china slurry pump parts expeller

Latest articles

reduce the discharge pressure of the pump to the lowest possible point, and.

china slurry pump parts expeller...

china slurry pump parts expeller 【china slurry pump parts expeller】

Read MoreChoosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

china slurry pump parts expeller...

china slurry pump parts expeller 【china slurry pump parts expeller】

Read MorePumping slurry can cause excessive wear and tear on the pump and its components as the mud can clog the suction and discharge lines.

china slurry pump parts expeller...

china slurry pump parts expeller 【china slurry pump parts expeller】

Read MoreSlurry Pump

china slurry pump parts expeller...

china slurry pump parts expeller 【china slurry pump parts expeller】

Read MoreTypes of damage to slurry pumps

china slurry pump parts expeller...

china slurry pump parts expeller 【china slurry pump parts expeller】

Read MoreFollow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

china slurry pump parts expeller...

china slurry pump parts expeller 【china slurry pump parts expeller】

Read MoreFrom an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

china slurry pump parts expeller...

china slurry pump parts expeller 【china slurry pump parts expeller】

Read MoreThe basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

china slurry pump parts expeller...

china slurry pump parts expeller 【china slurry pump parts expeller】

Read MoreTypes of damage to slurry pumps

china slurry pump parts expeller...

china slurry pump parts expeller 【china slurry pump parts expeller】

Read MoreSlurry Pump

china slurry pump parts expeller...

china slurry pump parts expeller 【china slurry pump parts expeller】

Read More

Popular articles

- The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

- >Slurry Pump

- Carbon transfer

- Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

- As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

- With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

Latest articles

-

Other manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

-

target=_blank>Slurry Pump

-

Slurry pump design

-

>Slurry Pump

-

>Vertical Slurry Pump

-

Includes a large number of solids or particles.

Links

- Hotel sheets are an essential element in creating a comfortable and luxurious experience for guests. The quality of the sheets can greatly impact the overall impression of a hotel stay, and it is important for hoteliers to carefully consider the type of sheets they provide to their guests.

- In terms of maintenance, the plush cooling comforter is designed with convenience in mind. Most models are machine washable, ensuring ease of care without compromising on durability. They resist allergens and dust mites, making them an ideal choice for allergy sufferers or those seeking a hypoallergenic sleeping solution.

Cooling

Bamboo Bedsheets

A higher fill power ensures the insert retains its loft, maintaining its shape and providing consistent warmth over time A higher fill power ensures the insert retains its loft, maintaining its shape and providing consistent warmth over time

A higher fill power ensures the insert retains its loft, maintaining its shape and providing consistent warmth over time A higher fill power ensures the insert retains its loft, maintaining its shape and providing consistent warmth over time plain duvet insert. For a lightweight option, a fill power between 400-500 is suitable, while a heavier warmth would require a fill power of 600 or above.

plain duvet insert. For a lightweight option, a fill power between 400-500 is suitable, while a heavier warmth would require a fill power of 600 or above.There are many options to consider when choosing the perfect high quality bedding for your bedroom. From linen and silk to bamboo and 100% cotton, each type of high quality bedding has its own unique benefits and features. Understanding the differences between these different types of high quality bedding can help you make an informed decision that suits your personal preferences and needs.

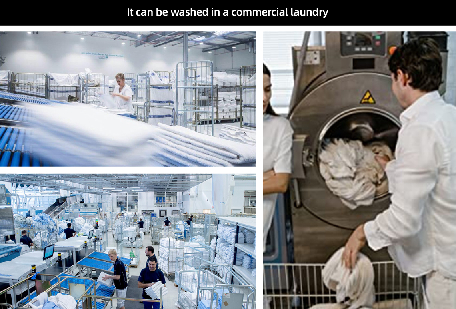

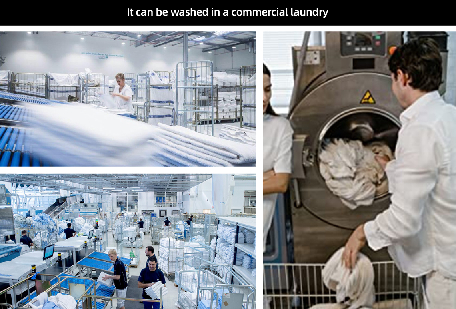

This is essential for boutique hotels, where guest turnover is typically higher than in larger chain hotels, and the bed linen needs to be able to withstand multiple washings and still look and feel as good as new This is essential for boutique hotels, where guest turnover is typically higher than in larger chain hotels, and the bed linen needs to be able to withstand multiple washings and still look and feel as good as new

This is essential for boutique hotels, where guest turnover is typically higher than in larger chain hotels, and the bed linen needs to be able to withstand multiple washings and still look and feel as good as new This is essential for boutique hotels, where guest turnover is typically higher than in larger chain hotels, and the bed linen needs to be able to withstand multiple washings and still look and feel as good as new boutique hotel bed linen.

boutique hotel bed linen. It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details

It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details plain towel. This practicality makes it a favorite among busy households and those who appreciate the ease of maintenance.

plain towel. This practicality makes it a favorite among busy households and those who appreciate the ease of maintenance.Bedding Design

The fill offers exceptional insulation without being too heavy, striking the perfect balance between warmth and breathability The fill offers exceptional insulation without being too heavy, striking the perfect balance between warmth and breathability

The fill offers exceptional insulation without being too heavy, striking the perfect balance between warmth and breathability The fill offers exceptional insulation without being too heavy, striking the perfect balance between warmth and breathability puffy duvet insert. It traps just the right amount of body heat to keep you warm on chilly nights while allowing air to circulate, preventing overheating during warmer months.

puffy duvet insert. It traps just the right amount of body heat to keep you warm on chilly nights while allowing air to circulate, preventing overheating during warmer months.As polyester is made from a petrochemical, it's not biodegradable like natural untreated fabrics. It can also shed plastic microfibres when washed which can end up in our rivers and seas.

They can be used in a variety of settings, including guest rooms, dormitories, and even as a travel companion They can be used in a variety of settings, including guest rooms, dormitories, and even as a travel companion

They can be used in a variety of settings, including guest rooms, dormitories, and even as a travel companion They can be used in a variety of settings, including guest rooms, dormitories, and even as a travel companion cotton down alternative comforter. Their lightweight and compressible nature make them easy to pack and transport, making them an ideal choice for those who frequently travel or move.

cotton down alternative comforter. Their lightweight and compressible nature make them easy to pack and transport, making them an ideal choice for those who frequently travel or move.7. Bamboo

Caring for your linen bed sheets is also easy. Wash them in cold water with mild detergent and tumble low dry. If you plan on ironing them, a good tip is to take them out of the dryer when they are slightly damp and iron on low heat.