best pump for slurry manufacturer

Latest articles

The selection of a dredge or , slurry pump, can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

best pump for slurry manufacturer...

best pump for slurry manufacturer 【best pump for slurry manufacturer】

Read MoreKeep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

best pump for slurry manufacturer...

best pump for slurry manufacturer 【best pump for slurry manufacturer】

Read MoreSlurry Pump

best pump for slurry manufacturer...

best pump for slurry manufacturer 【best pump for slurry manufacturer】

Read MoreWA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

best pump for slurry manufacturer...

best pump for slurry manufacturer 【best pump for slurry manufacturer】

Read MorePumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

best pump for slurry manufacturer...

best pump for slurry manufacturer 【best pump for slurry manufacturer】

Read MoreMud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

best pump for slurry manufacturer...

best pump for slurry manufacturer 【best pump for slurry manufacturer】

Read MoreSlurry pump construction materials

best pump for slurry manufacturer...

best pump for slurry manufacturer 【best pump for slurry manufacturer】

Read MoreThe size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

best pump for slurry manufacturer...

best pump for slurry manufacturer 【best pump for slurry manufacturer】

Read MoreSlurry pipe diameter.

best pump for slurry manufacturer...

best pump for slurry manufacturer 【best pump for slurry manufacturer】

Read MoreStep 4

best pump for slurry manufacturer...

best pump for slurry manufacturer 【best pump for slurry manufacturer】

Read More

Popular articles

- target=_blank>Slurry Pump

- Step 4

- 1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

- Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

- If a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

- Traditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

Latest articles

-

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

-

To reduce wear, reduce the pump discharge pressure to the lowest possible point.

-

Compared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

-

Although the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

-

If the exact in-pump viscosity of the product is unknown, CSI can help

-

Aier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

Links

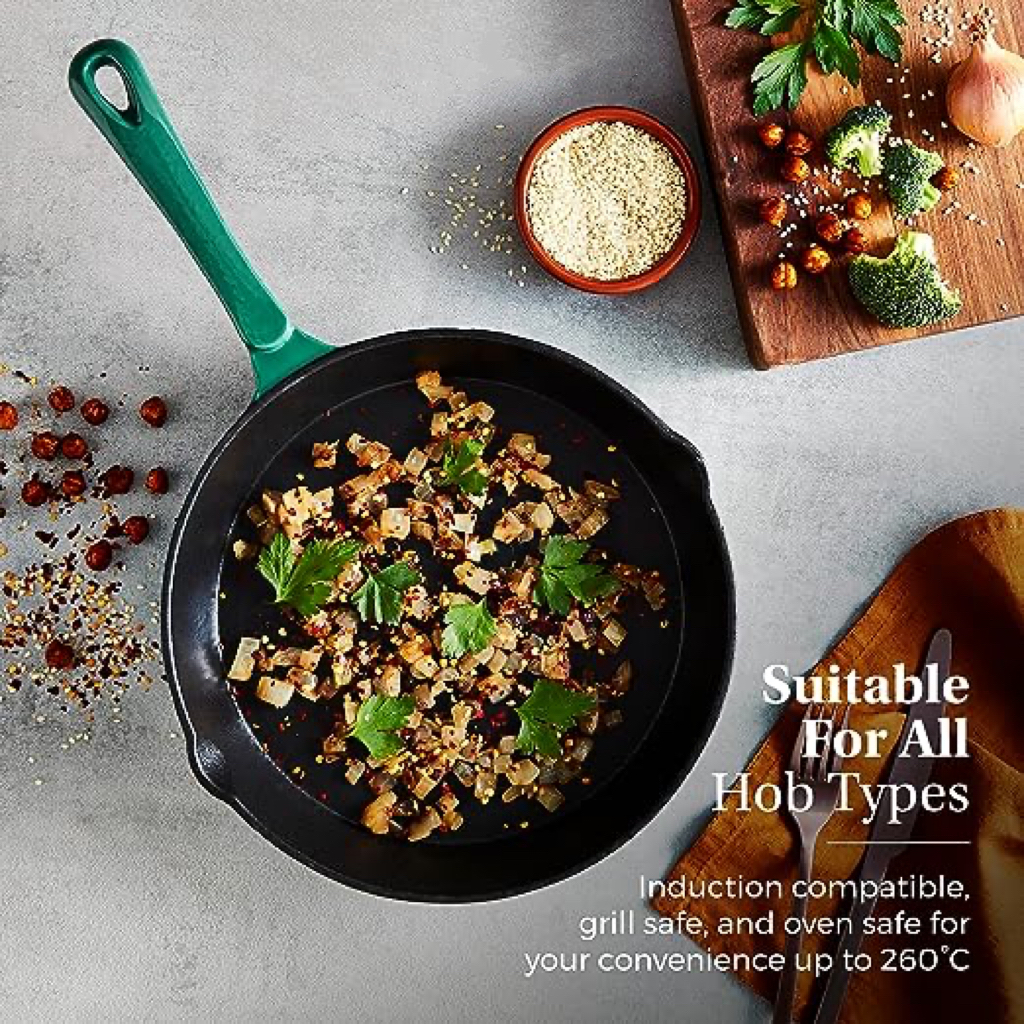

Pans are open to even more interpretation. While most cooks consider a pan to be a sauté pan, the term often refers to all types of cooking vessels. The phrase “pots and pans” is synonymous with general cookware, and “pan” is commonly used when describing other pieces — crepe pan, sheet pan, roasting pan, and the like.

- Enameled cast iron Dutch ovens combine the best of both worlds. They have the same heat retention and distribution properties as cast iron, but the exterior is coated with a layer of enamel, which makes them more resistant to rust and chipping. Enameled cast iron Dutch ovens are also easier to clean than traditional cast iron pots and come in a variety of colors to match any kitchen decor.

- Next, apply a thin, even layer of oil to the pan. You can use any type of oil, but oils with high smoke points, such as vegetable or canola oil, are ideal for this purpose. Use a paper towel or brush to spread the oil evenly across the bottom and sides of the pan.

In conclusion, sizzling steak plates and platters offer a unique and engaging dining experience, allowing for the presentation of sizzling hot meals directly to the table. Whether used in restaurants or home kitchens, these culinary tools enhance the visual appeal and enjoyment of sizzling dishes, creating an interactive and memorable dining experience for diners and guests.

- In conclusion, the blue enamel pot is more than just a kitchen accessory; it is an emblem of serenity amidst the storms of life. Its presence in our homes serves as a daily reminder to slow down, appreciate the little things, and find joy in the simplicity of existence.

- The Timeless Charm of White Cast Iron Pot Sets

- To care for your ceramic and enameled cast iron cookware, it is important to follow some basic guidelines. For ceramic cookware, avoid using metal utensils or abrasive cleaners, as this can damage the non-stick surface. Instead, use wooden or silicone utensils and wash with a soft sponge and mild detergent. For enameled cast iron cookware, avoid using harsh abrasives or metal utensils, as this can chip the enamel coating. Instead, use gentle cleaners and avoid sudden temperature changes to prevent cracking.

- The Art of Grilling with a Grill Pan An Homage to Iron Cookware

- The classic Dutch oven is made from cast iron, which is renowned for its excellent heat retention and distribution. These ovens can be used on stove-tops, in ovens, or even over open fires, making them perfect for both indoor and outdoor cooking. They require seasoning to prevent rusting and improve non-stick properties.

Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration

Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration cast iron enamel pan set.

cast iron enamel pan set. Although they may not be as durable as cast iron, they are ideal for those seeking a healthier cooking option Although they may not be as durable as cast iron, they are ideal for those seeking a healthier cooking option

Although they may not be as durable as cast iron, they are ideal for those seeking a healthier cooking option Although they may not be as durable as cast iron, they are ideal for those seeking a healthier cooking option types of dutch oven.

types of dutch oven.On the other hand, small enamel pots with lids are great for cooking smaller portions or reheating leftovers. Small Enamel Pots With Lids were also great for making sauces, poaching eggs, or cooking grains. The enameled cast iron lid helps retain heat and flavor, making it a practical option for everyday cooking tasks.

These skillets are ideal for high-heat cooking and are compatible with various stovetops, including induction These skillets are ideal for high-heat cooking and are compatible with various stovetops, including induction

These skillets are ideal for high-heat cooking and are compatible with various stovetops, including induction These skillets are ideal for high-heat cooking and are compatible with various stovetops, including induction skillet for sale.

skillet for sale.Choosing a pan definitely doesn’t need to be stressful—and it shouldn’t be. But choosing a great pan definitely takes a bit of research and forethought. First off: what recipes do you actually plan to use it for? If you’re a single cook whose typical weeknight meals consist of single-serving dishes or reheated takeout, a non stick pan is a great affordable, low-fuss option. If seared duck confit, skillet cornbread, and Spanish tortillas sound more like your speed, it may be worth investing in a stainless steel, enameled cast iron, or carbon steel pan in any size.