china dredge pump for sand manufacturers

Latest articles

What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

china dredge pump for sand manufacturers...

china dredge pump for sand manufacturers 【china dredge pump for sand manufacturers】

Read MoreWhat style of pump is suitable?

china dredge pump for sand manufacturers...

china dredge pump for sand manufacturers 【china dredge pump for sand manufacturers】

Read MoreSelecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

china dredge pump for sand manufacturers...

china dredge pump for sand manufacturers 【china dredge pump for sand manufacturers】

Read MoreAs new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

china dredge pump for sand manufacturers...

china dredge pump for sand manufacturers 【china dredge pump for sand manufacturers】

Read MoreHow much solids damage can the customer tolerate?

china dredge pump for sand manufacturers...

china dredge pump for sand manufacturers 【china dredge pump for sand manufacturers】

Read MoreA slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

china dredge pump for sand manufacturers...

china dredge pump for sand manufacturers 【china dredge pump for sand manufacturers】

Read MoreMud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

china dredge pump for sand manufacturers...

china dredge pump for sand manufacturers 【china dredge pump for sand manufacturers】

Read MoreFewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

china dredge pump for sand manufacturers...

china dredge pump for sand manufacturers 【china dredge pump for sand manufacturers】

Read MoreA slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

china dredge pump for sand manufacturers...

china dredge pump for sand manufacturers 【china dredge pump for sand manufacturers】

Read MoreIn addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

china dredge pump for sand manufacturers...

china dredge pump for sand manufacturers 【china dredge pump for sand manufacturers】

Read More

Popular articles

- In a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

- Dredge pumps are designed to transfer large quantities of fluids and solids.

- Choosing The Right Slurry Pump For Your Application

- Choosing the Right Pump for Flue Gas Desulphurisation

- Larger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

- How does a dredge pump work?

Latest articles

-

Compared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

-

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

-

A , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

-

The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

-

Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

-

- Pumping the final product in a process

Links

- When using heavy duty thread for sewing leather, it is important to choose the right type and weight of thread for the job. There are several different types of heavy duty thread available, including nylon, polyester, or even waxed thread. The weight of the thread can also vary, with heavier weights being better suited for thicker leather and lighter weights being better for thinner leather.

2. Aesthetic Appeal Overlocking leaves carpets looking professional and polished. The machine creates smooth, clean edges, enhancing the overall appearance of the finished product, which is especially important for retail settings.

Excellent Customer Support

Sewing is a skill that has been treasured for centuries, enabling individuals to create, repair, and express their creativity through fabric and thread. At the core of every successful sewing project lies a crucial element the sewing machine needle. Among the various types of needles available, strong sewing machine needles stand out as essential for achieving the best results, especially when working with thick fabrics or heavy-duty sewing projects.

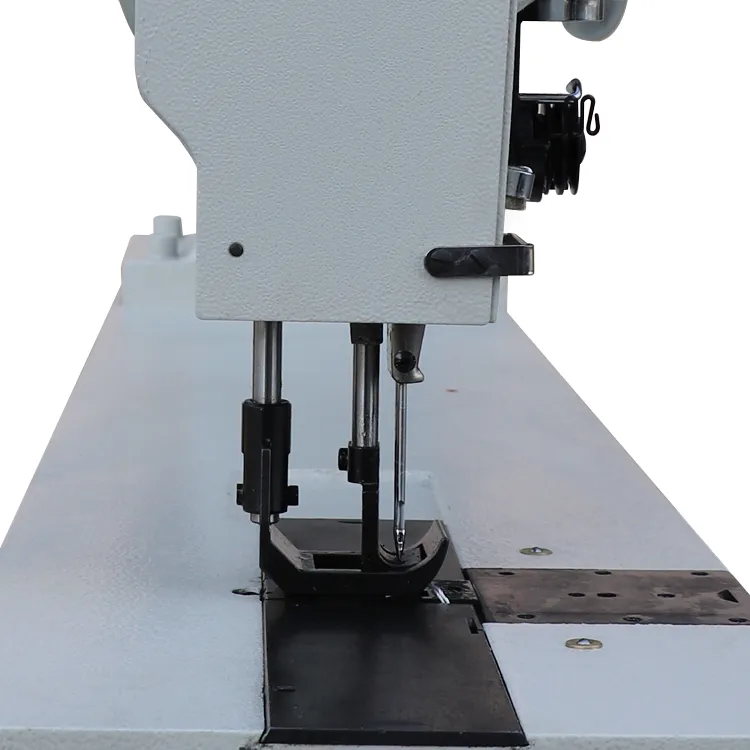

- Maintenance of the lockstitch machine is important to ensure its longevity and optimal performance. Regular cleaning, lubrication, and adjustments are necessary to prevent thread jamming, needle breakage, and other issues that can affect the quality of the stitch.

Durability is a hallmark of heavy-duty sewing machines. Designed to withstand rigorous use, these machines boast metal frames that provide stability and longevity. This rugged construction is particularly appealing for users who predict a high volume of sewing, whether for personal projects or small business operations. Unlike lightweight models that may falter under heavy workloads, a heavy-duty machine is built to last, ensuring that it remains a reliable companion for years to come.

Industrial Sewing Machines: Due to their specialized nature, there might be a steeper learning curve associated with industrial machines. They are often designed with professionals in mind, prioritizing efficiency and precision over user-friendly features.

- When using a seaming machine, it is important to follow the manufacturer's instructions carefully to ensure optimal performance and longevity of the machine. Regular maintenance and cleaning are also essential to prevent issues such as thread jams and skipped stitches.

One of the standout features of the coverstitch machine is its ability to create a variety of stitch widths and types. This adaptability means that sewists can move beyond standard hems, using the machine to embellish edges or create unique design elements, such as decorative stitching along seams. As a result, the coverstitch machine is an indispensable tool for anyone looking to produce high-quality, professional-grade apparel.

Selecting the Right Strong Needle

Industrial Sewing Machines: These are large, often fixed to tables, and are not meant to be moved frequently. They require a dedicated space, and their setup indicates a permanent or semi-permanent sewing station.

One of the key advantages of using a double needle coverstitch is its ability to provide a durable seam that won't easily unravel. Unlike standard sewing techniques that can compromise the integrity of the seam when stretched, the coverstitch uses a combination of straight stitching and chain stitching to absorb tension without breaking. This is particularly important in areas of a garment that experience a lot of wear and movement, such as armholes, waistbands, and hems.

Choosing the Right Walking Foot Sewing Machine

3. Versatility This technique can be applied to a wide range of fabrics, particularly knit and stretch materials. Whether you're sewing casual t-shirts, activewear, or even some types of woven fabrics, the coverstitch will deliver impressive results.

4. Bernina 770 QE For those who are ready to invest in a high-end model, the Bernina 770 QE is a luxurious option that offers a wide array of features, including a dual feed system and a large sewing area. It’s an excellent choice for serious leather crafters looking for professional quality.

In summary, sewing machines designed for fabric and leather vary significantly in terms of functionality and specifications. To choose the right machine, consider the materials you'll be working with, the types of projects you plan to undertake, and the features necessary to handle various sewing tasks. Whether you're crafting intricate garments or durable leather goods, a well-chosen sewing machine will enhance your creativity and ensure your projects are completed with professional quality. Happy sewing!

Industrial Long Arm Sewing Machines for Sale A Comprehensive Guide

When you use a heavy duty industrial walking foot sewing machine- it comes with a built-in walking foot mechanism. This is very different that most walking foot attachments that only snap-on regular household sewing machines.

In the world of manufacturing, particularly in the footwear industry, the advent of automatic shoe sewing machines has revolutionized the production process. These sophisticated machines have not only enhanced efficiency but also improved the quality of shoe manufacturing, paving the way for innovations that cater to both mass production and bespoke shoe creation.

Enhancing Creativity

Understanding PP Woven Bags

1. Versatility One of the primary advantages of heavy-duty sewing machines is their versatility. They can sew through various materials, making them ideal for a wide range of projects. Whether you are working on fashion design, upholstery, or crafting sturdy outdoor gear, a heavy-duty machine can tackle it all with ease.

The versatility of this machine makes it suitable for a wide array of projects. Quilters can create stunning quilt tops with intricate zig zag patterns, while garment makers can sew durable seams that withstand the rigors of everyday wear. Crafters working on home décor items can also benefit from the machine’s ability to handle heavier fabrics with ease. The beauty of the long arm zig zag sewing machine lies in its adaptability—it seamlessly transitions between professional and personal projects, making it a must-have for any sewing enthusiast.

Finally, a regular sewing machine will be easier to operate, compared to a heavy-duty machine. For example, they will tend to be slower, making them easier to control. In addition, threading a heavy-duty machine might be slightly more difficult. Also, most heavy-duty machines don’t have a plastic casing around the engine. This will prevent it from overheating. However, the more frequently you use a heavy-duty sewing machine, the easier it will be for you to adjust to these operational differences.

The long arm sewing machine is specifically designed for handling larger projects and materials that require extensive stitching. Its extended arm allows for an enhanced sewing area, accommodating bulky items like sails, awnings, and large canvas covers, which traditional sewing machines struggle to manage. One of the standout features of this machine is its puller attachment, which acts as a feeding mechanism that ensures smooth movement of the fabric while sewing.