china rubber impeller for slurry pump manufacturer

Latest articles

Positive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

china rubber impeller for slurry pump manufacturer...

china rubber impeller for slurry pump manufacturer 【china rubber impeller for slurry pump manufacturer】

Read MoreIf you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

china rubber impeller for slurry pump manufacturer...

china rubber impeller for slurry pump manufacturer 【china rubber impeller for slurry pump manufacturer】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

china rubber impeller for slurry pump manufacturer...

china rubber impeller for slurry pump manufacturer 【china rubber impeller for slurry pump manufacturer】

Read MoreTypes of slurry pump installation.

china rubber impeller for slurry pump manufacturer...

china rubber impeller for slurry pump manufacturer 【china rubber impeller for slurry pump manufacturer】

Read MoreSlurry pump power adjustment

china rubber impeller for slurry pump manufacturer...

china rubber impeller for slurry pump manufacturer 【china rubber impeller for slurry pump manufacturer】

Read More- Low noise level - Operating underwater results in low noise or even silent operation.

china rubber impeller for slurry pump manufacturer...

china rubber impeller for slurry pump manufacturer 【china rubber impeller for slurry pump manufacturer】

Read MoreWhat is the best seal arrangement for the application?

china rubber impeller for slurry pump manufacturer...

china rubber impeller for slurry pump manufacturer 【china rubber impeller for slurry pump manufacturer】

Read MoreI hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

china rubber impeller for slurry pump manufacturer...

china rubber impeller for slurry pump manufacturer 【china rubber impeller for slurry pump manufacturer】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

china rubber impeller for slurry pump manufacturer...

china rubber impeller for slurry pump manufacturer 【china rubber impeller for slurry pump manufacturer】

Read More>Slurry Pump

china rubber impeller for slurry pump manufacturer...

china rubber impeller for slurry pump manufacturer 【china rubber impeller for slurry pump manufacturer】

Read More

Popular articles

- It is important that the pump you choose has components that will not wear out from abrasive slurries.

- Some models can generate discharge pressures up to 260 ft. (80 m).

- Dredge pumps are designed to transfer large quantities of fluids and solids.

- The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

- Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

- >Dredge Pump

Latest articles

-

Slurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

-

Determine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

-

As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

-

1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

-

Slurry Pump

-

How much solids damage can the customer tolerate?

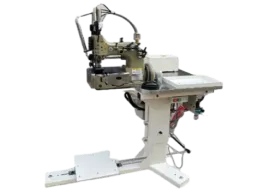

In addition, the ability to adjust the tension of both threads allows for customization, ensuring the perfect stitch for every fabric and design In addition, the ability to adjust the tension of both threads allows for customization, ensuring the perfect stitch for every fabric and design

In addition, the ability to adjust the tension of both threads allows for customization, ensuring the perfect stitch for every fabric and design In addition, the ability to adjust the tension of both threads allows for customization, ensuring the perfect stitch for every fabric and design

It has been discovered that heavy-duty

It has been discovered that heavy-duty