Oct . 14, 2024 05:37 Back to list

Centrifugal Pump Manufacturing for Wastewater Management Solutions and Innovative Technologies

The Role of Centrifugal Wastewater Pump Factories in Modern Wastewater Management

In an age where environmental sustainability and efficient resource management are paramount, the role of centrifugal wastewater pumps has become increasingly critical. These pumps are essential in the treatment and transportation of wastewater, which has a direct impact on public health and environmental safety. This article explores the function, significance, and advancements of centrifugal wastewater pump factories in contemporary wastewater management systems.

Understanding Centrifugal Pumps

Centrifugal pumps operate on the principle of converting rotational kinetic energy, typically from a motor, into hydrodynamic energy, which moves the fluid. These pumps are designed with an impeller that spins, propelling the wastewater through the pump casing and into the discharge pipe. They are particularly suited for handling large volumes of fluids at relatively low pressures, making them ideal for wastewater applications.

The Importance of Wastewater Management

Effective wastewater management is crucial for safeguarding health and the environment. In urban areas, efficient drainage systems prevent flooding, protect water quality, and ensure that sewage is properly treated before being released into the environment. Centrifugal pumps play a crucial role in this process, transporting wastewater from collection systems to treatment facilities. The reliability and efficiency of these pumps directly influence the performance of wastewater treatment plants, which serve as the first line of defense against pollution.

The Role of Pump Factories

Centrifugal wastewater pump factories are specialized manufacturing facilities dedicated to producing high-quality pumps designed for handling various wastewater conditions. These factories employ advanced technology and manufacturing techniques to ensure that the pumps are robust, durable, and efficient. The design process often involves collaboration between engineers, environmental scientists, and manufacturing specialists to produce pumps that meet industry standards and customer requirements.

Key Features of Centrifugal Pumps

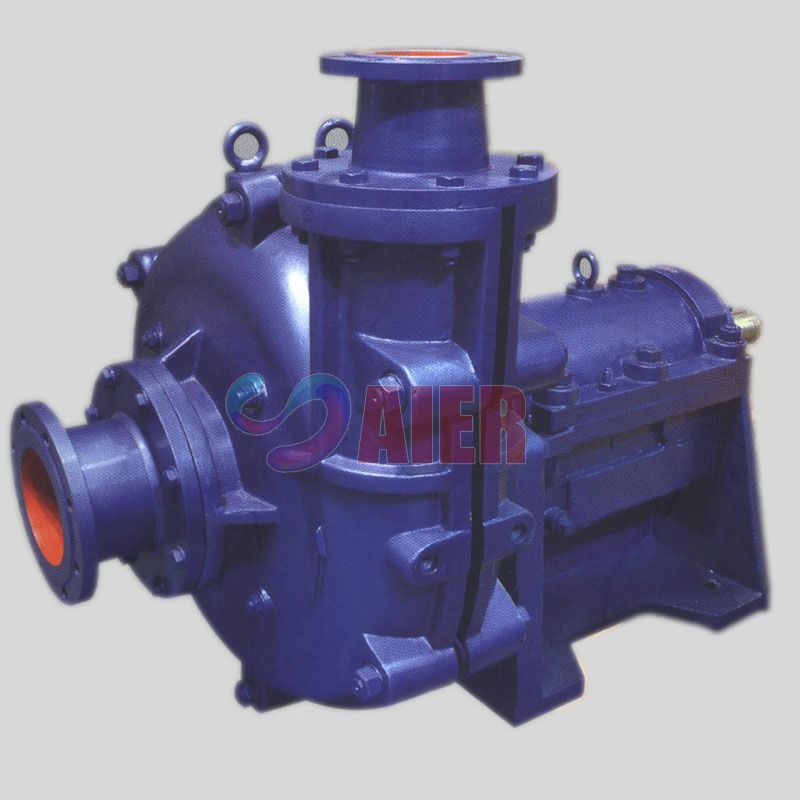

centrifugal wastewater pump factories

1. Durability Centrifugal pumps in wastewater applications must be resistant to corrosive materials and harsh operating conditions. Factories often use materials like stainless steel, bronze, or specialized polymers to enhance durability.

2. Efficiency Energy efficiency is a critical factor in pump design. Modern factories employ computational fluid dynamics (CFD) to optimize pump design, reducing energy consumption and operational costs.

3. Versatility Centrifugal pumps must be capable of handling various types of wastewater, including domestic sewage, industrial effluent, and stormwater. Factories can produce customized models tailored to specific applications.

4. Maintenance Ease of maintenance is crucial for minimizing downtime. Factories design pumps with features that facilitate quick and easy access to internal components, allowing for efficient servicing.

Innovations and Trends

The centrifugal pump manufacturing industry is not static; it continually evolves with technological advancements. One significant trend is the integration of smart technology. Many modern pumps come equipped with sensors and IoT capabilities, enabling real-time monitoring and predictive maintenance. This technology allows operators to receive alerts on pump performance, reducing the risk of failures and optimizing operational efficiency.

Moreover, sustainability is becoming a focal point in manufacturing practices.Factories are increasingly adopting eco-friendly manufacturing processes and materials, reflecting a broader commitment to environmental stewardship. This includes utilizing recycled materials, reducing waste, and implementing energy-efficient manufacturing processes.

Conclusion

Centrifugal wastewater pump factories play a pivotal role in the ecosystem of wastewater management. Their contribution goes beyond manufacturing; they help ensure that communities are equipped with the necessary infrastructure to manage wastewater effectively and sustainably. As cities continue to grow and environmental challenges escalate, these factories will be at the forefront of developing innovative solutions that enhance the efficiency and reliability of wastewater treatment systems. Investing in advanced centrifugal pumps and their manufacturing processes is not just a matter of operational necessity; it is a commitment to public health and environmental integrity. Through continuous innovation and adherence to quality, centrifugal wastewater pump factories will remain indispensable in the ongoing efforts to create cleaner, safer water systems.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025