china wastewater grinder centrifugal pump

Latest articles

As described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

china wastewater grinder centrifugal pump...

china wastewater grinder centrifugal pump 【china wastewater grinder centrifugal pump】

Read MoreThe main objective of all flush water programmes is to prevent contamination of the seals by pumped water.The flush water programme for boxes is therefore very similar to the flush water programme for mechanically sealed boxes. However there are still some obvious mechanical differences. The most notable difference is the addition of a seal (packing) between the inlet and outlet limits. This minimises the amount of flushing fluid consumed.

china wastewater grinder centrifugal pump...

china wastewater grinder centrifugal pump 【china wastewater grinder centrifugal pump】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

china wastewater grinder centrifugal pump...

china wastewater grinder centrifugal pump 【china wastewater grinder centrifugal pump】

Read More- Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

china wastewater grinder centrifugal pump...

china wastewater grinder centrifugal pump 【china wastewater grinder centrifugal pump】

Read MoreWill solids size pass through the pump?

china wastewater grinder centrifugal pump...

china wastewater grinder centrifugal pump 【china wastewater grinder centrifugal pump】

Read More- Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

china wastewater grinder centrifugal pump...

china wastewater grinder centrifugal pump 【china wastewater grinder centrifugal pump】

Read More3. Both pumps and motors are designed separately.

china wastewater grinder centrifugal pump...

china wastewater grinder centrifugal pump 【china wastewater grinder centrifugal pump】

Read MoreAs this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

china wastewater grinder centrifugal pump...

china wastewater grinder centrifugal pump 【china wastewater grinder centrifugal pump】

Read MoreApplications of Rubber Lined Slurry Pumps

china wastewater grinder centrifugal pump...

china wastewater grinder centrifugal pump 【china wastewater grinder centrifugal pump】

Read MoreWL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

china wastewater grinder centrifugal pump...

china wastewater grinder centrifugal pump 【china wastewater grinder centrifugal pump】

Read More

Popular articles

- BCT Ceramic Slurry Pumps

- Applications of Rubber Lined Slurry Pumps

- Slurry Pump

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

- Slurry Pump

Latest articles

-

How to choose a slurry pump?

-

Slurry pump vs mud pump

-

Some quench seals are planned to replace the tight fitting outlet restriction with a secondary seal and a top outlet that can be piped to capture the used quench fluid and drain it from the rotating assembly. However the principle is the same, we try to cool the seal rather than flush it in any way.

-

Some models can generate discharge pressures up to 260 ft. (80 m).

-

Follow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

-

What is Heavy Duty Slurry Pump?

Links

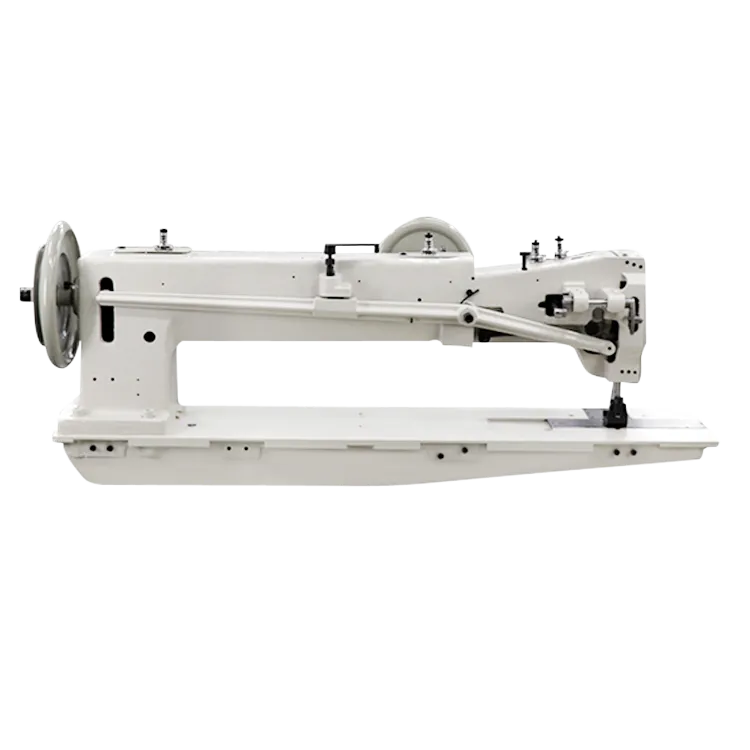

When selecting a double needle leather sewing machine, several features should be considered to ensure it meets your crafting needs

- In conclusion, the price of an automatic industrial sewing machine is an important factor to consider when looking to purchase a new machine for your business. By evaluating your needs, budget, and the features and capabilities of different machines, you can make an informed decision that will help you improve productivity and meet the demands of your customers. Investing in a high-quality automatic industrial sewing machine is essential for any business in the textile industry, and choosing a machine that offers the best value for your money will pay off in the long run.

Before diving into the sewing process, it's essential to understand the different types of leather. Full-grain leather is the most durable and retains the natural texture of the hide. Top-grain leather is slightly more processed and has a smoother finish. Suede is made from the underside of the hide and has a soft texture, while bonded leather combines leather scraps with synthetic materials. Each type has its own sewing requirements, so it's crucial to choose the right leather for your project.

7. Automatic Features

The PP bag silai machine is a transformative solution in the production of polypropylene bags, enhancing efficiency, quality, and sustainability. As industries increasingly shift towards eco-friendly practices, the demand for these machines is expected to rise. Investing in advanced sewing technology will not only improve manufacturing processes but also position businesses to meet the evolving needs of consumers and the environment. In summary, the PP bag silai machine stands at the forefront of industrial innovation, driving the future of packaging solutions.

Moreover, serger machine sales are often accompanied by online resources and community support. Many retailers provide instructional videos and workshops to help new users get acquainted with their machines. Online platforms also serve as a hub for buying and selling second-hand machines, which further democratizes access to quality equipment at lower prices. The challenge of acquiring a serger is thus diminished, allowing enthusiasts to focus on what they love creating.

Safety features also enhance the user experience. Many heavy-duty sewing machines come equipped with features like a built-in needle guard, which prevents accidental needle punctures, and a foot pedal with an anti-slip surface for better control. These thoughtful designs add an extra layer of security, allowing users to focus on their projects with confidence.

- Sturdy Construction: These machines are typically made with a durable metal frame and parts, providing stability and reducing vibrations during operation. This construction ensures longevity and reliability, even when used for extended periods.