china rubber slurry pump parts manufacturers

Latest articles

Light-duty Slurry Pump

china rubber slurry pump parts manufacturers...

china rubber slurry pump parts manufacturers 【china rubber slurry pump parts manufacturers】

Read MoreSlurry pump power adjustment

china rubber slurry pump parts manufacturers...

china rubber slurry pump parts manufacturers 【china rubber slurry pump parts manufacturers】

Read MoreSlurry Pump VS Mud Pump

china rubber slurry pump parts manufacturers...

china rubber slurry pump parts manufacturers 【china rubber slurry pump parts manufacturers】

Read MoreWhat is a dredging pump?

china rubber slurry pump parts manufacturers...

china rubber slurry pump parts manufacturers 【china rubber slurry pump parts manufacturers】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

china rubber slurry pump parts manufacturers...

china rubber slurry pump parts manufacturers 【china rubber slurry pump parts manufacturers】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our

china rubber slurry pump parts manufacturers...

china rubber slurry pump parts manufacturers 【china rubber slurry pump parts manufacturers】

Read MoreThe slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

china rubber slurry pump parts manufacturers...

china rubber slurry pump parts manufacturers 【china rubber slurry pump parts manufacturers】

Read MoreWith the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

china rubber slurry pump parts manufacturers...

china rubber slurry pump parts manufacturers 【china rubber slurry pump parts manufacturers】

Read MoreMill sump

china rubber slurry pump parts manufacturers...

china rubber slurry pump parts manufacturers 【china rubber slurry pump parts manufacturers】

Read MorePumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

china rubber slurry pump parts manufacturers...

china rubber slurry pump parts manufacturers 【china rubber slurry pump parts manufacturers】

Read More

Popular articles

- Rubber lined pumps offer many advantages

- Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

- Slurry Pump

- The mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

- of a thick consistency, and.

- If you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

Latest articles

-

The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

-

reduce the discharge pressure of the pump to the lowest possible point, and.

-

What are the materials used to construct the pump?

-

Determine the nature of the material to be pumped

-

Desire for higher efficiency than centrifugal pumps

-

Selecting a dredge pump

Links

- Furthermore, gymnasium floor tape is designed to be durable and long-lasting, ensuring that it can withstand the wear and tear of intense athletic activity. This means that sports facilities can rely on their floor tape to provide clear markings and boundaries game after game, season after season.

There are many affordable control boxes you can purchase that will suit your needs, just be wary of the things that you don’t need because the price will be higher.

Another feature that sets insulation cotton tape apart from its peers is its durability. It withstands extreme temperatures and is resistant to moisture, ensuring that it remains effective under various conditions. This resilience makes it suitable for both indoor and outdoor applications. Whether it’s sealing pipes in a plumbing project or providing thermal protection for outdoor electrical installations, insulation cotton tape proves its versatility time and again.

This makes it ideal for long-term use in both residential and commercial settings This makes it ideal for long-term use in both residential and commercial settings

This makes it ideal for long-term use in both residential and commercial settings This makes it ideal for long-term use in both residential and commercial settings fireproof tape.

fireproof tape.In plumbing repairs, amalgamating rubber tape is often used to fix leaks and reinforce pipe joints

. The tape can be applied to the damaged area and wrapped tightly to create a waterproof seal. Its flexibility and strength make it an ideal solution for emergency repairs or as a temporary fix until a permanent solution can be implemented.amalgamating rubber tape

Conclusion

Now that we know everything there is to know about butyl tape, read through these last couple of points to help you purchase and apply this diverse adhesive tape.

For all intents and purposes, modified acrylics have the same characteristics as pure acrylics, but have superior adhesion to the hard-to-bond-plastics mentioned above. Generally, these are more expensive than pure acrylics and are used for plastic bonding (including vinyl and linoleum), lamination and splicing.

Types of Butyl Rubber Sealant Tape

1. Inspect the Area Check for any gaps around doors and windows. A simple test is to close a door or window and see if light passes through; if it does, weather stripping is needed.

It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments

It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments insulation tape yellow. It can also be easily trimmed to size using scissors or a utility knife, allowing workers to customize the tape to fit their specific needs.

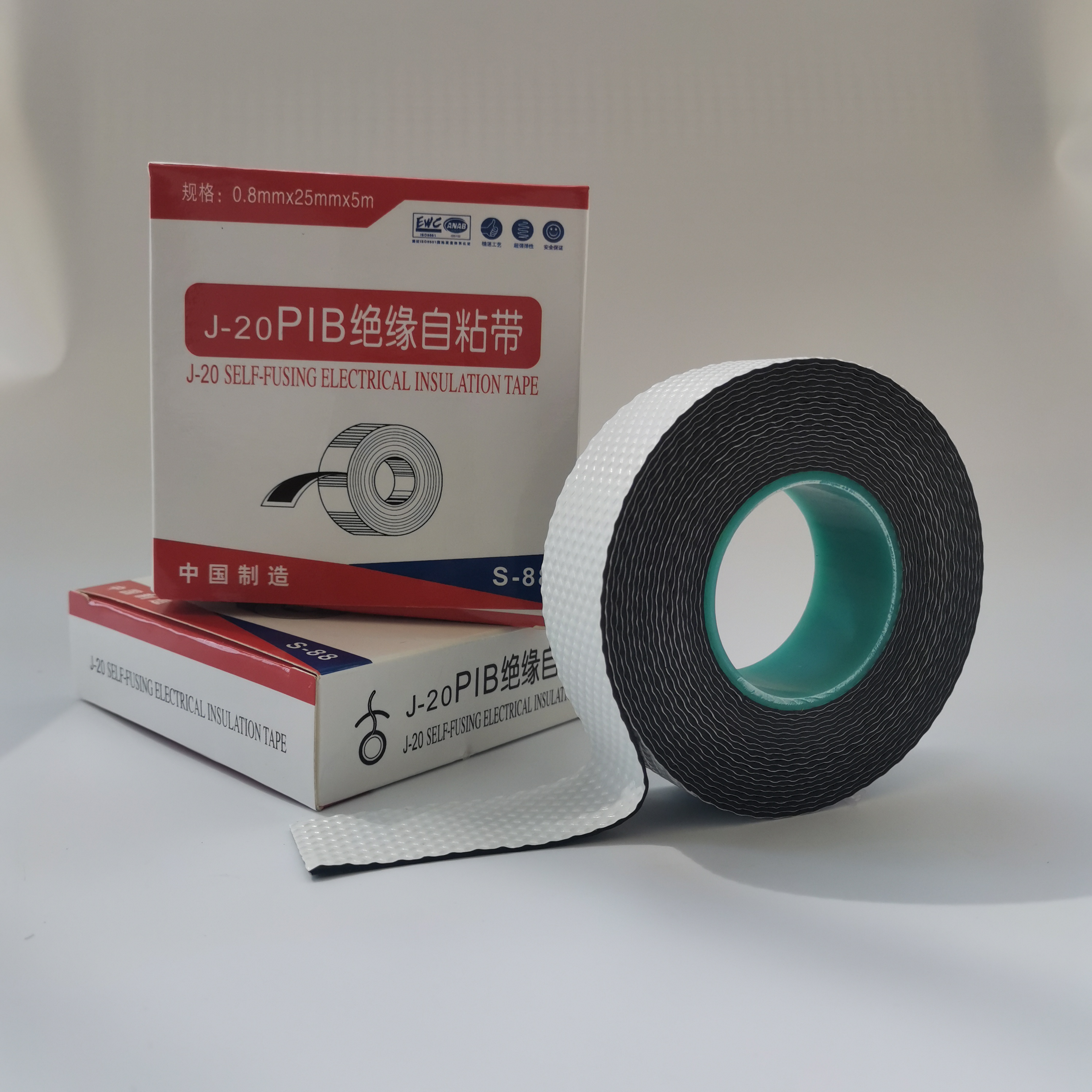

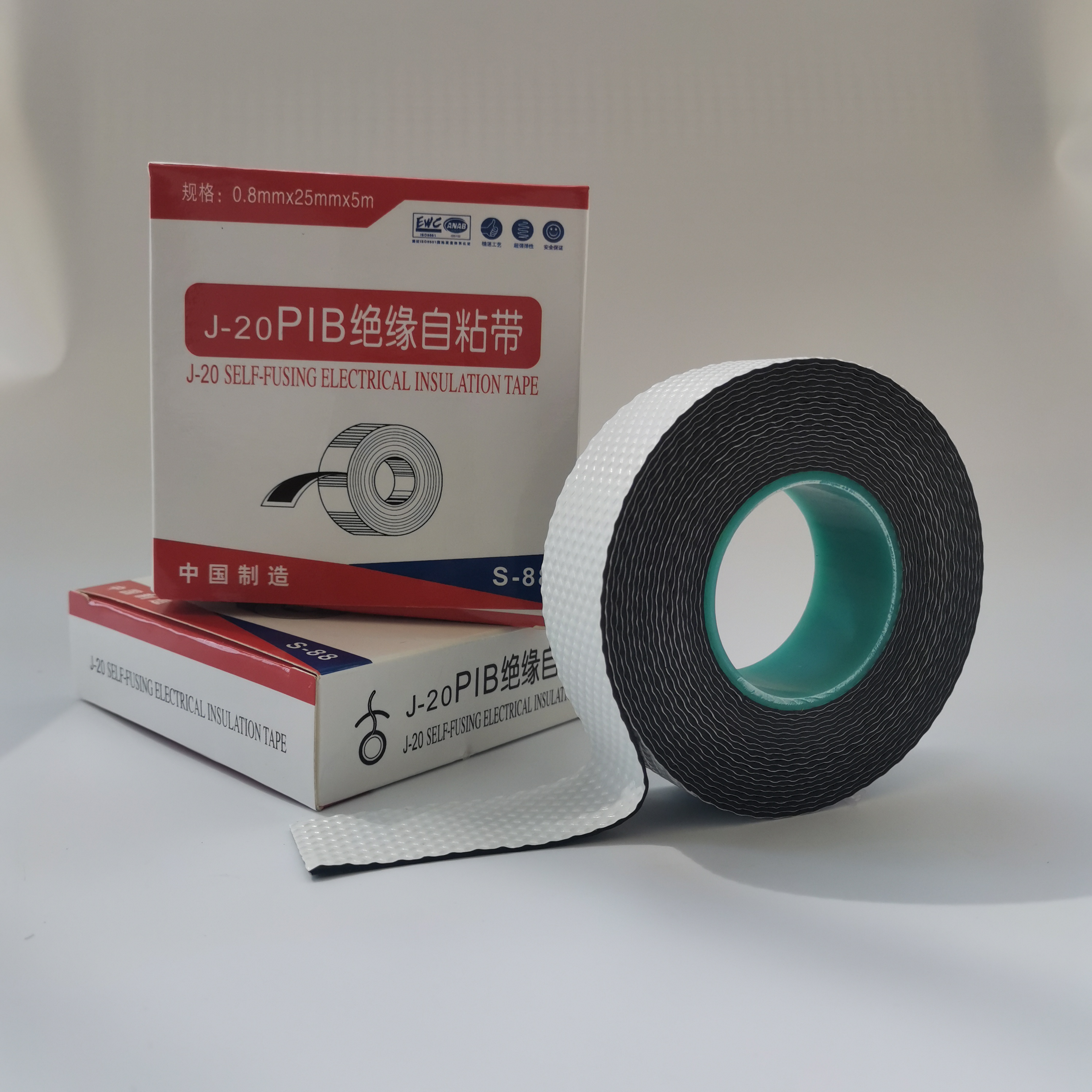

insulation tape yellow. It can also be easily trimmed to size using scissors or a utility knife, allowing workers to customize the tape to fit their specific needs.Self-fusing rubber tape is a simple yet powerful solution that addresses various repair and maintenance needs. Its unique properties, including self-adhesion, flexibility, resistance to extreme temperatures, and waterproofing capabilities, make it an indispensable resource for both professionals and DIY enthusiasts. Whether you are looking to fix a leaky pipe, insulate electrical wires, or bundle tools, self-fusing rubber tape offers an efficient and reliable option that stands the test of time. With its growing popularity, this remarkable tape is poised to become a staple in households and industries alike, proving that sometimes the simplest solutions can provide the most significant benefits.

The Versatility of Self-Adhesive Insulation Tape

How much does silicone tape cost?

Conclusion

Types of Adhesives

Elite Tape offers an extensive line of single coated film tapes with a variety of film backings and adhesive systems. Our polyester-silicone tapes are used for splicing silicone coated papers and high temperature masking applications. We offer these in different colors and different thickness’ depending on your application needs. We also offer polyester-acrylic tapes, polyimide-silicone, polyester-acrylic and polyethylene-rubber. All of these products can be procesed in long length machine rolls for continuous processing. We also offer these tapes die-cut in different designs and configurations. There are several applications requiring our single coated film tapes:

Pump control boxes are responsible for monitoring the flow of water and controlling a water pump to keep it at the desired level. Pump control can vary depending on the type of control box that is installed.

Another type of splicing tape is the magnetic tape. This tape is used in the editing process to align audio tracks with visual footage. By using magnetic splicing tape, editors can synchronize sound effects, music, and dialogue with the corresponding scenes, creating a cohesive and engaging film soundtrack.

splicing tape