high quality sand dredge pump 8 factories

Latest articles

Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

high quality sand dredge pump 8 factories...

high quality sand dredge pump 8 factories 【high quality sand dredge pump 8 factories】

Read MoreAs wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

high quality sand dredge pump 8 factories...

high quality sand dredge pump 8 factories 【high quality sand dredge pump 8 factories】

Read MoreMaterials of Construction

high quality sand dredge pump 8 factories...

high quality sand dredge pump 8 factories 【high quality sand dredge pump 8 factories】

Read MoreIf the exact in-pump viscosity of the product is unknown, CSI can help

high quality sand dredge pump 8 factories...

high quality sand dredge pump 8 factories 【high quality sand dredge pump 8 factories】

Read MoreSelecting a dredge pump

high quality sand dredge pump 8 factories...

high quality sand dredge pump 8 factories 【high quality sand dredge pump 8 factories】

Read MoreWhen slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

high quality sand dredge pump 8 factories...

high quality sand dredge pump 8 factories 【high quality sand dredge pump 8 factories】

Read MoreIf you want to know more information about the best slurry pumps wholesale, welcome to >contact us today or request a quote.

high quality sand dredge pump 8 factories...

high quality sand dredge pump 8 factories 【high quality sand dredge pump 8 factories】

Read MoreA >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

high quality sand dredge pump 8 factories...

high quality sand dredge pump 8 factories 【high quality sand dredge pump 8 factories】

Read MoreIncludes a large number of solids or particles.

high quality sand dredge pump 8 factories...

high quality sand dredge pump 8 factories 【high quality sand dredge pump 8 factories】

Read More- Pumping media where abrasive particles are present

high quality sand dredge pump 8 factories...

high quality sand dredge pump 8 factories 【high quality sand dredge pump 8 factories】

Read More

Popular articles

- >Slurry Pump

- In this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

- - Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

- The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

Latest articles

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

-

Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

-

>Slurry Pump

-

Magnetite mixing

-

For more information about this new and improved pump, please contact us.

-

On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

Furthermore, the design of dustbins has evolved with technology. Innovative solutions, such as smart dustbins equipped with sensors, can alert waste management services when they are full. This technology not only streamlines waste collection but also minimizes the carbon footprint by optimizing collection routes and reducing unnecessary trips. With the growing emphasis on sustainability, incorporating such technology into municipal waste management systems can greatly enhance operational efficiency and effectiveness.

3. Slip Resistance Rating Refer to industry standards for slip resistance. Manufacturers typically provide ratings that indicate how well a cover will perform under wet conditions.

Sustainability Considerations

Conclusion

One of the primary advantages of dustbin chutes is their ability to streamline the waste disposal process. In high-rise buildings, residents often face the cumbersome task of carrying bags of waste down multiple flights of stairs or waiting for elevators, which can be time-consuming and inconvenient. By installing dustbin chutes, vertical waste disposal becomes effortless. Residents can simply drop their bags down the chute, ensuring quick and easy disposal without the hassle of carrying it around.

dustbin chute

While inset manhole lids offer various advantages, there are also considerations for city planners and engineers. Installation costs can be higher due to the need for precise alignment and additional materials. Furthermore, ongoing maintenance is essential to prevent issues related to settling or misalignment over time, which can compromise the functionality and safety of the lid.

The 3% Dustbin A Shift Towards Sustainable Waste Management

Versatility and Compatibility

single bike hitch rack

Furthermore, these covers are designed to fit securely into their frames, preventing water, debris, and even wildlife from entering the underground systems. This sealing function is particularly important in urban areas where flooding can cause severe infrastructure damage and disrupt daily life. A well-placed and designed manhole cover ensures that the urban drainage system operates efficiently, protecting the city from excessive rainwater accumulation and its negative effects.

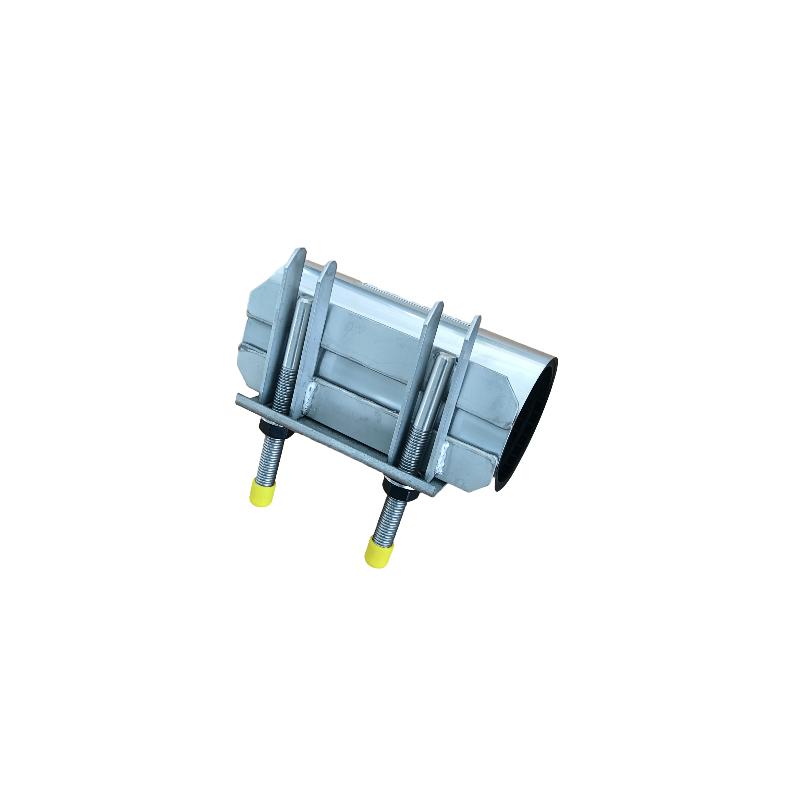

Understanding Water Pipe Repair Clamps A Guide to Efficient Pipe Repair

At the core of square grating design is the principle of diffraction. When light encounters a square grating, it bends around the edges of the apertures, causing interference patterns to form. The arrangement of the squares, their size, and the spacing between them all play critical roles in determining how light is diffracted. This interaction is governed by the grating equation, which relates the angle of diffraction to the wavelength of light and the spacing of the elements in the grating.

To ensure the longevity and reliability of gate valve wheels, routine maintenance is essential. This includes regular inspections for signs of wear, corrosion, or damage. Lubrication may be required to reduce friction and facilitate smoother operation. Operators should also be trained to recognize the signs of a malfunctioning valve wheel, such as difficulty in turning or unusual noises during operation.

Ground-embedded bollards serve multiple roles in modern urban design, promoting safety, defining spaces, enhancing aesthetics, and providing versatile functionality. As cities continue to evolve, the effective utilization of these structures will play a crucial role in creating safer, more organized, and visually appealing environments. As they blend seamlessly into the surroundings, ground-embedded bollards exemplify the intersection of functionality and design, making them a vital component of urban infrastructure for the future.

Bollards have become an essential element in urban design and infrastructure, serving various practical and aesthetic purposes. Among the different types of bollards, ground-embedded bollards have gained significant attention for their versatility and effectiveness in enhancing safety and defining spaces. In this article, we will explore the importance and utility of ground-embedded bollards in today's urban environments.

3. Display and Accessibility

In summation, private parking bollards are an essential investment for any property owner looking to enhance security, maintain order, and improve the aesthetic appeal of their parking areas. Their multifaceted functions—ranging from deterring unauthorized access to guiding traffic and creating a visually appealing environment—make them a crucial component in effective parking management. As urban areas continue to grow and evolve, the role of such functional installations will undoubtedly become more pronounced, ensuring that the challenges of space and safety are met with innovative solutions.

A gate valve is a type of valve that opens or closes by lifting a gate out of the path of the fluid. It is designed to allow maximum flow with minimal pressure drop when fully open. The gate valve is typically used for on/off control rather than for regulating flow. The unique design ensures that the flow path is unobstructed when the valve is open, which makes it a preferred choice for systems that require a full flow rate.

Environmental sustainability is another important aspect of stainless steel grating. Stainless steel is 100% recyclable, which means that it can be repurposed at the end of its life cycle, reducing waste and minimizing environmental impact. The longevity of stainless steel products also contributes to sustainability efforts, as they require less frequent replacement than other materials, thereby conserving resources and energy.

This may not be the case with square and rectangular covers that can fall in if placed diagonally while it is being aligned. Circular manhole covers are also easy to roll and put into place.

Conclusion

What is a Steel Gully Grid?

In addition to their practical function, emergency access bollards also serve as a visible deterrent to would-be intruders. The presence of these bollards sends a clear message that the area is secure and that unauthorized vehicles will not be able to enter. This can help to prevent vandalism, theft, or other criminal activities, providing peace of mind to property owners and occupants.

Sameera Building Construction provides insights into the weight variations of these covers, influencing their role as access points for maintenance and repair crews.

In conclusion, the act of lifting drain covers is a vital task that contributes significantly to safety, environmental health, and urban maintenance. While it may seem like a mundane chore, its implications are far-reaching. Regular inspections and prompt maintenance can prevent accidents, mitigate environmental pollution, and foster community involvement. As cities continue to grow and face the challenges of climate change, the importance of maintaining effective drainage systems through diligent care of drain covers cannot be overstated. By recognizing the significance of this simple yet crucial task, we can work towards safer, cleaner, and more resilient urban environments.

The Importance of Attention to Detail The Case of the Missing Manhole Cover

Imagine walking down a sidewalk without any manhole covers; you could accidentally fall into a large and dark hole! We are shielded from the dangers below by the barrier that these covers create. Additionally, they safeguard important underground systems like utility networks and sewer pipes. Thus, manhole covers act as guardians, ensuring the safety and security of us and the infrastructure under our feet.

In conclusion, anti-parking posts are more than just physical barriers—they serve as an integral component of urban planning that promotes safety, organization, and aesthetics. By controlling parking, enhancing pedestrian safety, contributing to urban design, and supporting environmental sustainability, anti-parking posts play a vital role in shaping modern cities. As urban areas continue to grow and develop, the importance of such simple yet effective solutions cannot be overstated, proving that sometimes the smallest changes can lead to significant improvements in our everyday lives.

- Expert Advice The staff at Home Depot can provide invaluable assistance in selecting the right clamp. If you're unsure which product will work best for your specific situation, don’t hesitate to ask for help.

What Are Ground-Embedded Bollards?

In addition, circular manhole covers also offers the advantage of resisting on Earth's compression around it which plainly shows both the technical and practical reason why manhole covers should be design round.

Moreover, these bollard sleeves can be designed to absorb impact, further improving safety features. When a vehicle collides with a bollard equipped with a durable sleeve, the chances of significant damage to both the vehicle and the surrounding infrastructure are dramatically reduced. This impact resistance is essential in busy urban centers where the probability of accidents is higher.

These valves are particularly useful in systems that do not require frequent throttling. For example, in firefighting systems, a gate valve can quickly open to allow water to flow to hoses, and closing it stops the water efficiently without requiring constant adjustment.

In conclusion, while dustbins in restaurants might seem like an unavoidable byproduct of food service, they represent a larger conversation about sustainability in the dining industry. By implementing strategies to minimize waste, from adjusting portion sizes to embracing technology, restaurants can significantly reduce their impact on the environment. This responsibility does not rest solely on the shoulders of restaurant owners; it is a collective effort that requires awareness and action from both businesses and consumers. As we redefine our relationship with food and waste, the transformation from overflowing dustbins to thoughtful waste management can create a more sustainable future for the culinary world.

1. Materials Used

Conclusion

Gate valves are crucial components in a wide array of piping systems, widely utilized in various industries including water treatment, oil and gas, and manufacturing. This article will delve into the specifics of the 1-1/2 inch gate valve, discussing its design, applications, benefits, and maintenance.

Applications

Have you ever wondered: “what is a manhole cover?” A manhole cover is a removable plate used to close off an opening to a confined space such as a sewer, utility access point, or storm drain. They are typically round or rectangular and drop into or sit atop an underlying frame or structure. Manhole covers are often made from cast iron, ductile iron, steel, concrete, composite materials, or plastic.

Moreover, the pharmaceutical industry is also harnessing sensor can technology to enhance drug safety. Many medications require strict adherence to temperature and storage conditions throughout their lifecycle. By placing pharmaceuticals in sensor cans, manufacturers and distributors can track the storage conditions of their products from the point of manufacture to the pharmacy shelf. This not only assures customers of the product's integrity but also helps companies comply with regulatory standards regarding drug safety.

sensor can