china wetted parts for slurry pump

Latest articles

There is a better way to pump sewage, overflows and other collected dirty water around the plant.

china wetted parts for slurry pump...

china wetted parts for slurry pump 【china wetted parts for slurry pump】

Read MoreWhat is slurry?

china wetted parts for slurry pump...

china wetted parts for slurry pump 【china wetted parts for slurry pump】

Read MoreConveying medium

china wetted parts for slurry pump...

china wetted parts for slurry pump 【china wetted parts for slurry pump】

Read MoreWhen the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

china wetted parts for slurry pump...

china wetted parts for slurry pump 【china wetted parts for slurry pump】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

china wetted parts for slurry pump...

china wetted parts for slurry pump 【china wetted parts for slurry pump】

Read MoreStep 2

china wetted parts for slurry pump...

china wetted parts for slurry pump 【china wetted parts for slurry pump】

Read MoreIt is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

china wetted parts for slurry pump...

china wetted parts for slurry pump 【china wetted parts for slurry pump】

Read MoreUnder ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

china wetted parts for slurry pump...

china wetted parts for slurry pump 【china wetted parts for slurry pump】

Read MoreWhen pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

china wetted parts for slurry pump...

china wetted parts for slurry pump 【china wetted parts for slurry pump】

Read MoreApplications of Rubber Lined Slurry Pumps

china wetted parts for slurry pump...

china wetted parts for slurry pump 【china wetted parts for slurry pump】

Read More

Popular articles

- In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

- Step 3

- Examples of these dubious enhancements to impeller adjustment abound in the industry. One of these is the adjustable wear ring or suction liner to maintain the recommended clearance between the impeller front shroud and the throat bushing face. Almost all >slurry pumps, including AIER® slurry pumps, have features to ensure that this equipment specification can be maintained over time.

- Slurry Pump Impeller Type

- Slurry Pump

- As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

Latest articles

-

Dredge Pump Features

-

- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

-

Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

-

The selection of a dredge or , slurry pump, can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

-

If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

-

Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

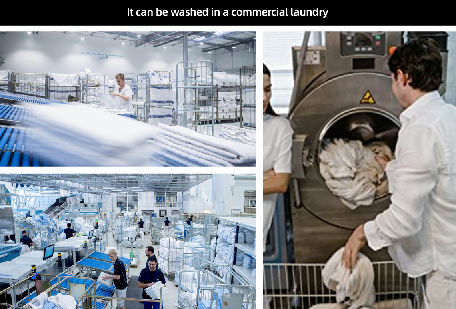

This means that you can enjoy a comfortable night's sleep for years to come This means that you can enjoy a comfortable night's sleep for years to come

This means that you can enjoy a comfortable night's sleep for years to come This means that you can enjoy a comfortable night's sleep for years to come