china vertical sump pump parts manufacturers

Latest articles

Dredge Pump

china vertical sump pump parts manufacturers...

china vertical sump pump parts manufacturers 【china vertical sump pump parts manufacturers】

Read MoreA slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

china vertical sump pump parts manufacturers...

china vertical sump pump parts manufacturers 【china vertical sump pump parts manufacturers】

Read MoreIf a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

china vertical sump pump parts manufacturers...

china vertical sump pump parts manufacturers 【china vertical sump pump parts manufacturers】

Read MoreA slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

china vertical sump pump parts manufacturers...

china vertical sump pump parts manufacturers 【china vertical sump pump parts manufacturers】

Read MoreDepending on the abrasive nature of the slurry, it is important to select the ideal seal. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. Vortex pumps use patented seal technology that utilizes a double mechanical seal setup and a separate seal flushing system. This allows the sealing surface to be kept cool at all times without causing the slurry to overheat the seal and crack the surface.

china vertical sump pump parts manufacturers...

china vertical sump pump parts manufacturers 【china vertical sump pump parts manufacturers】

Read MoreFind the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

china vertical sump pump parts manufacturers...

china vertical sump pump parts manufacturers 【china vertical sump pump parts manufacturers】

Read MoreChoosing the Right Pump for Flue Gas Desulphurisation

china vertical sump pump parts manufacturers...

china vertical sump pump parts manufacturers 【china vertical sump pump parts manufacturers】

Read More1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

china vertical sump pump parts manufacturers...

china vertical sump pump parts manufacturers 【china vertical sump pump parts manufacturers】

Read MoreA typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

china vertical sump pump parts manufacturers...

china vertical sump pump parts manufacturers 【china vertical sump pump parts manufacturers】

Read MoreHorizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

china vertical sump pump parts manufacturers...

china vertical sump pump parts manufacturers 【china vertical sump pump parts manufacturers】

Read More

Popular articles

- As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

- There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

- Centrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

- As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

- Customised solutions

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

Latest articles

-

Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

-

Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

-

Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

-

Selecting And Operating A Slurry Pump

-

Consider the following.

-

>Slurry Pump vs Mud Pump

Links

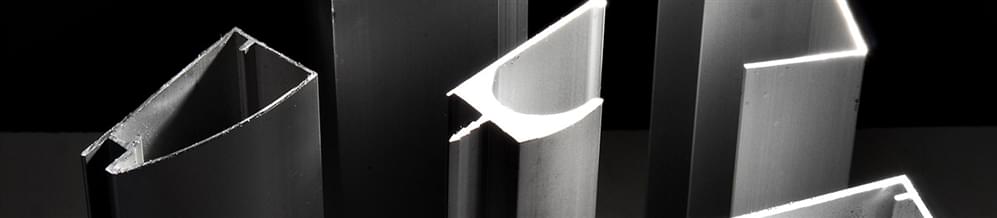

Aluminium Windows Profiles

Design And Shape

Sliding doors are an attractive and functional addition to any home, offering a seamless transition between indoor and outdoor spaces. However, like all moving parts, the rollers on sliding doors can wear out or become misaligned over time. If you're experiencing difficulty in opening or closing your sliding door, it might be time to adjust the rollers. In this guide, we will explore the steps necessary to adjust sliding door rollers, ensuring smooth operation and extending the lifespan of your door.

The performance of windows and doors depending on the range of use, but the following aspects are usually considered: strength, which is mainly reflected in the selection of materials for windows and doors, whether it can withstand ultra-high pressure; air tightness, mainly in the structure of windows and doors, whether the inner and outer frames of the windows and doors are tight, and the doors and windows are tight.

In addition to its use in the garden or as art, wrought iron can be employed in more functional roles, such as building items like shelving units or brackets. These can add both utility and a rustic or industrial aesthetic to your home environment.

For starters, things can serve a practical purpose in our lives. From the moment we wake up in the morning, we interact with a multitude of things that help us navigate through our day. We use utensils to eat our breakfast, a toothbrush to clean our teeth, and a car to commute to work. Without these things, our daily routines would be much more difficult and inefficient.

While rod iron scrolls are celebrated for their decorative purposes, they also serve practical functions. When used in fencing or railing applications, they provide security without compromising on style. The open design of scrollwork allows for visibility and light while maintaining a boundary. This is particularly appealing in outdoor spaces, such as gardens and patios, where beauty, safety, and practicality must coexist.

Fence Post

The only real drawback is that this is not a suitable material for a privacy fence, but that is the case with nearly all metal fences.

After special finishing operations, you may cut the profiles into shorter lengths depending on the actual dimensions of the windows and doors. While at it, you may use special devices to clamp the profiles, cut and transfer them to a conveyor.

Technically, making aluminum profiles for windows and doors involves altering most of its physical characteristics. However, definitive cross-sections are introduced in the profile to boost its versatility.

Metal taps, commonly made from materials like brass, stainless steel, or aluminum, are known for their strength and longevity. The robustness of metal ensures that these taps can withstand higher pressures and temperatures, making them suitable for a broader range of applications. In industrial settings, for example, metal taps are often utilized in pipelines carrying heavy liquids, where durability and reliability are paramount.

Types of Rollers

One of the key advantages of cast iron ornaments is their durability. Made from a material known for its strength and resilience, these decorations can withstand the elements and remain in good condition for many years. This makes them an excellent choice for outdoor use, where they can add beauty to a garden or patio without the risk of damage from rain, wind, or sun exposure.

Both types of iron are highly recyclable, which adds to their sustainability. At the end of their life cycle, iron fences can be melted down and reused, reducing the need for new raw materials and minimizing waste.

I. Types of aluminum profiles for doors and windows:

Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures

Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures Today, while their presence may be less common, they still retain an undeniable aesthetic value that is highly sought after by designers looking to imbue a sense of history and timelessness into modern structures cast iron post collars.

cast iron post collars.

metal key storage box. This means that they can withstand heavy usage and remain in good condition for many years.