excavator dredge pump factory

Latest articles

1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

excavator dredge pump factory...

excavator dredge pump factory 【excavator dredge pump factory】

Read MoreStep 2

excavator dredge pump factory...

excavator dredge pump factory 【excavator dredge pump factory】

Read MoreA variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

excavator dredge pump factory...

excavator dredge pump factory 【excavator dredge pump factory】

Read MoreSlurry pump considerations

excavator dredge pump factory...

excavator dredge pump factory 【excavator dredge pump factory】

Read More2. All have vertical pumps and horizontal pumps and can convey slurry.

excavator dredge pump factory...

excavator dredge pump factory 【excavator dredge pump factory】

Read MoreKeep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

excavator dredge pump factory...

excavator dredge pump factory 【excavator dredge pump factory】

Read MoreLonger maintenance intervals

excavator dredge pump factory...

excavator dredge pump factory 【excavator dredge pump factory】

Read MoreWe know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

excavator dredge pump factory...

excavator dredge pump factory 【excavator dredge pump factory】

Read Moretarget=_blank>Slurry Pump

excavator dredge pump factory...

excavator dredge pump factory 【excavator dredge pump factory】

Read MoreAdvantages of rubber

excavator dredge pump factory...

excavator dredge pump factory 【excavator dredge pump factory】

Read More

Popular articles

Latest articles

-

Desire for higher efficiency than centrifugal pumps

-

Step 1

-

Auxiliary equipment

-

>Slurry Pump VS Mud Pump

-

3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

-

Vertical Slurry Pumps Pump Sewage More Efficiently

Links

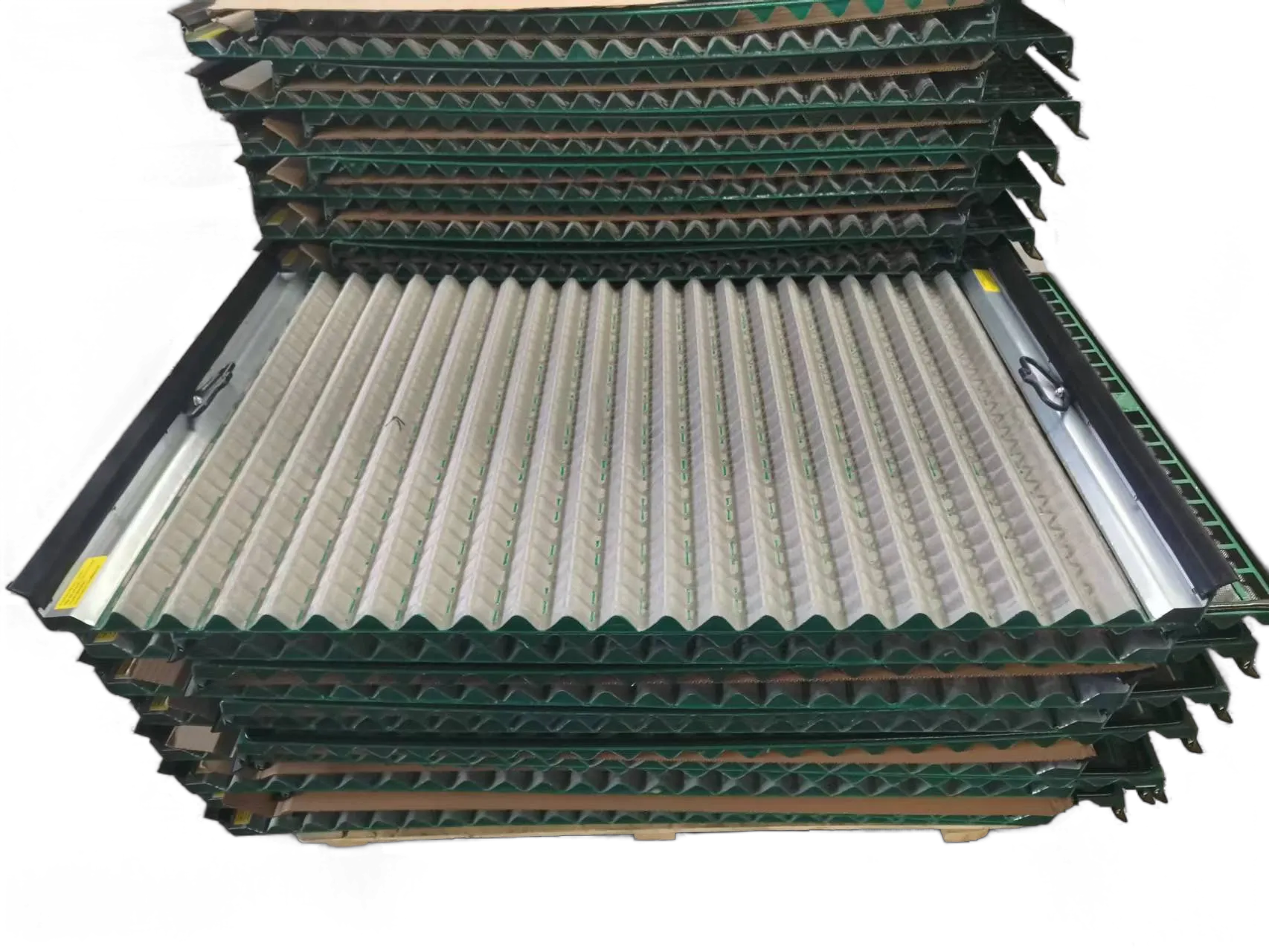

There are five different types of steel grating, each with its own unique applications and benefits. They are

Weight is an essential factor to consider during transportation and installation. Heavier gratings may require specialized equipment for moving and positioning, while lighter options could be handled by fewer personnel. Additionally, the weight can impact the overall load-bearing capacity of the structure where the grating is installed. In applications where heavy machinery or foot traffic is expected, it becomes crucial to choose a weight configuration that ensures longevity and stability.