horizontal slurry pump suppliers

Latest articles

A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

horizontal slurry pump suppliers...

horizontal slurry pump suppliers 【horizontal slurry pump suppliers】

Read MoreIf the exact in-pump viscosity of the product is unknown, CSI can help

horizontal slurry pump suppliers...

horizontal slurry pump suppliers 【horizontal slurry pump suppliers】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

horizontal slurry pump suppliers...

horizontal slurry pump suppliers 【horizontal slurry pump suppliers】

Read More2. All have vertical pumps and horizontal pumps and can convey slurry.

horizontal slurry pump suppliers...

horizontal slurry pump suppliers 【horizontal slurry pump suppliers】

Read More>Slurry Pump

horizontal slurry pump suppliers...

horizontal slurry pump suppliers 【horizontal slurry pump suppliers】

Read MoreHow much solids damage can the customer tolerate?

horizontal slurry pump suppliers...

horizontal slurry pump suppliers 【horizontal slurry pump suppliers】

Read MoreSlurry Pump

horizontal slurry pump suppliers...

horizontal slurry pump suppliers 【horizontal slurry pump suppliers】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

horizontal slurry pump suppliers...

horizontal slurry pump suppliers 【horizontal slurry pump suppliers】

Read MoreCustomised solutions

horizontal slurry pump suppliers...

horizontal slurry pump suppliers 【horizontal slurry pump suppliers】

Read MoreSlurry Pump

horizontal slurry pump suppliers...

horizontal slurry pump suppliers 【horizontal slurry pump suppliers】

Read More

Popular articles

- I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

- Non-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

- Slurry pipe diameter.

- Dredge Pump Features

- BCT Ceramic Slurry Pumps

- Flushing is defined as a fluid which is introduced into the seal cavity on the process fluid side, close to the seal face, and is normally used to cool and lubricate the seal face.

Latest articles

-

Settling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

-

As a pump supplier, Aier is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc. If you want to get more information about >best slurry pump wholesale, welcome to >contact us today or request a quote.

-

Slurry Pump

-

Magnetite mixing

-

Choosing the right slurry pump

-

testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

Links

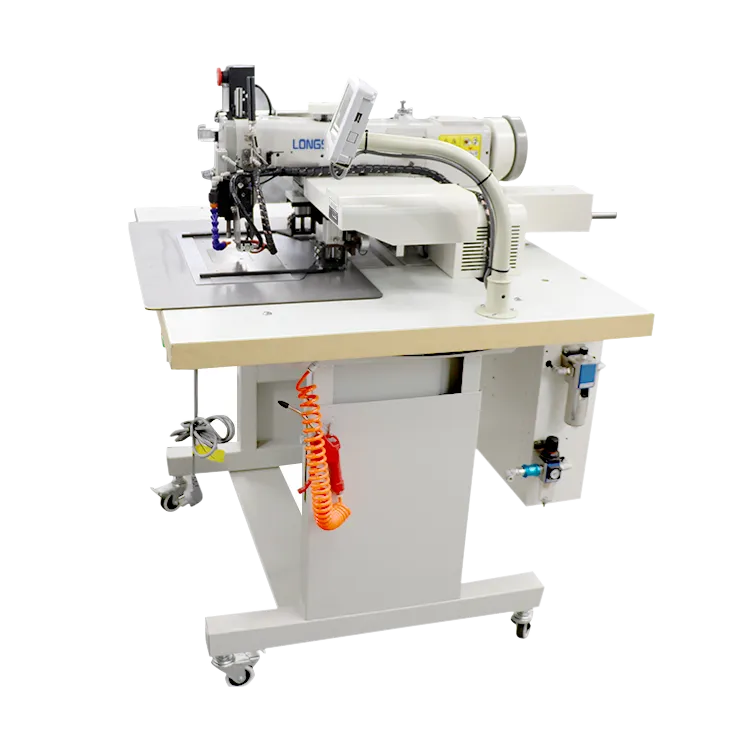

Advantages of Using Leather Stitching Machines

Just like any other piece of equipment, a sailmaker sewing machine requires regular maintenance to ensure optimal performance. Sailmakers are advised to clean their machines after each use, lubricating moving parts and checking for any wear on the needles or other components. Regular maintenance prolongs the life of the sewing machine and maintains its ability to produce high-quality stitches.

It’s also advisable to explore the option of purchasing used quilting machines. Many experienced quilters decide to upgrade their equipment and sell their previous machines at a fraction of the original price. This can be a great way to acquire a high-quality machine without breaking the bank. However, it’s important to thoroughly examine the condition of used machines and ensure that they come with proper documentation to guarantee their reliability.

Understanding Fully Automatic Sewing Machines

In addition to enhancing efficiency and reducing costs, these machines also prioritize safety and hygiene, especially in industries like food processing. Many automatic bag closer machines are equipped with features that comply with health and safety regulations, mitigating the risk of contamination. By automating the sealing process, the need for human contact with the product is minimized, ensuring that the integrity of the items remains intact.

Improved Consistency

As industries increasingly seek reliable and sustainable packaging options, the importance of PP woven bag stitching machines continues to rise. These machines not only streamline the production process but also ensure that the end product is both functional and environmentally friendly. Investing in advanced stitching technology can ultimately be a game-changer for manufacturers, positioning them at the forefront of the shifting packaging landscape. The integration of efficiency, cost reduction, and sustainability makes the PP woven bag stitching machine an invaluable asset in modern manufacturing practices.

Conclusion

leather canvas sewing machine. The presser foot can also be adjusted to accommodate different thicknesses of material, allowing for flexibility in the types of projects that can be completed with the machine.

In the world of manufacturing, particularly in the footwear industry, the advent of automatic shoe sewing machines has revolutionized the production process. These sophisticated machines have not only enhanced efficiency but also improved the quality of shoe manufacturing, paving the way for innovations that cater to both mass production and bespoke shoe creation.

2. Formation of the Loop As the needle rises, the top thread forms a loop above the fabric.

The Importance of Jumbo Belt Sew in Modern Fashion

Conclusion

The journey of creating a leather item begins with careful planning. Designers often sketch their ideas or use templates to ensure precision. Once the pattern is established, the leather is cut with great attention to detail. The edges are typically beveled and finished to prevent fraying and to enhance the overall appearance.

The Art of Upholstery Hand Sewing Machines A Blend of Tradition and Craftsmanship

Industrial zig zag embroidery machines find applications in various sectors, including fashion, automotive, and home furnishings. In the fashion industry, they are utilized to create intricate designs on garments, such as embellishments on dresses or logos on uniforms. In automotive manufacturing, these machines are essential for producing embroidered upholstery, seat covers, and custom insignias.

Climbing rope sewing machines are designed with features that accommodate the unique requirements of thick and resilient climbing rope materials. Unlike standard sewing machines, these specialized machines possess a robust construction that supports heavier threads and thicker fabrics. They feature high-powered motors and durable needles that can penetrate the toughest fibers without breaking.

Tips for Using a Double Needle Sewing Machine

Some thinner materials will require a special kind of stitch and also a lower ironing temperature. Thicker materials might also need to be sewn in layers. This process requires a powerful heavy duty sewing machine that can easily reach through the material without breaking or bending the needle.

Tailoring, perhaps one of the most precise forms of special sewing, focuses on creating fitted garments. This technique requires a deep understanding of body measurements, fabric behavior, and construction methods. Tailors use various stitches and seam types to ensure the perfect fit, elevating garments from mere clothing to tailored masterpieces. The use of specialized tools, such as dress forms and fabric shears, allows for attention to detail that distinguishes bespoke creations from off-the-rack pieces.

special sewing

In the world of textiles and garment manufacturing, the sewing machine has long been a cornerstone of the industry. Among the various types of sewing machines, the needle feed sewing machine stands out for its ability to enhance efficiency, accuracy, and versatility in fabric handling. This article explores the features, benefits, and applications of needle feed sewing machines, highlighting their significance in modern textile production.

- Versatility While primarily used for garment construction, sergers can also be employed for quilting, home décor projects, and even craft items. This versatility makes them a worthwhile investment for a wide range of sewing enthusiasts.

2. Pillow Covers

In conclusion, the coverstitch chain stitch is a valuable technique in the realm of garment construction. Its unique properties offer durability, flexibility, and an aesthetically pleasing finish, making it a go-to choice for a vast array of clothing styles, especially those crafted from knits and stretch fabrics. For anyone committed to improving their sewing skills and elevating their garment designs, mastering the coverstitch is an essential step towards achieving professional results.

Advantages of Industrial Sewing Machines for Home Use

Finding the Right Machine for Your Needs

Ideal for Various Projects

Advantages of Using a Handheld Leather Stitcher

While handheld sewing machines have many benefits, they do come with limitations. Their smaller size may reduce the workspace available for larger projects. They might lack some of the advanced features found in full-size sewing machines, such as extensive stitch libraries or the ability to handle very extensive or specialty sewing tasks.

what does an overlocker do. The machine is designed to work with materials like jersey, spandex, and Lycra, which can be challenging to sew with a regular machine. The overlocker's differential feed system helps to prevent stretching or puckering of the fabric, resulting in smooth, even seams that move with the body.