china wetted parts for slurry pump factory

Latest articles

It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

china wetted parts for slurry pump factory...

china wetted parts for slurry pump factory 【china wetted parts for slurry pump factory】

Read MoreWhat is a slurry?

china wetted parts for slurry pump factory...

china wetted parts for slurry pump factory 【china wetted parts for slurry pump factory】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

china wetted parts for slurry pump factory...

china wetted parts for slurry pump factory 【china wetted parts for slurry pump factory】

Read MoreHigh head (i.e. the height to which the pump can move the liquid)

china wetted parts for slurry pump factory...

china wetted parts for slurry pump factory 【china wetted parts for slurry pump factory】

Read MoreSlurry Pump

china wetted parts for slurry pump factory...

china wetted parts for slurry pump factory 【china wetted parts for slurry pump factory】

Read MoreFlushing is defined as a fluid which is introduced into the seal cavity on the process fluid side, close to the seal face, and is normally used to cool and lubricate the seal face.

china wetted parts for slurry pump factory...

china wetted parts for slurry pump factory 【china wetted parts for slurry pump factory】

Read MoreTypes of slurry pumps

china wetted parts for slurry pump factory...

china wetted parts for slurry pump factory 【china wetted parts for slurry pump factory】

Read MoreSlurry Pump

china wetted parts for slurry pump factory...

china wetted parts for slurry pump factory 【china wetted parts for slurry pump factory】

Read MoreIf you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

china wetted parts for slurry pump factory...

china wetted parts for slurry pump factory 【china wetted parts for slurry pump factory】

Read MoreLonger maintenance intervals

china wetted parts for slurry pump factory...

china wetted parts for slurry pump factory 【china wetted parts for slurry pump factory】

Read More

Popular articles

- Examples of these dubious enhancements to impeller adjustment abound in the industry. One of these is the adjustable wear ring or suction liner to maintain the recommended clearance between the impeller front shroud and the throat bushing face. Almost all >slurry pumps, including AIER® slurry pumps, have features to ensure that this equipment specification can be maintained over time.

- Slurry pump seals

- Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

- - Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

- The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

- Metal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

Latest articles

-

- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

-

If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

-

Mixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

-

Rubber Lined Slurry Pump

-

Flushing is defined as a fluid which is introduced into the seal cavity on the process fluid side, close to the seal face, and is normally used to cool and lubricate the seal face.

-

Slurry Pump Speed

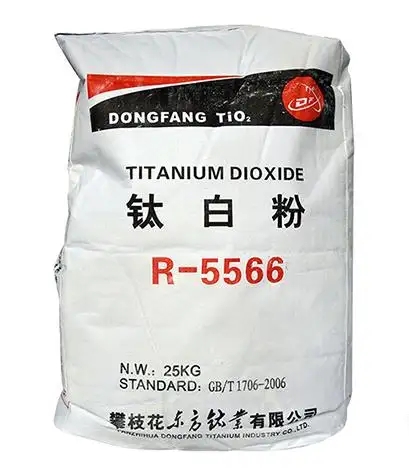

Titanium dioxide, or TiO2, will be listed on product labels, but companies are not required to list ingredient size or structure. When it is used in sunscreens to block UV light, titanium dioxide is considered an active ingredient, which means the concentration must also be listed.

Infrared analysis showed that the characteristics bands for the bare nanoparticles are still exhibited in the vitamins@P25TiO2NPs spectra, such as a wide peak in 450–1028 cm−1 related to the stretching vibration of Ti-O-Ti and other peaks in 1630 cm−1 and 3400 cm−1, which represent the surface OH groups stretching. The IR spectrum of vitaminB2@P25TiO2NPs showed signs of binding between compounds. The OH bending peak (1634 cm−1) corresponding to bare nanoparticles disappeared, and the NH2 bending band characteristic of vitamin B2 appeared (1650 cm−1). The IR spectrum of vitaminC@P25TiO2NPs also showed signs of successful functionalization. Bands at 1075 cm−1; 1120 cm−1; 1141 cm−1 were observed, which are originated by C O-C vibrations present in the vitamin C. The intense band at 1672 cm−1 is attributed to the C = O stretching in the lactone ring while the peak at 1026 cm−1 is ascribed to the stretching vibration Ti-O-C. Wide bands at 3880–3600 cm−1 are related to stretching vibration OH groups, but those disappear in the modified nanoparticles spectrum. These observations confirm the interactions between the P25TiO2NPs and the vitamins [35].

O-C vibrations present in the vitamin C. The intense band at 1672 cm−1 is attributed to the C = O stretching in the lactone ring while the peak at 1026 cm−1 is ascribed to the stretching vibration Ti-O-C. Wide bands at 3880–3600 cm−1 are related to stretching vibration OH groups, but those disappear in the modified nanoparticles spectrum. These observations confirm the interactions between the P25TiO2NPs and the vitamins [35].

Item

We apply titanium dioxide to our skin through sunscreens, makeup, lip balms, nail polish, and other cosmetic products.

R-895 is a paint grade titanium dioxide pigment produced by the chlorination process. Recommended for use in a variety of coating applications.

Health advocates urge US regulators to ban common food coloring additive, by Tom Perkins, The Guardian, June 2, 2023

Tint reducing power, compared with standard samples

The photocatalytic properties of TiO 2 are used in modern technologies. Photo catalysis is the acceleration of a chemical reaction under the influence of light (UV radiation, visible radiation, infrared) in the presence of a photocatalyst. Titanium white appropriately ground to the size of nanoparticles has unique photocatalytic properties and can get from rutile titanium dioxide supplier.

SURFACES, CHEMISTRY & APPLICATIONS

In a 2019 study published in the journal Nanotoxicology, researchers recreated the first phase of digestion in mice and fed them titanium dioxide, then examined whether accumulation occurred in the organs. Researchers wrote: “Significant accumulation of titanium was observed in the liver and intestine of E171-fed mice; in the latter a threefold increase in the number of TiO2 particles was also measured. Titanium accumulation in the liver was associated with necroinflammatory foci containing tissue monocytes/macrophages. Three days after the last dose, increased superoxide production and inflammation were observed in the stomach and intestine. Overall, [this] indicates that the risk for human health associated with dietary exposure to E171 needs to be carefully considered.”

It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality

It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality It can be used to break down organic pollutants in water and air, acting as a green solution for cleaning industrial waste and improving air quality wholesale pigment titanium dioxide. Moreover, when incorporated into building materials, it can decompose pollutants such as nitrogen oxides, potentially reducing smog in urban environments.

wholesale pigment titanium dioxide. Moreover, when incorporated into building materials, it can decompose pollutants such as nitrogen oxides, potentially reducing smog in urban environments.LITHOPONE

The future of TiO2

lithopone b301 b311 pricelist factory. By choosing our factory as your supplier of lithopone B301 and B311, you can rest assured that you are getting great value for your money.

North America