Jun . 30, 2024 12:10 Back to list

Warman Slurry Pump Design and Manufacturing Blueprint Overview

Understanding Warman Slurry Pumps A Glimpse into the Factory Drawings

Warman Slurry Pumps, a renowned name in the engineering industry, are specifically designed to handle abrasive and high-density slurries. These pumps, manufactured by Weir Group, are engineered for durability, efficiency, and resilience, making them indispensable in various sectors such as mining, power generation, and industrial waste management.

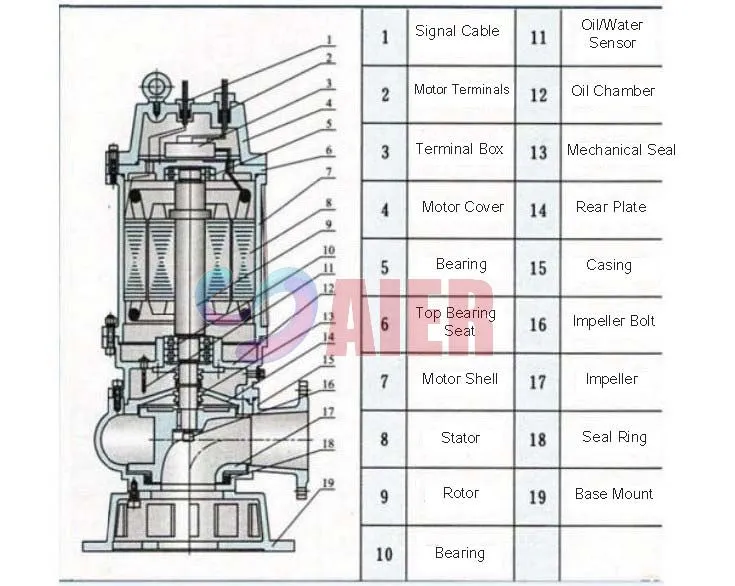

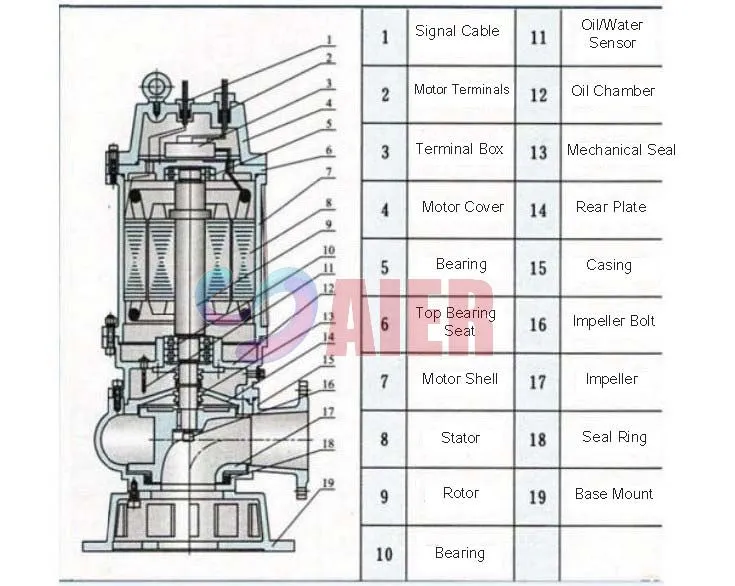

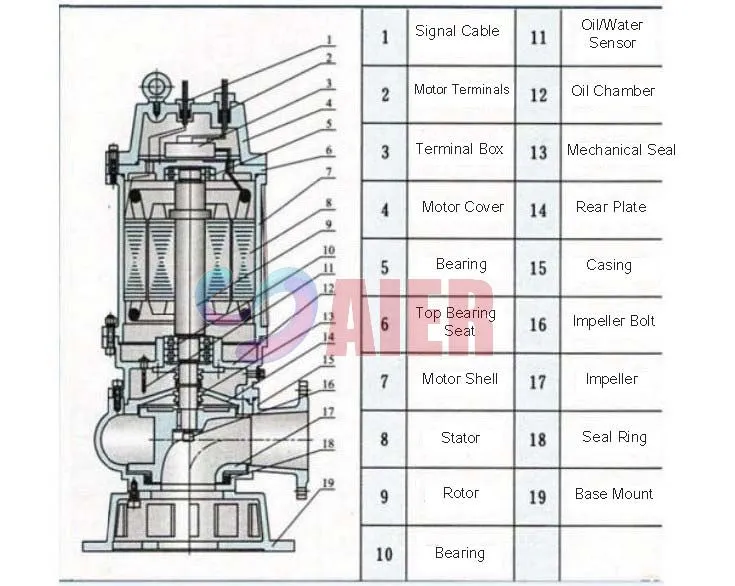

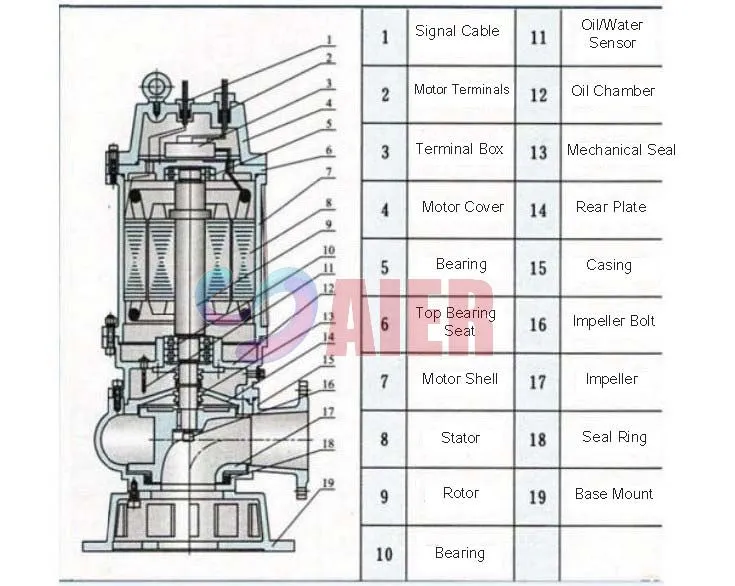

The design and construction of Warman Slurry Pumps are meticulously detailed in factory drawings. These drawings are the blueprint for the manufacturing process, encapsulating every intricate aspect from the pump's internal mechanisms to its external structure. They are not just illustrations but comprehensive technical documents that guide the production team through each step, ensuring precision and consistency.

Factory drawings for Warman Slurry Pumps typically include several key components. The main pump body drawing outlines the dimensions and material specifications for the casing, impeller, and other vital parts. It details the pump's suction and discharge ports, essential for fluid flow dynamics. The impeller drawing, another critical component, showcases the unique design that enables efficient slurry handling despite its abrasive nature.

The mechanical seal or gland packing drawings detail how these components prevent leakage and ensure a secure seal. The motor and coupling drawings provide specifications for the power source and transmission mechanism, while the foundation and installation drawings offer guidelines for proper setup and alignment.

Each drawing is accompanied by detailed notes, material codes, and tolerances, leaving no room for ambiguity

Each drawing is accompanied by detailed notes, material codes, and tolerances, leaving no room for ambiguity Each drawing is accompanied by detailed notes, material codes, and tolerances, leaving no room for ambiguity

Each drawing is accompanied by detailed notes, material codes, and tolerances, leaving no room for ambiguity

Each drawing is accompanied by detailed notes, material codes, and tolerances, leaving no room for ambiguity

Each drawing is accompanied by detailed notes, material codes, and tolerances, leaving no room for ambiguity warman slurry pump drawings factory. They also incorporate safety considerations, like appropriate lifting points and precautions during assembly, disassembly, and maintenance.

In the Warman factory, these drawings are more than just 2D representations; they come alive in the form of high-quality pumps. Skilled technicians interpret these drawings with precision, using state-of-the-art machinery and techniques to fabricate each part. Quality control measures are stringent, with regular inspections to ensure adherence to the drawings and the brand's high standards.

Moreover, the factory drawings also serve as a reference for service and repair teams. In case of any issues or the need for replacement parts, these drawings help identify the correct components swiftly and accurately.

In conclusion, Warman Slurry Pump factory drawings are the backbone of the manufacturing process. They are the embodiment of the pump's design philosophy, the roadmap for production, and a testament to the meticulous engineering behind these robust machines. Whether it's the initial construction or subsequent maintenance, these drawings play an indispensable role in ensuring the reliable operation of Warman Slurry Pumps in the demanding environments they serve.

warman slurry pump drawings factory. They also incorporate safety considerations, like appropriate lifting points and precautions during assembly, disassembly, and maintenance.

In the Warman factory, these drawings are more than just 2D representations; they come alive in the form of high-quality pumps. Skilled technicians interpret these drawings with precision, using state-of-the-art machinery and techniques to fabricate each part. Quality control measures are stringent, with regular inspections to ensure adherence to the drawings and the brand's high standards.

Moreover, the factory drawings also serve as a reference for service and repair teams. In case of any issues or the need for replacement parts, these drawings help identify the correct components swiftly and accurately.

In conclusion, Warman Slurry Pump factory drawings are the backbone of the manufacturing process. They are the embodiment of the pump's design philosophy, the roadmap for production, and a testament to the meticulous engineering behind these robust machines. Whether it's the initial construction or subsequent maintenance, these drawings play an indispensable role in ensuring the reliable operation of Warman Slurry Pumps in the demanding environments they serve.

Each drawing is accompanied by detailed notes, material codes, and tolerances, leaving no room for ambiguity

Each drawing is accompanied by detailed notes, material codes, and tolerances, leaving no room for ambiguity

Each drawing is accompanied by detailed notes, material codes, and tolerances, leaving no room for ambiguity

Each drawing is accompanied by detailed notes, material codes, and tolerances, leaving no room for ambiguity warman slurry pump drawings factory. They also incorporate safety considerations, like appropriate lifting points and precautions during assembly, disassembly, and maintenance.

In the Warman factory, these drawings are more than just 2D representations; they come alive in the form of high-quality pumps. Skilled technicians interpret these drawings with precision, using state-of-the-art machinery and techniques to fabricate each part. Quality control measures are stringent, with regular inspections to ensure adherence to the drawings and the brand's high standards.

Moreover, the factory drawings also serve as a reference for service and repair teams. In case of any issues or the need for replacement parts, these drawings help identify the correct components swiftly and accurately.

In conclusion, Warman Slurry Pump factory drawings are the backbone of the manufacturing process. They are the embodiment of the pump's design philosophy, the roadmap for production, and a testament to the meticulous engineering behind these robust machines. Whether it's the initial construction or subsequent maintenance, these drawings play an indispensable role in ensuring the reliable operation of Warman Slurry Pumps in the demanding environments they serve.

warman slurry pump drawings factory. They also incorporate safety considerations, like appropriate lifting points and precautions during assembly, disassembly, and maintenance.

In the Warman factory, these drawings are more than just 2D representations; they come alive in the form of high-quality pumps. Skilled technicians interpret these drawings with precision, using state-of-the-art machinery and techniques to fabricate each part. Quality control measures are stringent, with regular inspections to ensure adherence to the drawings and the brand's high standards.

Moreover, the factory drawings also serve as a reference for service and repair teams. In case of any issues or the need for replacement parts, these drawings help identify the correct components swiftly and accurately.

In conclusion, Warman Slurry Pump factory drawings are the backbone of the manufacturing process. They are the embodiment of the pump's design philosophy, the roadmap for production, and a testament to the meticulous engineering behind these robust machines. Whether it's the initial construction or subsequent maintenance, these drawings play an indispensable role in ensuring the reliable operation of Warman Slurry Pumps in the demanding environments they serve. Latest news

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025