10 月 . 09, 2024 03:46 Back to list

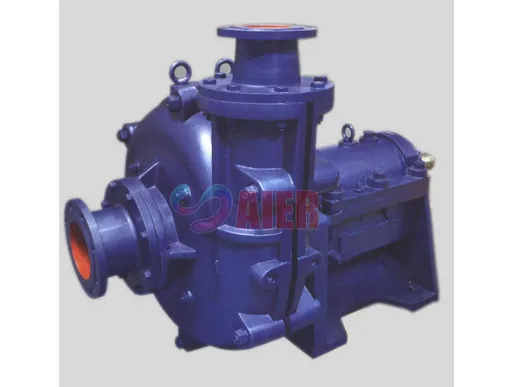

high quality slurry pump impeller type

The Importance of High-Quality Slurry Pump Impellers

In various industrial applications, slurry pumps play a crucial role in transporting abrasive and viscous materials. The efficiency and longevity of these pumps largely depend on the quality of their components, particularly the impellers. A high-quality slurry pump impeller is critical for ensuring optimal performance, reducing wear, and enhancing the overall lifespan of the pump. This article discusses the importance of impeller types in slurry pumps and how they contribute to operational efficiency.

Understanding Slurry Pumps and Their Applications

Slurry pumps are designed to handle a mixture of solids and liquids, commonly found in mining, mineral processing, dredging, and wastewater management. These pumps can efficiently transfer slurries, which can range from fine particles to coarse aggregates across varied distances. The impeller, a rotating component within the pump, plays a vital role in generating the hydraulic energy necessary to move the slurry.

Types of Impellers in Slurry Pumps

Impellers come in various designs and materials, each tailored to specific applications based on the slurry composition and operating conditions. The most common impeller types for slurry pumps include

1. Closed Impellers These impellers have a shrouded design that provides better efficiency and significantly reduces turbulence. They are ideal for slurries with minimal solid content, as they can produce higher discharge pressures.

2. Open Impellers Featuring a more straightforward design without shrouds, open impellers are suitable for handling slurries with high solid content. Their design allows for the passage of larger particles, which can be beneficial in heavy-duty applications.

3. Semi-Open Impellers A compromise between closed and open impellers, semi-open impellers are designed to handle slurries containing moderate solids. They provide improved efficiency over open impellers while still allowing for a certain degree of particle passage.

4. Variable Diameter Impellers These impellers can adjust their diameter and, consequently, the flow rate. This adaptability makes them ideal for applications with varying slurry characteristics.

Material Selection for Impellers

high quality slurry pump impeller type

The material used to construct the impeller significantly affects its performance and durability. Common materials include

- Cast Iron Known for its strength and corrosion resistance, cast iron is a popular choice for a wide range of slurry applications. - Stainless Steel Offering superior corrosion resistance, stainless steel is often used in applications with aggressive chemicals. - Rubber-lined Impellers Rubber provides excellent resistance to wear and impact, making it an ideal choice for handling abrasive slurries. - High-chrome Alloys These materials are designed for extreme wear resistance and are commonly used in mineral processing industries where abrasive materials are prevalent.

The Impact of High-Quality Impellers on Pump Performance

The performance of a slurry pump relies heavily on the impeller's design and material. High-quality impellers can lead to numerous benefits, including

- Increased Efficiency A well-designed impeller can enhance the hydraulic efficiency of the pump, allowing it to move more slurry with less energy consumption. This efficiency translates into lower operational costs and reduced wear on the pump.

- Extended Lifespan High-quality materials resist wear better than lesser alternatives, which means that pumps equipped with superior impellers are less likely to fail prematurely. This results in lower maintenance costs and fewer unplanned downtimes.

- Improvement of Operational Reliability Reliable impellers ensure consistent performance even under varying operating conditions. This reliability is essential in industries that cannot afford interruptions.

- Reduced Maintenance With improved durability and efficiency, high-quality impellers can minimize the need for frequent maintenance and parts replacement, leading to significant cost savings for organizations.

Conclusion

The selection of high-quality slurry pump impellers is a vital consideration for industries that rely on effective and efficient material transport systems. By understanding the various types, materials, and performance benefits of impellers, organizations can make informed decisions that enhance their operational efficiency and reduce costs. Investing in high-quality slurry pump components is not just a matter of performance; it's a commitment to sustainability and reliability in an increasingly demanding industrial landscape.

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025