china slurry pump seals manufacturer

Latest articles

Compared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

china slurry pump seals manufacturer...

china slurry pump seals manufacturer 【china slurry pump seals manufacturer】

Read MoreSlurry Pump

china slurry pump seals manufacturer...

china slurry pump seals manufacturer 【china slurry pump seals manufacturer】

Read MoreA quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

china slurry pump seals manufacturer...

china slurry pump seals manufacturer 【china slurry pump seals manufacturer】

Read MoreSafety

china slurry pump seals manufacturer...

china slurry pump seals manufacturer 【china slurry pump seals manufacturer】

Read MoreIf you've ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. There's no doubt that the slurry on the pump is hard. But the more you know about what's being pumped, the better your pump selection will be, resulting in longer mean time between failures. Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share the following content with you.

china slurry pump seals manufacturer...

china slurry pump seals manufacturer 【china slurry pump seals manufacturer】

Read MoreSlurry Pump

china slurry pump seals manufacturer...

china slurry pump seals manufacturer 【china slurry pump seals manufacturer】

Read MoreIf youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

china slurry pump seals manufacturer...

china slurry pump seals manufacturer 【china slurry pump seals manufacturer】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

china slurry pump seals manufacturer...

china slurry pump seals manufacturer 【china slurry pump seals manufacturer】

Read Moreof a thick consistency, and.

china slurry pump seals manufacturer...

china slurry pump seals manufacturer 【china slurry pump seals manufacturer】

Read MoreAier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

china slurry pump seals manufacturer...

china slurry pump seals manufacturer 【china slurry pump seals manufacturer】

Read More

Popular articles

- Materials of Construction

- reduce the discharge pressure of the pump to the lowest possible point, and.

- A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

- Depending on the abrasive nature of the slurry, it is important to select the ideal seal. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. Vortex pumps use patented seal technology that utilizes a double mechanical seal setup and a separate seal flushing system. This allows the sealing surface to be kept cool at all times without causing the slurry to overheat the seal and crack the surface.

- Larger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

- Slurry pumps can be used for.

Latest articles

-

Consider the following.

-

As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumps help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

-

Slurry pipe diameter.

-

Critical to the engineering of the pump are heavy duty bearing frames and shafts, extra thick wall sections and easily replaceable wear parts. Total life cycle cost considerations are critical when specifying pumps for severe operating conditions, such as FGD service. High chrome pumps are ideal due to the corrosive pH of the slurry.

-

As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

-

Choosing the right slurry pump

Links

- China's contribution to the production of this wire is significant, as the country has become a hub for manufacturing and exporting high-quality galvanized wire. With advanced technology and rigorous quality control measures in place, Chinese manufacturers have managed to optimize the production process, resulting in a product that is both cost-effective and reliable.

In conclusion, 8mm fibreglass rods represent a remarkable fusion of strength, flexibility, and durability, making them invaluable in a multitude of applications. From construction and marine uses to sports and arts, these rods embody the advantages of fibreglass materials. As industries continue to innovate and seek lightweight, resilient components, the 8mm fibreglass rod will undoubtedly remain a popular choice for years to come.

- In conclusion, the 1000% increase in the price of a 20-litre stainless steel water tank can be attributed to a confluence of factors, including rising material costs, increased demand, and supply chain disruptions. While this price hike may be frustrating for consumers, it underscores the importance of investing in durable and reliable storage solutions for clean drinking water. As the world grapples with these challenges, it remains to be seen how long this price surge will persist and what measures will be taken to mitigate its impact on consumers.

- Secondly, the size of the mesh opening plays a role. Smaller openings require more wire and thus, can increase the cost. The standard mesh sizes, such as 1 inch x 1 inch, 2 inches x 4 inches, or 3 inches x 5 inches, have varying prices depending on the specific use case.

When it comes to managing wastewater in residential or commercial properties, septic tanks play a crucial role in ensuring proper sanitation and environmental safety. Among the various types of septic systems available, the 750-gallon fiberglass septic tank stands out due to its size, material, and efficiency. This article explores the advantages, installation, maintenance, and overall significance of a 750-gallon fiberglass septic tank.

When employing flat head roofing nails, it is essential to follow best practices for installation. Ensure that the nails are driven in straight and flush with the surface of the shingles to avoid any potential leaks. A common recommendation is to place nails in a uniform pattern, typically at least four per shingle, depending on the local building codes and the specific roofing material being used.

- In conclusion, China Lost Head Nails is a metaphorical expression encapsulating a significant chapter in Chinese history. It tells a story of cultural transition, technological advancement, and the resilience of a nation navigating through times of change. This phrase serves as a reminder of the importance of preserving our heritage while embracing innovation, a lesson relevant not just to China but to all societies undergoing similar transformations.

- The manufacturing process of steel wire for nail making begins with drawing the wire to the desired diameter. The wire is then subjected to a process called annealing, which involves heating and cooling the wire in a controlled environment. This process softens the wire, making it more malleable and workable, which is crucial for shaping the wire into nail forms.

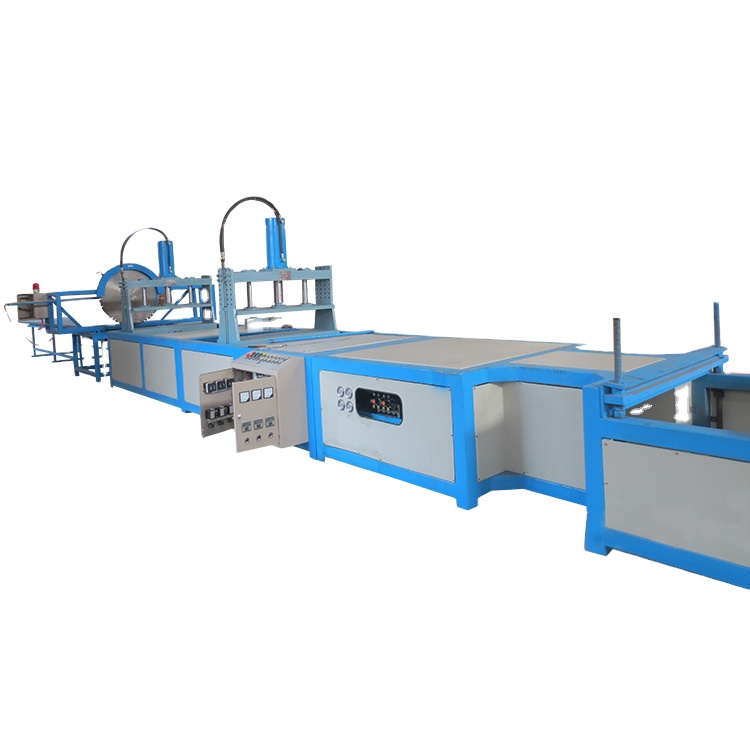

FRP Flat sheet can be manufactured by pultrusion technique,SMC,continous forming and hand lay-up method.

Different technique has different advantage &disvantage. Pls see below form.

The robust construction and sharp edges discourage climbing, thereby enhancing perimeter security without compromising visibility for surveillance purposes The robust construction and sharp edges discourage climbing, thereby enhancing perimeter security without compromising visibility for surveillance purposes

The robust construction and sharp edges discourage climbing, thereby enhancing perimeter security without compromising visibility for surveillance purposes The robust construction and sharp edges discourage climbing, thereby enhancing perimeter security without compromising visibility for surveillance purposes

It can be installed vertically or near-vertically for maximum protection and is suitable for different terrains, from flat land to uneven slopes It can be installed vertically or near-vertically for maximum protection and is suitable for different terrains, from flat land to uneven slopes

It can be installed vertically or near-vertically for maximum protection and is suitable for different terrains, from flat land to uneven slopes It can be installed vertically or near-vertically for maximum protection and is suitable for different terrains, from flat land to uneven slopes