subsea dredge pump factories

Latest articles

Is the discharge configuration suitable for abrasive slurries?

subsea dredge pump factories...

subsea dredge pump factories 【subsea dredge pump factories】

Read MoreMake sure you follow the basic rules of pump piping.

subsea dredge pump factories...

subsea dredge pump factories 【subsea dredge pump factories】

Read MorePumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

subsea dredge pump factories...

subsea dredge pump factories 【subsea dredge pump factories】

Read MoreMonitoring

subsea dredge pump factories...

subsea dredge pump factories 【subsea dredge pump factories】

Read MoreTo find out more about Aier slurry Pumps, please >contact us.

subsea dredge pump factories...

subsea dredge pump factories 【subsea dredge pump factories】

Read More>Dredge Pump

subsea dredge pump factories...

subsea dredge pump factories 【subsea dredge pump factories】

Read MoreIf youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

subsea dredge pump factories...

subsea dredge pump factories 【subsea dredge pump factories】

Read MoreAnother way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

subsea dredge pump factories...

subsea dredge pump factories 【subsea dredge pump factories】

Read MoreCaution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

subsea dredge pump factories...

subsea dredge pump factories 【subsea dredge pump factories】

Read MoreSettling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

subsea dredge pump factories...

subsea dredge pump factories 【subsea dredge pump factories】

Read More

Popular articles

- sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- >Slurry Pump

- Better safety

- As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

- Submersible Slurry Pump

- Dry Installation

Latest articles

-

The Difference Between Flushing And Quenching in Slurry Pump Seals

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

-

To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

-

Light-duty Slurry Pump

-

- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

-

Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

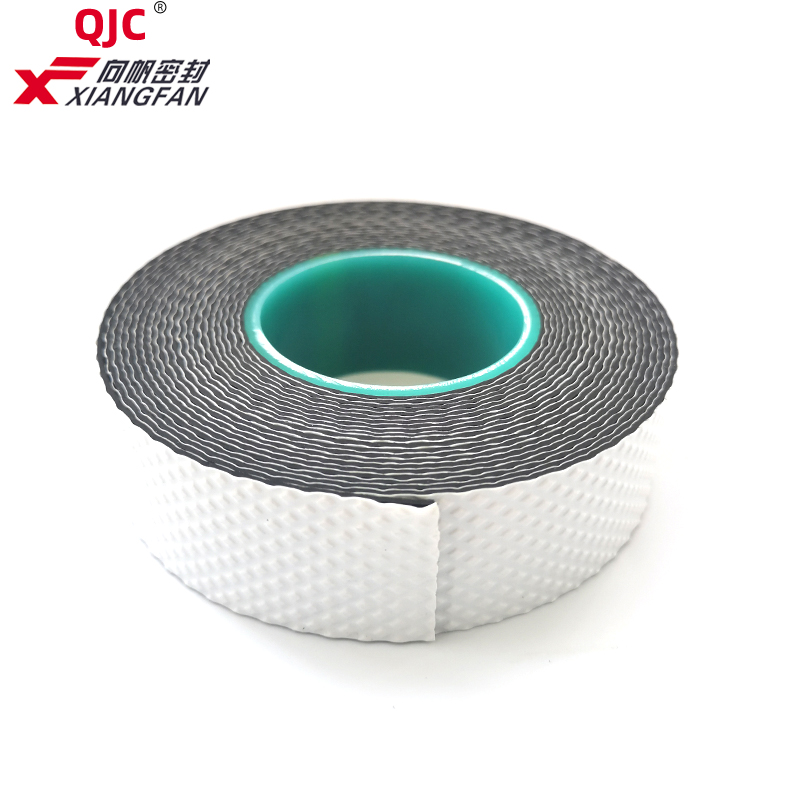

So what is butyl tape, and what are its uses? Read on to find out everything you need to know about this versatile material.

Decide how you would like to control the pump so you can select a control box that is compatible with your desired choice.

Moreover, the clean and neutral appearance of white tape makes it an ideal choice for aesthetic repairs. When a visible repair is necessary, using white tape can provide a cleaner, more discreet solution compared to more colorful alternatives. This can be particularly important in home décor or when maintaining the appearance of household items.

rubber tape to stop water leaks. It is commonly used to repair plumbing pipes, seal windows and doors, and patch up holes and cracks in walls. Its versatility and ease of use make it a must-have item for any DIY enthusiast or homeowner.

Operator Devices

Its high shear strength makes window glazing tape a good option for mounting on vertical surfaces. It has good resistance to humidity, acid, oils, and grease. As a polyethylene foam tape, it has excellent conformability, even conforming to rough or uneven surfaces.

What is Butyl Rubber Sealant Tape?

4. Neoprene Rubber Tape: Neoprene rubber tape is a versatile material that is suitable for a wide range of applications. It is known for its resistance to heat, oil, and chemicals, which makes it ideal for automotive and industrial applications.

A well pump control box is basically the brain of a water system because it handles many tasks to keep the system functioning properly.

Durability and longevity: Silicone rubber tapes offer excellent longevity and toughness, making them a reliable choice for long-term repairs. Rubber repair tapes, on the other hand, offer durability and flexibility, making them ideal for a variety of repair tasks.

Surface Features

One of the primary uses of amalgamating rubber tape is in the electrical industry. Electricians rely on this tape to provide insulation and protection for electrical connections and wires. The tape can be easily stretched and wrapped around the exposed wires, creating a tight and secure seal that prevents moisture and dirt from compromising the connection. Additionally, the tape's elasticity allows it to expand and contract with the wires, ensuring a long-lasting and reliable solution.

self fusing rubber tape. Once applied, it can withstand years of wear and tear without losing its adhesive properties. This makes it a cost-effective solution for long-lasting repairs and installations.

Furthermore, Flex Tape is not just limited to repairs. Its waterproof and strong adhesive qualities make it a fantastic tool for creative projects as well. Crafters and DIY enthusiasts often use it to create waterproof boxes, custom storage solutions, and even innovative home decor items. The tape’s clear finish allows for a professional look, ensuring that your creations are aesthetically pleasing while remaining functional.

Polyethylene Tape’s versatility, durability, moisture resistance, and ease of use make it a valuable tool in various industries, including packaging, construction, plumbing, electrical, and sports. Its applications are extensive, ranging from surface protection to sealing, marking, and repair tasks.

What is Polyethylene Tape used for?

4. Versatility Besides electrical insulation, high voltage self-fusing rubber tape has numerous applications, ranging from automotive repairs to plumbing and HVAC systems. Its ability to conform to various shapes and surfaces makes it an invaluable tool for both electrical and mechanical repairs.

high voltage self fusing rubber tape