warman slurry pump bearing assembly factories

Latest articles

The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

warman slurry pump bearing assembly factories...

warman slurry pump bearing assembly factories 【warman slurry pump bearing assembly factories】

Read MoreWhat style of pump is suitable?

warman slurry pump bearing assembly factories...

warman slurry pump bearing assembly factories 【warman slurry pump bearing assembly factories】

Read MoreExpertise and experience

warman slurry pump bearing assembly factories...

warman slurry pump bearing assembly factories 【warman slurry pump bearing assembly factories】

Read MoreHigh head (i.e. the height to which the pump can move the liquid)

warman slurry pump bearing assembly factories...

warman slurry pump bearing assembly factories 【warman slurry pump bearing assembly factories】

Read MoreTL FGD Pump

warman slurry pump bearing assembly factories...

warman slurry pump bearing assembly factories 【warman slurry pump bearing assembly factories】

Read MoreThe rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

warman slurry pump bearing assembly factories...

warman slurry pump bearing assembly factories 【warman slurry pump bearing assembly factories】

Read MoreAs new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

warman slurry pump bearing assembly factories...

warman slurry pump bearing assembly factories 【warman slurry pump bearing assembly factories】

Read MoreSlurry Pump Considerations

warman slurry pump bearing assembly factories...

warman slurry pump bearing assembly factories 【warman slurry pump bearing assembly factories】

Read MoreHeavy-Duty Slurry Pump

warman slurry pump bearing assembly factories...

warman slurry pump bearing assembly factories 【warman slurry pump bearing assembly factories】

Read MoreAier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

warman slurry pump bearing assembly factories...

warman slurry pump bearing assembly factories 【warman slurry pump bearing assembly factories】

Read More

Popular articles

- Pumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

- Slurry Pump

- When flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

- Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

- - Pumping media where abrasive particles are present

- Will solids size pass through the pump?

Latest articles

-

Selecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

-

A , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

-

On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

-

Quenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

-

Dry Installation

-

- By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

Links

- Perhaps one of the most significant benefits of cloth wiring harness tape is its versatility. It can be used in a wide range of applications, including automotive, aerospace, industrial, and consumer electronics. Whether you need to route wires in a car engine compartment, secure cables in an aircraft cabin, or organize wires in a home theater system, cloth wiring harness tape has the right solution for you.

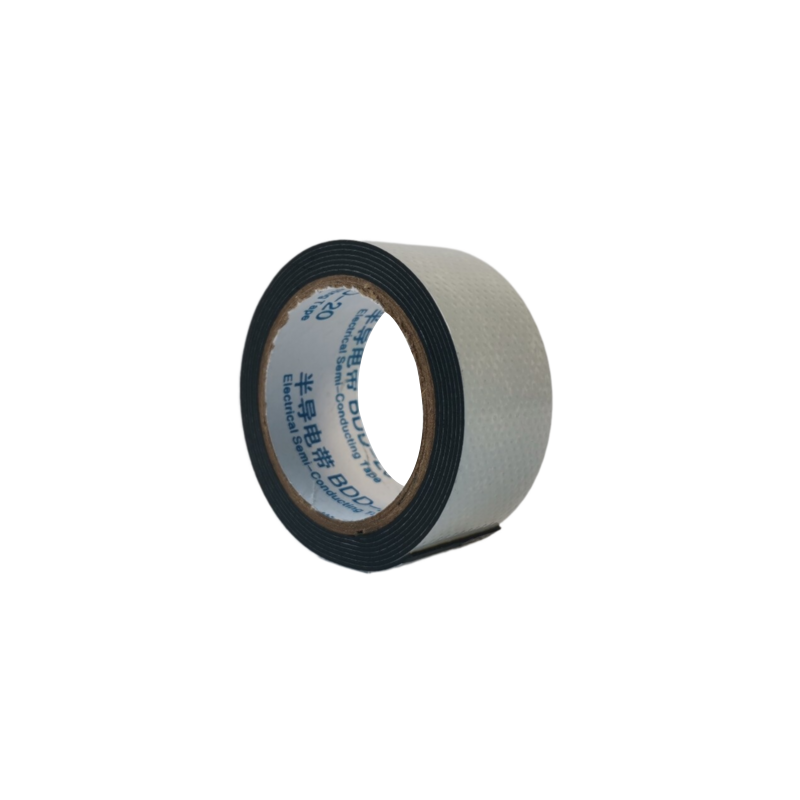

It has an abrasion-resistant backing that lasts long and has flexibility, which makes it a prime option for insulating electrical connections during electrical tapping.

waterproof door seal strip. A tight seal around the door prevents sound from traveling through the gaps, creating a quieter and more peaceful environment. This can be particularly beneficial for homes or buildings located in noisy neighborhoods or areas with high traffic.

Beyond electrical applications, self-adhesive insulation tape proves invaluable in home improvement projects. It is commonly used to seal gaps and cracks in windows and doors, providing an added layer of insulation that can significantly reduce energy costs. Homeowners can utilize this tape to fix leaky pipes temporarily or insulate air conditioners during the off-season. Its versatility allows it to adhere to different materials such as wood, metal, and plastic, making it a go-to solution for various repairs around the house.

Another significant benefit of silicone insulation tape is its ease of use. It can be applied quickly and effectively, even by those who may not have extensive technical expertise. The tape can be torn by hand, eliminating the need for scissors, which is convenient for quick repairs and adjustments. Its lightweight design and compact nature make it easy to carry in toolkits, ensuring that it’s readily available whenever needed.

On the other hand, duct tape is a cloth-backed pressure-sensitive tape made of a thin polyethylene-coated cloth with fibers and a rubber-based adhesive on the other. This composition makes duct tape extremely durable, water-resistant, and great for a wide range of applications.

Goodman is a technical service engineer and Brown is a technical service senior engineer with 3M in Austin, Texas.

self fusing rubber tape. Once applied, it can withstand years of wear and tear without losing its adhesive properties. This makes it a cost-effective solution for long-lasting repairs and installations.

This variety also enables artists to experiment with different styles and techniques, fostering creativity and innovation This variety also enables artists to experiment with different styles and techniques, fostering creativity and innovation

This variety also enables artists to experiment with different styles and techniques, fostering creativity and innovation This variety also enables artists to experiment with different styles and techniques, fostering creativity and innovation flex tape 12 x 10.

flex tape 12 x 10.PVC insulation tape is ideal for low voltage applications. It has various uses which include: insulation, sealing, maintenance, protection, fixing and colour-coding. Our PVC Insulation Tape is available in an assortment of colours to facilitate colour-coding for safety and identification purposes.

Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications

Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications arc proof tape.

arc proof tape.PVC insulation tape uses

pvc hazard tape. It can withstand exposure to a wide range of chemicals, including acids, bases, solvents, and oils, making it an ideal choice for environments where chemicals are present. This characteristic ensures that the tape maintains its integrity and effectiveness over time, even in harsh conditions.

pvc hazard tape. It can withstand exposure to a wide range of chemicals, including acids, bases, solvents, and oils, making it an ideal choice for environments where chemicals are present. This characteristic ensures that the tape maintains its integrity and effectiveness over time, even in harsh conditions.Silicone tape is also fast and easy to apply, and remove. It leaves no sticky residue, so it saves you time cleaning.

Butyl Rubber Tape

several types of polyethylene film tape in various thicknesses and densities. Tape thickness is measured in mils — one mil is one one-thousandth of an inch. Simply choose the tape that works best for your application.

What are Rubber Based Adhesives?

Its resistance to extreme temperatures and harsh environmental conditions makes it a go-to material for aerospace applications Its resistance to extreme temperatures and harsh environmental conditions makes it a go-to material for aerospace applications

Its resistance to extreme temperatures and harsh environmental conditions makes it a go-to material for aerospace applications Its resistance to extreme temperatures and harsh environmental conditions makes it a go-to material for aerospace applications butyl tape rubber.

butyl tape rubber.