows segment, offering numerous benefits to both residential and commercial projects. One of the primary uses of these profiles is in the construction of window frames. The flexibility of aluminium extrusion allows for the creation of slim, lightweight yet strong frames that maximize the glass area, providing unobstructed views and ample natural light.

Sliding door rollers come in various designs and materials, specifically tailored to meet different requirements. The most common types include

Ornamental cast iron panels are more than just decorative elements; they are a testament to the artistry and innovation of historical craftsmanship. Their blend of beauty and strength makes them a valuable addition to any design scheme. Whether incorporated into a residential property, a public park, or commercial architecture, these panels continue to enchant and inspire. As architects and designers increasingly appreciate the unique charm of ornamental cast iron, they remain a timeless choice that enchants both the eye and the spirit. The allure of cast iron will undoubtedly persist, creating beautiful spaces that honor the past while embracing the future.

Shipment:

iron gate parts. A well-designed latch ensures the gate stays securely shut, while a robust lock adds an extra layer of protection. There are various types, including padlocks, mortise locks, and electronic keypads, each offering different levels of security and convenience.

iron gate parts. A well-designed latch ensures the gate stays securely shut, while a robust lock adds an extra layer of protection. There are various types, including padlocks, mortise locks, and electronic keypads, each offering different levels of security and convenience.Members or rails are horizontal elements that make up some main structural components of iron fences. These components are important for your fencing as they essentially help to hold the fence together. Rails run parallel to the ground and exist to connect fence panels to the posts. Additional horizontal members may be a part of the fence’s design in order to incorporate decorative elements or panels into your wrought iron fence.

Aluminum alloy window is made of aluminum alloy architectural profiles, frame, fan structure of the window, divided into ordinary aluminum alloy doors and windows and broken aluminum alloy doors and windows. Aluminum alloy window is beautiful, sealed and high strength. It is widely used in the field of architectural engineering. In the home decoration, aluminum alloy doors and windows are commonly used to seal the balcony.

Quality Standards

Energy Efficiency

Aesthetic Appeal

Cast iron, like wrought iron, typically has a black color; however, cast iron may be painted or chemically colored to achieve a wide range of colors. Silver and gray are the most popular color choices, although many other tones are often available.