high quality metal liner slurry pump

Latest articles

The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

high quality metal liner slurry pump...

high quality metal liner slurry pump 【high quality metal liner slurry pump】

Read More- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

high quality metal liner slurry pump...

high quality metal liner slurry pump 【high quality metal liner slurry pump】

Read MoreChoosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

high quality metal liner slurry pump...

high quality metal liner slurry pump 【high quality metal liner slurry pump】

Read MoreParticle size, shape and hardness (impact on wear and corrosion potential of pump components)

high quality metal liner slurry pump...

high quality metal liner slurry pump 【high quality metal liner slurry pump】

Read MoreFewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

high quality metal liner slurry pump...

high quality metal liner slurry pump 【high quality metal liner slurry pump】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

high quality metal liner slurry pump...

high quality metal liner slurry pump 【high quality metal liner slurry pump】

Read MoreChoosing The Right Slurry Pump For Your Application

high quality metal liner slurry pump...

high quality metal liner slurry pump 【high quality metal liner slurry pump】

Read MoreMill sump

high quality metal liner slurry pump...

high quality metal liner slurry pump 【high quality metal liner slurry pump】

Read MoreSlurry Pump

high quality metal liner slurry pump...

high quality metal liner slurry pump 【high quality metal liner slurry pump】

Read MoreSettling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

high quality metal liner slurry pump...

high quality metal liner slurry pump 【high quality metal liner slurry pump】

Read More

Popular articles

- Sump drainage or washdown

- Corrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

- From an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

- When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

- - Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

- The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

Latest articles

-

Materials of Construction

-

target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

-

>Slurry Pump

-

Underwater installation

-

If youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

-

Vertical Slurry Pump

Links

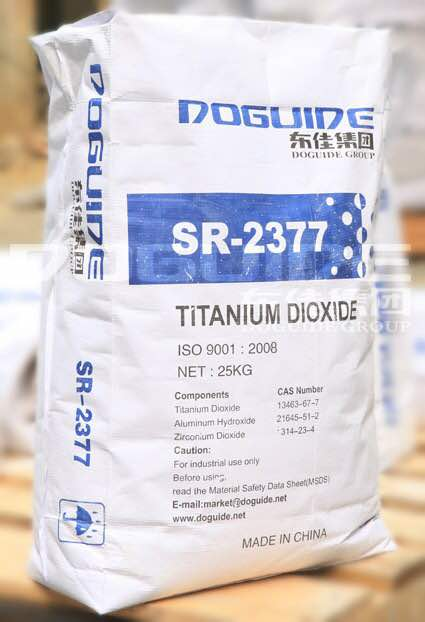

- The wholesale titanium dioxide market has experienced a notable resurgence in recent years, driven by a diverse range of applications and a growing global demand. This report aims to provide a comprehensive overview of the current state of the market, including an analysis of key trends, drivers, and challenges.

- Overall, the use of nano titania in coatings offers a range of benefits, including UV resistance, durability, self-cleaning properties, antimicrobial properties, and improved mechanical properties. As China continues to drive innovation in the coatings industry, the adoption of nano titania in coatings is expected to increase, leading to the development of advanced and sustainable coating solutions.

- Firstly, it is important to consider the supplier's reputation and experience in the industry. A reputable supplier with a long history of providing high-quality titanium dioxide will likely have a good understanding of the specific requirements of ceramic manufacturers and be able to provide customized solutions accordingly.

- The significance of lithopone pigment lies in its ability to enhance product quality while ensuring cost-effectiveness. Its non-toxic nature further cements its position as a preferred choice for manufacturers aiming to align their processes with environmental sustainability standards. The whiteness and chemical stability of lithopone make it a versatile addition to products ranging from cosmetics to high-performance industrial coatings.

The updated evaluation revises the outcome of EFSA’s previous assessment published in 2016, which highlighted the need for more research to fill data gaps.

- In the energy field, ATDNs are being explored as photovoltaic materials and photocatalysts for water splitting

Lithopone - Secondly, the supplier's technical expertise and ability to provide technical support are also crucial factors. Ceramic manufacturers may face various challenges during the production process, such as issues with color consistency or glaze application. A supplier with strong technical capabilities can offer valuable advice and assistance to help resolve these issues.

- In conclusion, titanium dioxide is an integral part of coatings factories, transforming the quality and functionality of coatings. Its role as a pigment not only adds aesthetic appeal but also provides crucial protection against environmental factors. As technology advances, the coatings industry will likely continue to harness the full potential of TiO2, ensuring its continued dominance in the sector.

Price and Availability

Price and Availability It can split water molecules or decompose organic compounds when exposed to light, which is a promising feature for environmental clean-up operations and renewable energy initiatives It can split water molecules or decompose organic compounds when exposed to light, which is a promising feature for environmental clean-up operations and renewable energy initiatives

It can split water molecules or decompose organic compounds when exposed to light, which is a promising feature for environmental clean-up operations and renewable energy initiatives It can split water molecules or decompose organic compounds when exposed to light, which is a promising feature for environmental clean-up operations and renewable energy initiatives This feature is particularly beneficial for coatings used in outdoor environments, as it helps to keep surfaces clean and reduce maintenance costs This feature is particularly beneficial for coatings used in outdoor environments, as it helps to keep surfaces clean and reduce maintenance costs

This feature is particularly beneficial for coatings used in outdoor environments, as it helps to keep surfaces clean and reduce maintenance costs This feature is particularly beneficial for coatings used in outdoor environments, as it helps to keep surfaces clean and reduce maintenance costs