vertical sump pump parts

Latest articles

Non-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

vertical sump pump parts...

vertical sump pump parts 【vertical sump pump parts】

Read MoreWhat is the optimum seal arrangement for the application?

vertical sump pump parts...

vertical sump pump parts 【vertical sump pump parts】

Read MoreThe concept of the , slurry pump, and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

vertical sump pump parts...

vertical sump pump parts 【vertical sump pump parts】

Read Morereduce the discharge pressure of the pump to the lowest possible point, and.

vertical sump pump parts...

vertical sump pump parts 【vertical sump pump parts】

Read MoreUnder ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

vertical sump pump parts...

vertical sump pump parts 【vertical sump pump parts】

Read MoreSlurry pump construction materials

vertical sump pump parts...

vertical sump pump parts 【vertical sump pump parts】

Read MoreKeep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

vertical sump pump parts...

vertical sump pump parts 【vertical sump pump parts】

Read More1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

vertical sump pump parts...

vertical sump pump parts 【vertical sump pump parts】

Read MoreAbrasive.

vertical sump pump parts...

vertical sump pump parts 【vertical sump pump parts】

Read MoreThere is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

vertical sump pump parts...

vertical sump pump parts 【vertical sump pump parts】

Read More

Popular articles

- target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

- The rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

- Submersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

- - Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

- Dredge Pump

- Light-duty Slurry Pump

Latest articles

-

method and level of design reach international advanced level. The company has the first-class pump performance

-

Using rubber as a wear lining material means

-

When dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

-

Vertical Slurry Pump

-

Underwater installation

-

The terms slurry pump and dredge pump can be used interchangeably.

Links

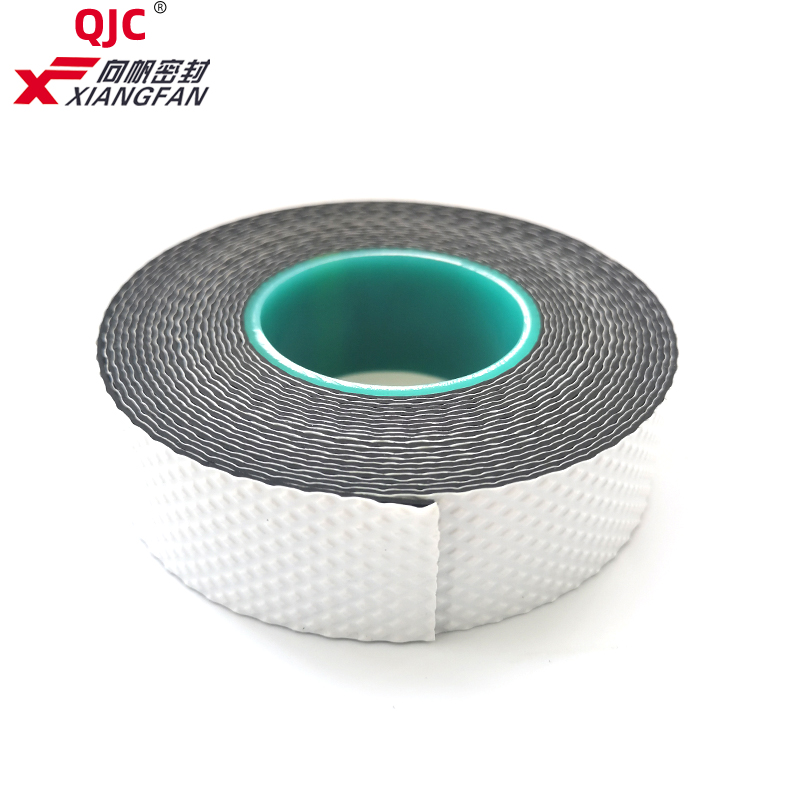

- Flexibility and Conformability: Rubber adhesives remain flexible and conformable even after application. This allows the tape to adhere well to irregular or uneven surfaces, ensuring a tight and secure bond. The flexibility of the rubber adhesive enables it to accommodate movement or slight variations in the bonded surfaces.

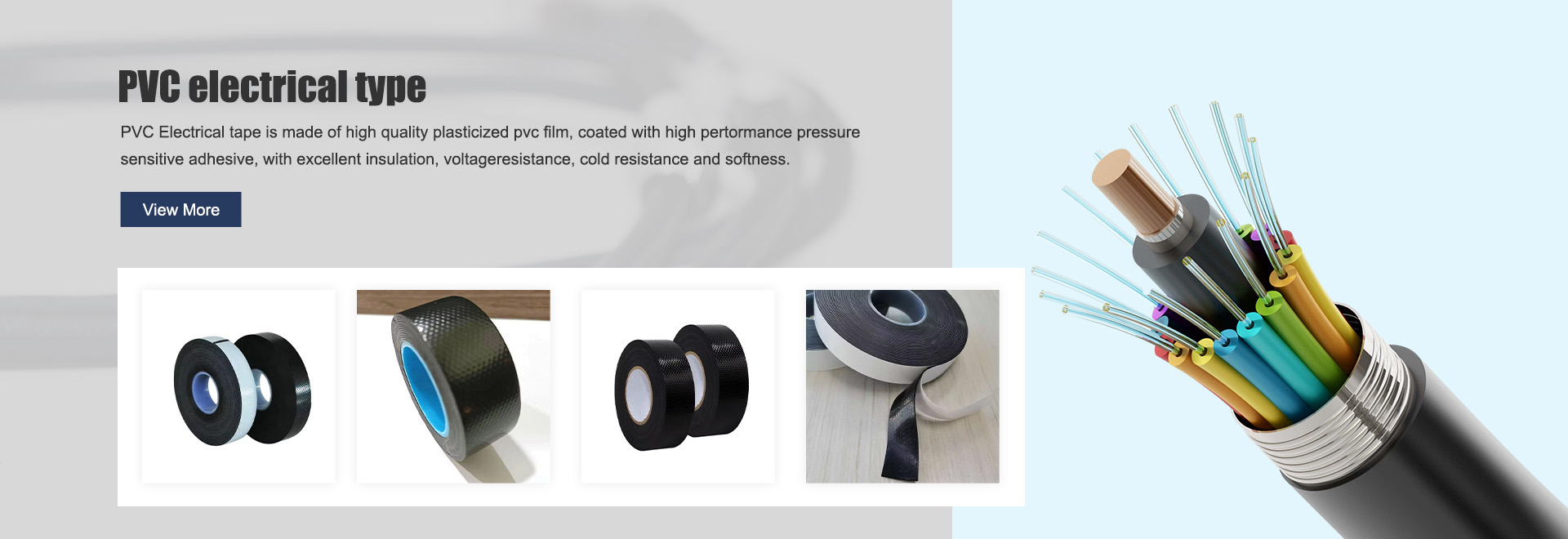

Care must be taken to ensure that the tape is wrapped evenly and tightly, without any gaps or overlaps, to maximize its protective properties Care must be taken to ensure that the tape is wrapped evenly and tightly, without any gaps or overlaps, to maximize its protective properties

Care must be taken to ensure that the tape is wrapped evenly and tightly, without any gaps or overlaps, to maximize its protective properties Care must be taken to ensure that the tape is wrapped evenly and tightly, without any gaps or overlaps, to maximize its protective properties It can be easily cleaned with soap and water, and does not require any special cleaning agents It can be easily cleaned with soap and water, and does not require any special cleaning agents

It can be easily cleaned with soap and water, and does not require any special cleaning agents It can be easily cleaned with soap and water, and does not require any special cleaning agents