12 月 . 05, 2024 17:40 Back to list

Warman Slurry Pump Design and Drawing Specifications for Reliable Suppliers

Understanding Warman Slurry Pumps A Comprehensive Overview for Suppliers

In the realm of industrial pumping solutions, Warman slurry pumps have garnered a reputation for their reliability and efficiency, particularly in the mining and mineral processing industries. This article aims to explore the essential aspects of Warman slurry pumps and provide insights into their design, drawings, and the role of suppliers in the global market.

What are Warman Slurry Pumps?

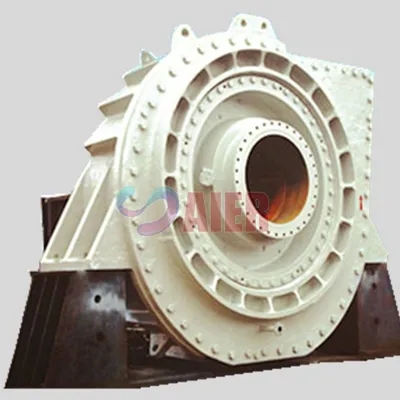

Warman slurry pumps are designed to handle abrasive and corrosive slurries, which are mixtures of water with fine particles of solid materials. These pumps are integral in applications such as coal handling, mineral processing, and waste management. They are characterized by their robust construction, which ensures durability and extended service life, even under the toughest operating conditions.

The Importance of Design and Drawings

The efficiency of any slurry pump lies in its design. Warman slurry pumps are engineered to optimize the flow of slurry while minimizing wear and energy consumption. The designs often include

1. Casing Typically made from materials such as high-chrome alloy, the pump casing plays a crucial role in protecting the internal components from abrasive wear. 2. Impeller The design of the impeller is critical as it affects the hydraulic performance. Warman pumps use various impeller designs to accommodate different types of slurries and operating conditions. 3. Volute The volute design ensures smooth transition of the slurry, reducing turbulence that can lead to wear and decreased efficiency. 4. Suction and Discharge The orientation and design of the suction and discharge ports are vital for minimizing pressure drop and ensuring maximum flow.

The technical drawings of these components are essential for manufacturers, suppliers, and end-users alike. They facilitate a thorough understanding of the pump's construction, allowing for proper installation, maintenance, and upgrades as needed.

warman slurry pump drawings supplier

Role of Suppliers in the Market

Suppliers play a vital role in the dissemination of Warman slurry pumps and their components. Their responsibilities include sourcing quality materials, maintaining inventory, and ensuring timely delivery of parts and finished pumps to customers. Here are some key functions suppliers perform

1. Quality Control Suppliers are tasked with ensuring that all products meet the stringent quality standards associated with Warman slurry pumps. This includes rigorous testing of materials and final products. 2. Customization Many clients require pumps tailored to specific operational needs. Suppliers work closely with manufacturers to offer customized solutions that meet the unique demands of each application. 3. Technical Support Adequate technical support is essential for both installation and troubleshooting. Suppliers often provide expertise in selecting the right pump model and configuration for a given application. 4. After-Sales Service The relationship between suppliers and customers does not end with the purchase. Suppliers must be prepared to offer after-sales services, such as maintenance, repairs, and replacement parts, to ensure continuous pump operation.

Trends and Innovations

As industries evolve, so too do the demands placed on slurry pumps. Recent trends in technology, such as the integration of IoT devices, aim to enhance monitoring and control of pump performance. Suppliers need to stay ahead of these innovations, ensuring that Warman slurry pumps are equipped with the latest advancements to improve efficiency, reduce downtime, and enhance safety.

Conclusion

Warman slurry pumps stand as a testament to engineering excellence in challenging industrial environments. The intricate designs represented in their technical drawings serve as a roadmap for effective functionality. Suppliers play an instrumental role in bridging the gap between manufacturers and end-users, ensuring that high-quality, reliable pumps are accessible. As industries continue to innovate and expand, the importance of understanding Warman slurry pumps and the suppliers who provide them becomes ever more crucial. Through collaboration and expertise, suppliers can help their clients achieve operational excellence, thereby driving productivity and growth in their respective sectors.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025