slurry pump spare parts manufacturer

Latest articles

Desire for higher efficiency than centrifugal pumps

slurry pump spare parts manufacturer...

slurry pump spare parts manufacturer 【slurry pump spare parts manufacturer】

Read MoreAs this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

slurry pump spare parts manufacturer...

slurry pump spare parts manufacturer 【slurry pump spare parts manufacturer】

Read MoreThere is a better way to pump sewage, overflows and other collected dirty water around the plant.

slurry pump spare parts manufacturer...

slurry pump spare parts manufacturer 【slurry pump spare parts manufacturer】

Read MoreAier is pumping experts and offer some useful tips to maintain your >slurry pump.

slurry pump spare parts manufacturer...

slurry pump spare parts manufacturer 【slurry pump spare parts manufacturer】

Read MoreWZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

slurry pump spare parts manufacturer...

slurry pump spare parts manufacturer 【slurry pump spare parts manufacturer】

Read MoreIf you want to know more information about the best heavy duty slurry pump, welcome to >contact us today or request a quote.

slurry pump spare parts manufacturer...

slurry pump spare parts manufacturer 【slurry pump spare parts manufacturer】

Read MoreProcess speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

slurry pump spare parts manufacturer...

slurry pump spare parts manufacturer 【slurry pump spare parts manufacturer】

Read MoreAs new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumps help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

slurry pump spare parts manufacturer...

slurry pump spare parts manufacturer 【slurry pump spare parts manufacturer】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

slurry pump spare parts manufacturer...

slurry pump spare parts manufacturer 【slurry pump spare parts manufacturer】

Read MoreCarbon transfer

slurry pump spare parts manufacturer...

slurry pump spare parts manufacturer 【slurry pump spare parts manufacturer】

Read More

Popular articles

- As described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

- - Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

- How does a dredge pump work?

- Slurry Pump

- The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

- The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

Latest articles

-

It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

-

Dredge Pump Features

-

- Keeping clean catch basins clean from solids

-

As the slurry is collected at the bottom of the tower, more rubber lined pumps are required to transfer the slurry to storage tanks, tailings ponds, waste treatment facilities or filter presses. Depending on the type of FGD process, other pump models are available for slurry discharge, pre-scrubber recovery and catch basin applications.

-

how-does-a-dredge-pump-work

-

If you've ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. There's no doubt that the slurry on the pump is hard. But the more you know about what's being pumped, the better your pump selection will be, resulting in longer mean time between failures. Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share the following content with you.

Links

4. Sustainability

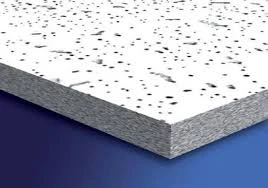

Companies like Knauf Insulation, Rockwool International, and Owens Corning have established themselves as leaders in the mineral fiber board market. They invest heavily in research and development to enhance product performance and sustainability. The competitive landscape encourages constant innovations, leading to a variety of products tailored to specific customer needs and market requirements.

Installation of acoustic mineral boards is another advantage. The boards can be applied in both ceiling and wall applications, often requiring simple mounting techniques that do not compromise structural integrity. This ease of installation can significantly reduce labor costs and time, making it a practical choice for both new constructions and renovations.

In summary, ceiling inspection hatches are indispensable components in building maintenance that support accessibility, safety, performance, cost-effectiveness, and design flexibility. As buildings continue to age and their systems require regular attention, the importance of these hatches cannot be overstated. By facilitating efficient inspections and maintenance activities, ceiling inspection hatches contribute significantly to the sustainability and longevity of building infrastructure, ensuring a safer and more functional environment for all occupants.

Another contributing factor to the popularity of mineral fiber ceiling boards is their ease of installation. The lightweight nature of the material allows for quick and straightforward handling during the construction process. Many manufacturers offer systems that provide options for suspended ceilings, which can be easily installed over existing ceilings or structures. This not only simplifies installation but also allows for access to plumbing and electrical systems above the ceiling.

3. Metal Panels Metal ceiling panels are gaining popularity for their industrial aesthetic. They are available in various finishes, including brushed aluminum and galvanized steel. Metal panels are highly durable, easy to clean, and can be designed to create striking visual effects. They are particularly suited for high-end commercial spaces and modern residential applications.

The drywall grid system is a widely used method in the construction industry for creating ceilings and walls that are both aesthetically pleasing and functionally sound. This technique involves the installation of a grid framework that supports drywall panels, allowing for various design options and easy access to utilities hidden behind wall surfaces. Understanding the components, benefits, and installation process of a drywall grid system can greatly enhance the efficiency and effectiveness of interior construction projects.

In today’s eco-conscious world, the sustainability of building materials is more important than ever. Mineral fiber ceilings are often made from recycled content and are recyclable themselves, reducing their environmental impact. Many manufacturers are committed to sustainable practices, ensuring that their products meet or exceed environmental standards. By choosing mineral fiber ceilings, builders and designers can contribute to greener construction practices while maintaining high performance and aesthetics.

3. Sound Insulation Gypsum tiles offer excellent sound insulation, making them an ideal choice for spaces that require noise reduction, such as recording studios, offices, or residential homes. They help in dampening sound transmission between rooms, enhancing privacy and comfort.

- Adjustments for Utilities When installing the grid system, it is necessary to account for any existing utilities above the ceiling. Proper measurements and adjustments may be needed to navigate around plumbing or electrical wiring.

- 12 x 12

3. Easy Installation and Maintenance

Mineral fiber ceilings find utility in various sectors, including education, healthcare, commercial office spaces, and manufacturing. In educational settings, these ceilings help create quiet environments conducive to learning. In healthcare facilities, they contribute to patient comfort by reducing noise, which is critical for recovery. Commercial offices benefit from the aesthetic appeal of mineral fiber tiles, which come in various designs, colors, and finishes, allowing for creative interior design options.

mineral fibre ceiling

Conclusion

In conclusion, mineral wool board is a highly effective insulation material that boasts impressive R-values, making it an excellent choice for both residential and commercial applications. Its unique properties, including fire resistance, sound absorption, and moisture resistance, further enhance its appeal. When considering insulation options, the R-value should be a critical factor in your decision-making process, and mineral wool board certainly deserves attention for its outstanding performance.

Access panels are essential components in both residential and commercial construction, especially when it comes to maintaining essential systems like plumbing, electrical, and HVAC. One of the increasingly popular materials for these panels is plastic. This article provides an overview of plastic ceiling access panels for drywall, discussing their benefits, installation, and applications.

Understanding Grid Ceiling Systems

Applications in Design

Installing a T-Bar drop ceiling requires precise measurement and planning. The process begins with measuring the room dimensions and marking the desired height of the ceiling. Once the layout is established, the T-Bar grid is secured to the walls and suspended from the main ceiling with hangers. It is essential to ensure that the grid is level and properly spaced to support the weight of the ceiling tiles.

Gypsum ceiling access panels are a smart solution for both new construction and renovation projects, combining function and design. Their ability to provide discreet access to vital building systems while maintaining an unobtrusive appearance makes them a valuable addition to any architectural plan. By considering the installation and maintenance of these panels, builders and property owners can improve the efficiency and longevity of their buildings, ensuring that all systems remain accessible without compromising the aesthetic of the space. As the architectural landscape continues to evolve, gypsum ceiling access panels will undoubtedly remain a key element in modern building practices.

4. Type of Ceiling The ceiling structure can influence the size of the access panel needed. For instance, in suspended ceiling designs, panels need to match the grid systems, often necessitating specific dimensions to fit seamlessly into the existing architecture.

Next, mark the desired height of the ceiling and install a perimeter track around the room using screws or anchors, according to the manufacturer’s specifications. The plastic grid sections are then hung from the ceiling joists using clips or wire hangers, ensuring that they are level and securely attached. Once the framework is established, the ceiling tiles can be easily inserted into the grid system.

When comparing costs, PVC ceilings are often more cost-effective than gypsum ceilings. The materials themselves tend to be less expensive, and the ease of installation can lead to savings on labor. PVC is also less prone to damage over time, which can reduce maintenance costs.

Conclusion

4. Attaching to the Grid Once the wires are in place, they should be connected to the main beams of the grid system, ensuring that they are tightened adequately to minimize movement.

Conclusion

Plasterboard ceiling hatches, also known as access hatches or inspection hatches, play a crucial role in modern construction and renovation projects. These hatches provide easy access to areas above the ceiling, such as plumbing, electrical systems, and HVAC installations, allowing for inspections, repairs, and maintenance without the need for extensive demolition work. By understanding their functions, benefits, and installation process, homeowners and contractors can make informed decisions when incorporating these hatches into their designs.

Beyond practicality, ceiling trap doors evoke a sense of adventure and curiosity. They have become an iconic feature in literature and film, often representing a gateway to a hidden world. When a trap door is opened, it can unveil secrets, treasures, or unexpected spaces. For this reason, many designers incorporate trap doors into commercial settings like cafes, theaters, and art galleries to create interactive experiences for customers and guests. This element of surprise plays into the human fascination with the unknown, making ceiling trap doors a trending design choice for those looking to add an element of intrigue to their spaces.

Sustainability and Innovation

One of the primary advantages of PVC laminated gypsum tiles is their durability. The PVC layer is resistant to moisture, making these tiles suitable for areas that experience high humidity, such as bathrooms and kitchens. Unlike traditional tiles that might absorb water and become damaged over time, PVC laminated tiles will maintain their integrity and appearance, even in challenging conditions. This water resistance is coupled with the inherent durability of gypsum, which can withstand everyday wear and tear.

- Healthcare Facilities In hospitals and clinics, ceiling access hatches can be crucial for accessing critical systems that support patient care, making maintenance quicker and more efficient without disrupting operations.

Ease of Maintenance

Fire-rated ceiling access doors are designed to provide access to spaces above ceilings—like mechanical systems, electrical wiring, and plumbing—while also preventing the spread of fire. These doors are constructed using materials that can withstand high temperatures for a specified duration, thereby limiting the fire's ability to pass through the ceiling fixtures.

Gypsum ceiling access panels are an essential component of modern construction, particularly for spaces requiring maintenance and easy access to ceiling-mounted utilities such as plumbing, electrical wiring, and HVAC systems. These panels provide a seamless and aesthetically pleasing solution for both residential and commercial buildings, blending functionality with design. In this article, we will explore what gypsum ceiling access panels are, their advantages, installation procedures, and common applications.

Considerations for Choosing Grid Ceiling Materials

A watertight access panel is a specialized enclosure that allows for easy entry into areas such as walls, ceilings, or floors without compromising the integrity of the surrounding structure. These panels are typically constructed from durable materials like stainless steel or heavy-duty plastic and are equipped with seals that create a tight barrier against water ingress. This feature is particularly important in environments where moisture exposure can lead to significant structural damage or safety hazards.

1. Location The hatch should be installed in an easily accessible location. Careful planning is necessary to avoid placing hatches directly over fixtures or furniture.

Utilizing the attic for storage is not just about creating space; it’s also about organization. With proper bins and shelving, items stored in the attic can be neatly categorized and easily accessible. This can be especially beneficial in homes where storage options are limited, such as smaller houses or apartments. The attic ceiling hatch becomes not just a physical access point, but a portal to a more organized and decluttered home.

Aesthetic Significance

3. Enhanced Aesthetics Modern hatch designs ensure that aesthetic considerations are met. Many manufacturers create hatches that can be painted or finished to match the surrounding ceiling, making them less obtrusive and easier to integrate into the overall design.

Acoustic performance is also a significant consideration in any ceiling design. Calcium silicate grid ceilings offer excellent sound absorption properties, helping to reduce noise levels in busy environments, such as offices, restaurants, and schools. By minimizing sound reverberation, these ceilings contribute to a more pleasant and productive atmosphere.

Installation Considerations

1. Acoustic Tiles One of the most common materials, acoustic tiles are designed to absorb sound, making them ideal for offices, schools, and other environments where noise reduction is essential. Typically made from mineral fiber or fiberglass, these tiles are lightweight, easy to install, and can be found in various designs and finishes, enhancing the aesthetic of the space.

When it comes to the installation of suspended ceiling access panels, several factors must be taken into account to ensure a successful integration with the ceiling system. First, it is crucial to choose the correct size and style of the panel to match the ceiling’s design and the intended use. The weight of the panel and the materials used for the ceiling must also be compatible to maintain structural integrity.

Beyond aesthetics, flush ceiling hatches serve critical operational purposes. They provide crucial access for maintenance and repairs of essential systems, including electrical wiring, HVAC ducts, and plumbing lines. Regular inspections and potential repairs are vital for ensuring that these systems function effectively and safely. A flush hatch allows maintenance personnel to perform their work without the need for extensive remodeling or disruption of the living space.

flush ceiling hatch